17

Furthermore, the installation of an external relay is good

because this increases the galvanic separation between

the solenoid and the controller. Another advantage is that

the relay can bequickly changed in case of breakdown.

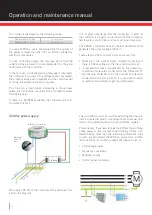

The devices shown on the previous table are those in the

following diagram:

In the previous diagram, we see the connections to the

water meter and the differential pressure gauge. These

inputs are fixed for these devices.

Electric connection to pumps

In addition to the controller, backwash valves and fil-

ters, there are other devices (pumps, mixers, fertilizer

pumps, etc.).

These elements are based on electric motors, and so

their installation and control follow common guidelines.

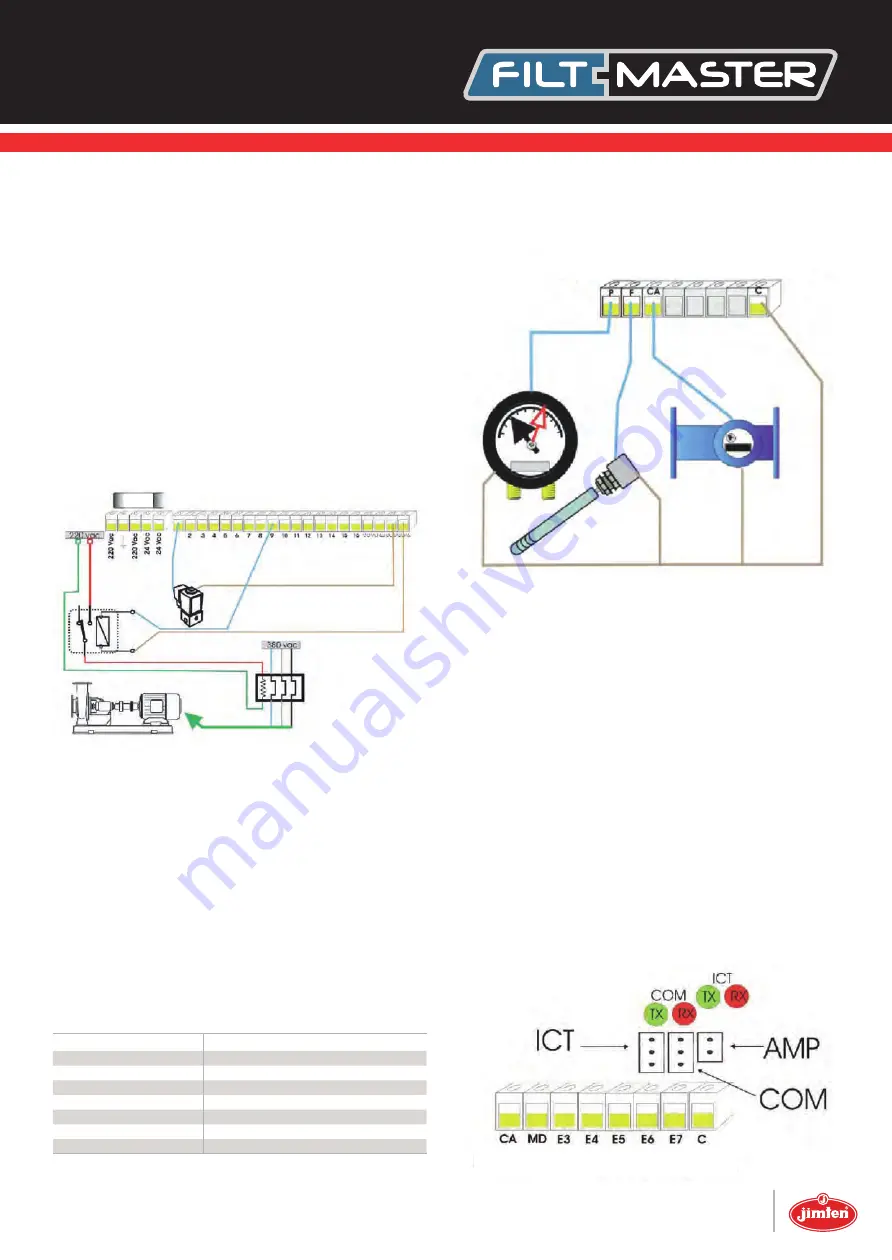

Communication connections

The controller can communicate with different devices:

There are 3 connector types located immediately above

the connection terminal block of the digital inputs.

There are 4 warning lights that inform us whether the

controller is sending or receiving information (from mo-

dem or ICT), useful information for setup and assistance

operations.

Input connection terminal block

The controller has 7 contact voltage-free inputs, that is

to say, the controller recognises them when there is a

short circuit between the common input and the corres-

ponding input.

The function of these inputs is the following:

The previous diagram is valid both for the automation

of pump motors, mixers and electric fertilizer injection

pumps.

Symbol

Function

P

MECHANICAL DIFFERENTIAL PRESSURE SWITCH

F

NETWORK WATER SENSOR/ACTIVE PUMPING

WM / CA

WATER METER

E4

-----without use-----

E5

-----without use-----

E6

-----without use-----

E7

-----without use-----

INPUTS

INPUTS

1,6 Amp