15

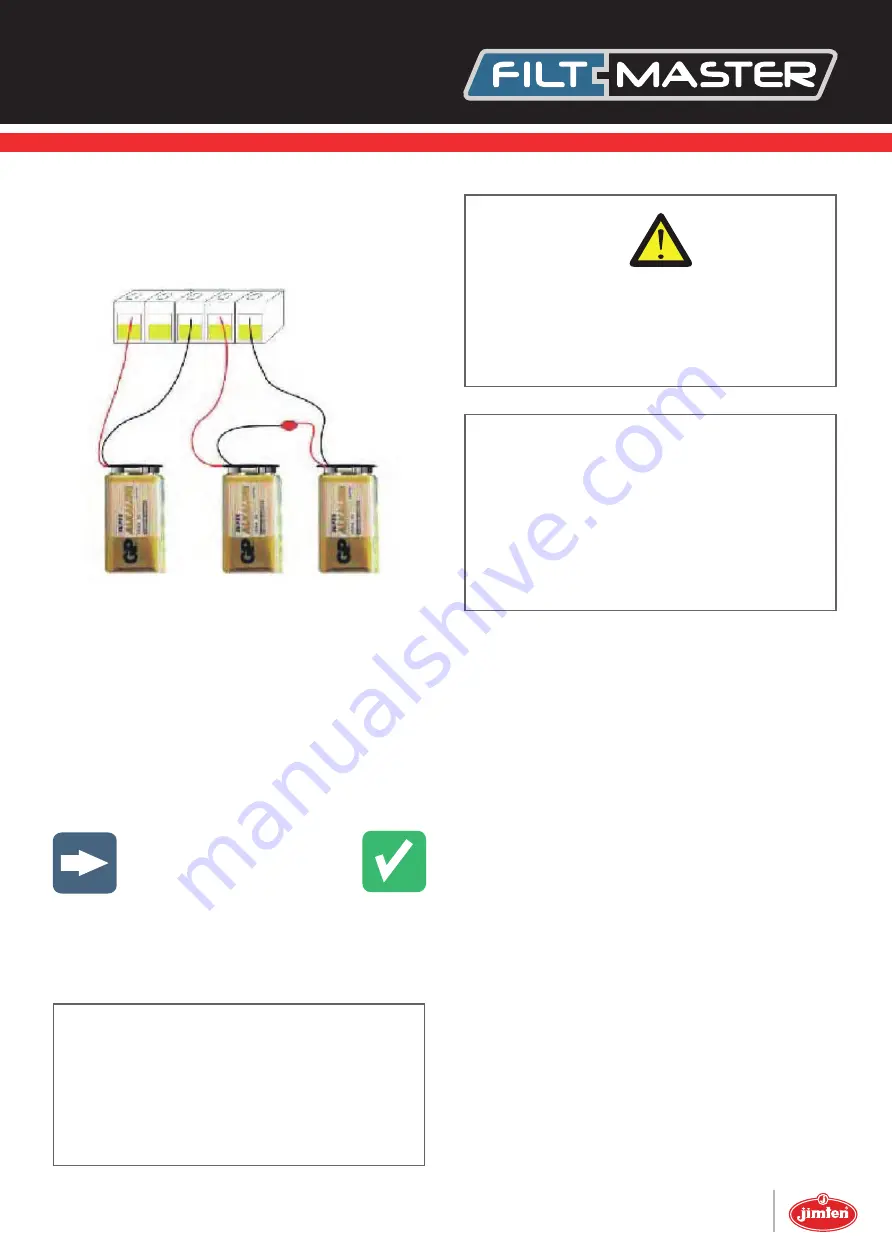

Most solenoids work from 9 to 12 Vdc, but there are

some cases when solenoids must be powered with a hig-

her voltage. In these cases, we can do as follows:

Once this operation is carried out, the screen shows the

controller status.

Another characteristic of this controller is that it discon-

nects its screen in order to save energy. If we want to

program it again, we must press any key for a few se-

conds until it activates again.

To turn it off again, we will key in at the ‘’STATUS

SCREEN’’:

When validating, the screen will turn off, but the contro-

ller will be fully operational.

NOTE

The specific operation of this kind of controller

and the fact that the low power consumption of

all its functions is a priority, make inadvisable ins-

tallations that require an active input since this

means multiplying the power consumption and

therefore reducing its autonomy.

NOTE

Due to the fact that the highest power consump-

tion occurs when the screen is on, after learning

how to operate the controller during the first

programming, we recommend to swap the two

batteries so that the battery in best condition is

available for the electronics.

9 Vdc

Sleep controller?

will be shown

9 Vdc

9 Vdc

18 Vdc

+

=

VERY IMPORTANT

Battery controllers switch the screen off to save

power consumption when no key has been touched

for a minute.

To switch on the screen again… Keep a key pres-

sed for a few seconds.

Electric connection to backwash valves

The connection to backwash valves is done through so-

lenoids. Current intensity must not exceed 1,6 Amp for

the total of solenoids connected simultaneously to the

output ports.

We must bear in mind that the internal transformer gives

a maximum intensity of 40VA, so we will take into con-

sideration the maximum power consumption, depending

on the number of solenoids and relays working simulta-

neously in the worst case scenario.

The Filtmaster filter cleaning controller can be connec-

ted either to continuous consumption solenoids or to

latch solenoids.

The connection is the same for 12 Vdc controllers, ta-

king into account the power supply polarity and the po-

larity of solenoids.