5.1. INSTALLATION RECOMMENDATIONS.

PIPING – Use Ø 32 mm PVC piping for discharge propulsion. Avoid curved sections (siphons) that

could retain certain solids and create obstructions.

PIPE SUPPORTS – The drainage pipes must be supported with the right accessories, according to

the manufacturer’s instructions.

BENDS – Do not use 90º elbows, use bends instead. If bends are not available, it is possible to use

two 45º elbows instead.

AVOID DIAGONAL SECTIONS – The installation sections must always be vertical or horizontal, never

install diagonal sections.

PROTECTION AGAINST FROST – In areas where there is a risk of frost due to

low temperatures, all stretches of pipe that are at risk of freezing must

be protected with thermal insulation.

CONNECTION WITH THE DOWNPIPE – Carry out the connection with the down-

pipe by means of a 45º bypass. If the joint with the downpipe is below the

base of the lifting station, a ventilation valve (Jimten A-69 type) must be

connected at the highest point of the installation to stop it emptying.

DISCHARGE – The discharge section must always be connected to the

drainage network or grey water tank. It is not recommended that the

water go into open drains or similar.

VENTILATION – The lifting station must not be enclosed by walls or in such a

way that the motor is prevented from being correctly ventilated by

means of the ventilation system incorporated.

SANITARY FIXTURES – The lifting station is prepared for the connection of up to

5 sanitary fixtures and appliances (washbasin, bidet, shower, bathtub,

MMAINTENANCE AND INSTRUCTION MANUAL - 7

LIFTING STATION EB-705

English

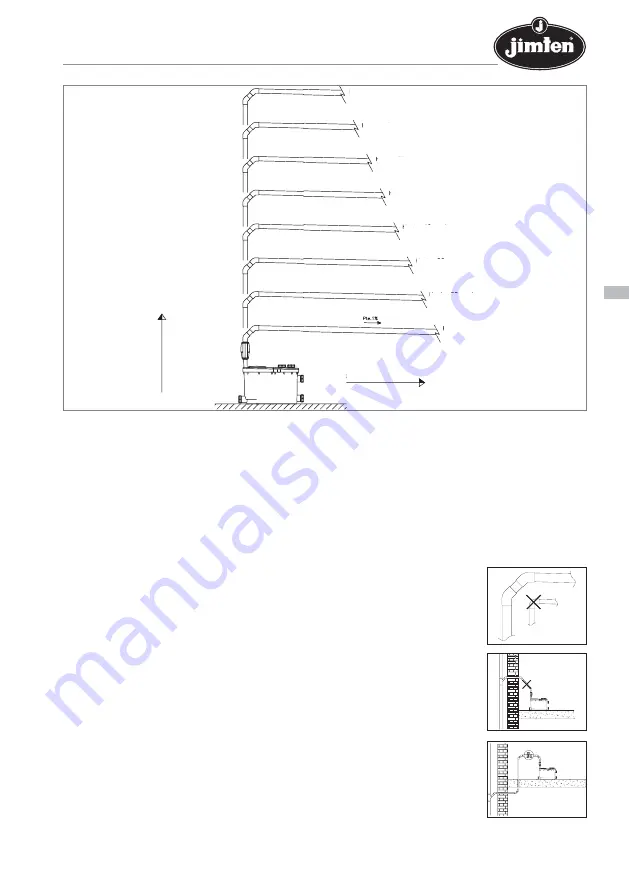

7 m.

6 m.

5 m.

4 m.

3 m.

2 m.

1 m.

0 m.

Up to 2 m.

Up to 12 m.

Up to 22 m.

Up to 32 m.

Up to 42 m.

Up to 52 m.

Up to 62 m.

Up to 72 m.

HORIZONTAL RANGE

VERTICAL RANGE