prevent risk of leakage. In areas with risk of frost, it is recommended to protect the water pipes with heat

isolation and anti-freeze liquids for plumbing.

CLEANNING:

It is recommended to use any cleaner without acid base formulation to clean all sanitary

appliances connected to the unit and the waste disposer. Lo prevent lime deposit, it is recommended to, on

a regular basis, disconnect from the power net the waste disposer, pour a mixture of 1 litre of vinegar and 3

litres of water (aprox.) through any connected sanitary appliance (washbasin, bidet or urinal), leave it act

some hours, connect the lifting station and switch it back on.

PROBLEM SOLUTION:

Verify that the connected elements work correctly and do not have leakages, check

that the waste disposer is correctly switched on its base and this base has power supply. Check the motor

heat protection has not acted (by waiting 20 minutes aprox. the unit should reset itself automatically).

MAINTENANCE AND INSTRUCTION MANUAL - 7

English

T-502 WASTE DISPOSER

For widespread version of this manual, visit www.jimten.com

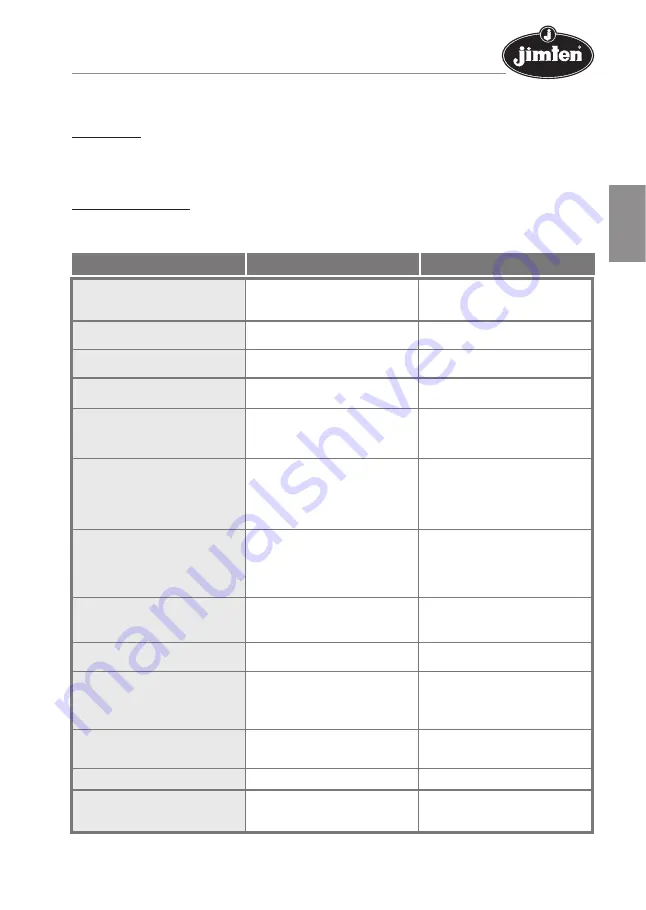

PROBLEM

CAUSE

SOLUTION

- The waste disposer does not start.

- It is disconnected.

- The electrical connection fails.

- The thermal protection circuit has been activated.

- Connect the unit properly.

- Check the electrical connection.

- Wait roughly 20 minutes until the motor cools.

- The differential switch trips.

- Motor earth wire is defective.

- Motor out of service. Contact the T.A.S.

- The motor works, but does not discharge or

makes it slowly.

- The evacuation pipe is obstructed

- Clean the evacuation pipe.

- The motor buzzes but does not spin.

- Turbines or blades blocked by foreign bodies.

- See the waste disposer dismantling

(E)

.

- After the evacuation, the motor starts and stops

indefinitely.

- Escapes in the non-return valve or water loss

from the cistern or from the auxiliary connection.

- Clean the non-return valve of the discharge pipe.

- Review and replace the joints of the cistern

discharger and those of the taps from the

connected sanitary appliances.

- The motor does not stop.

- Evacuation pipe is too high or long.

- Power loss due to too many elbows.

- The discharge pipe is obstructed.

- The discharge pipe is obstructed due to lime

remains.

- The micro-switch does not work properly.

- Review the evacuation installation.

- Review the evacuation installation.

- Perform the descaling process as described .

- Contact the T.A.S.

- The motor only works when the WC

is discharged but not with the water from the

other sanitary connected appliance.

- The auxiliary connection or the

non-return valve is blocked.

- The auxiliary connection lacks

ventilation.

- The micro-switch is not working properly.

- Clean the pipe stretches of the auxiliary

connection and the non-return valve.,

- Install a secundary ventilation, or a Jimten A-69

vac-vave. / Review the evacuation installation.

- Contact the T.A.S.

- After evacuating the motor starts

continuously before stopping.

- The water returns to the waste

disposer. The non-return valve

dos not work properly.

- Carry out several discharges with clean water

and clean the non-return valve.

- Accumulation of wastes inside

the lavatory.

- Unsuitable water supply from the cistern.

- Adjust the water level in the cistern

(6 litres minimum).

- The water returns to the shower base

- The required minimum slope at the evacuation

installation has not been attained (see shower

base height)

- The non-return valve of the auxiliary connection

does not work properly.

- Review the installation (rising the shower base

height)

- Clean and/or replace the item from the waste

disposer.

- Odd noises when the motor operates.

- Obstruction due to a foreign object in the lavatory.

- Extract the item from the waste

disposer (

(E)

. motor dismantling and removal)

- The shower base does not evacuate correctly.

- Corrosion of the active carbon filter.

- Replace the filter (contact the T.A.S.)

- Nasty smells coming from the waste disposer.

- Obstruction on the run pipe.

- Siphonic valve on the shower base, generates

an air piston on the pipe.

- Clean the pipe.

- Replace the shower base valve trap using a

non-siphonic valve.