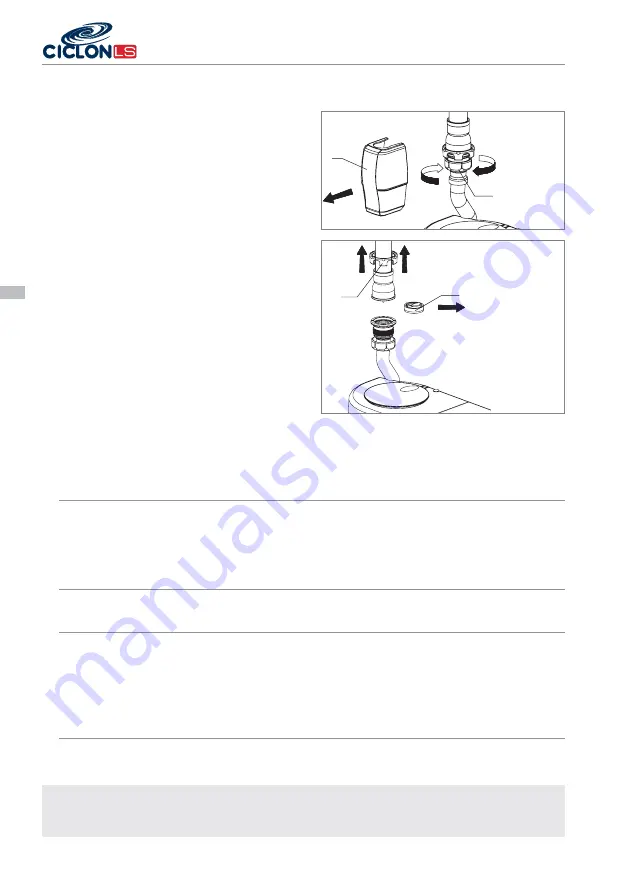

7.4. REPLACEMENT / CLEANING OF THE DISCHARGE NON-RETURN VALVE.

Before beginning the replacement / cleaning,

carry out a number of discharge cycles and (if

one has been installed) close the vertical drainage

pipe’s throttle valve and disconnect the unit from

the electricity supply.

- Remove the cover

and the 1

¼

” nut

.

- Loosen the clips of the discharge pipe brace in

order to be able to move the tube and thus enable

its disassembly.

- Prepare a container to collect the water, empty

the discharge pipe, activating the flapper of the

non-return valve.

- Remove the clip nut

- Check or replace the seal non-return joint

assembly.

- Follow the steps in reverse order to assemble the

valve.

Carry out a number of discharge cycles of the unit

before putting it back in service in order to eliminate

the air from the discharge installation.

8. TECHNICAL SPECIFICATIONS.

Inlets:

Top:

2 1

½

” x 40 mm inlets for Ø40 / 32 mm * smooth pipes

Lower side:

2 1

½

” x 40 mm inlets for Ø40 / 32 mm * smooth pipes

with non-return valve

Upper side:

1 1

½

” x 40 mm inlet for Ø40 / 32 mm * smooth pipes with

non-return valve.

* Five 40 to 32 conical reducing joints are supplied.

Outlet:

Discharge:

Ø32 mm for PVC pipe.

Non-return valve:

1

¼

” x 32 mm removable.

Pump:

Voltage:

~ 220/230 V, AC, 50 Hz.

Fuse:

Thermal.

Power:

0.39 kW.

Capacitor:

10 µF

Electrical connection:

For IEC standard

Maximum discharge height:

7 m

Maximum horizontal discharge distance:

72

Dimensions and weight:

Dimensions:

413 x 180 x 270.5 mm

Weight:

7.6 Kg

Weight including packaging:

8.9 Kg

12 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

English

NOTE: As a result of the constant improvement and development of our products, the data provided in this

maintenance and instruction manual may be modified without prior notice. This maintenance and instruc-

tion manual has no contractual value and all the information is given in good faith.

TO RETIRE EMBELLECEDOR

NON-RETURN JOINT

RENOVE CLIP NUT

REMOVE 1

¼

”

NUT