2

Operation and maintenance manual

Safety instructions

Filtration process

1

2

1. Read this Operation and Maintenance Manual before

working the automatic filtration station.

2. Make sure the filter is not pressurized before doing

any maintenance.

3. Handle with care while transporting or installing the

product.

4. Avoid any direct contact of water to electrical parts

during the installation.

5. Check that the operating conditions do not exceed the

recommendations of the manufacturer.

6. Check before installing that the pressure in the net-

work does not exceed the maximum working pressure

(10 bar).

7. The system can activate automatically the backwash

mode at any time without previous notice.

8. Use original spare parts for maintenance.

9. JIMTEN will take no responsibility for any modifica-

tions or use of non original spare parts.

ATTENTION

Before opening a single filter for maintenance,

make sure that it is not pressurized.

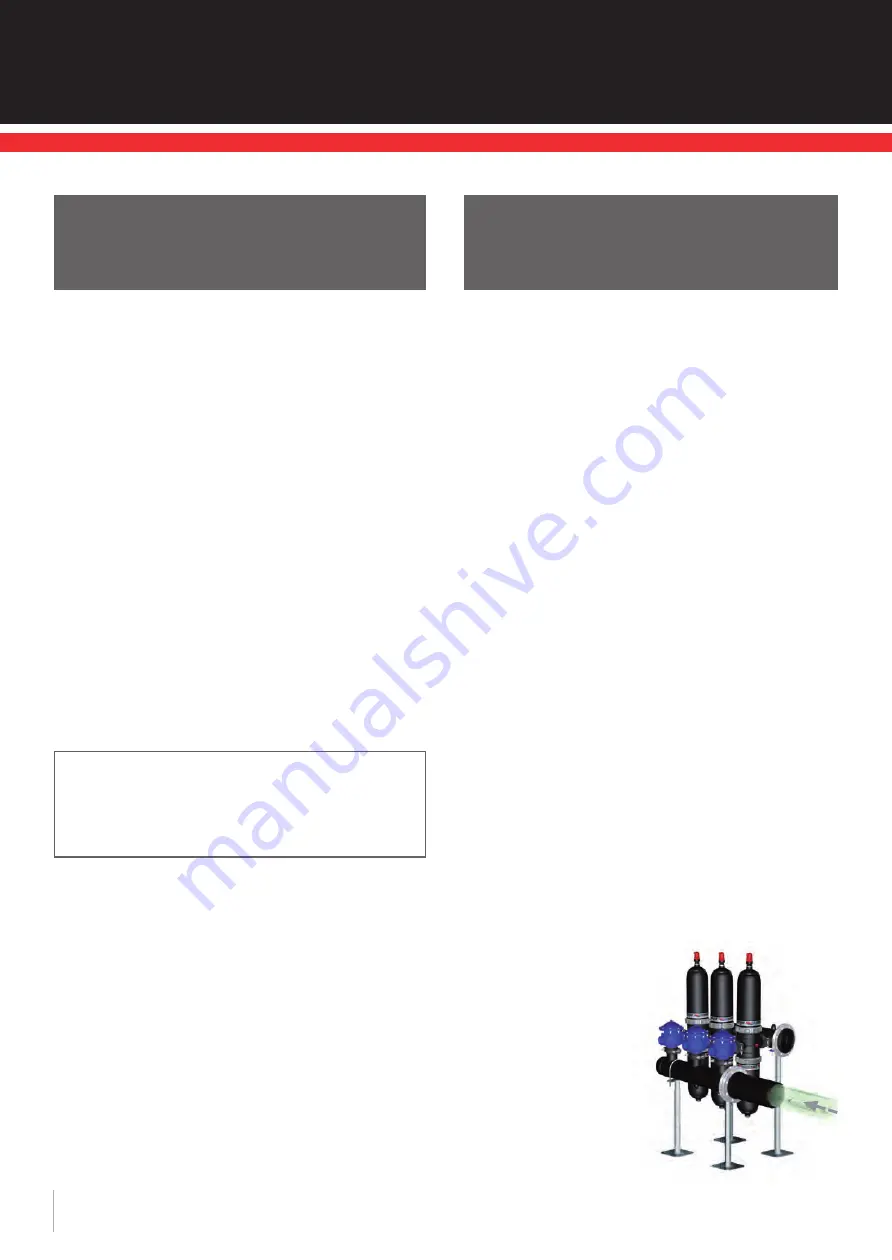

During the filtration phase, dirty water flows through the

inlet HDPE manifold and goes through the backwash

hydraulic valves into the Filtmaster disc filters, passing

through the discs to the outlet HDPE manifold.

Description of the backwash process

1. The controller transmits an electrical command to the

solenoid of the first filter according to either differen-

tial pressure or time.

2. The solenoid actuates on a hydraulic relay mounted

on the hydraulic backwash valve, changing the hy-

draulic valve from filtration to backwash position.

3. Filter number 1 is backwashed using clean water from

the outlet HDPE manifold that has been filtered by

the other filters in the automatic filtration station. Dir-

ty water and impurities flow out through the drainage

connection of the backwash valve to the HDPE drai-

nage manifold.

4. When backwash of filter number 1 is completed, ac-

cording to the program set up by the user, the filter

comes to filtration position.

5. Filter number 2 comes into backwash mode and the

process is repeated untill all the filters in the automa-

tic filtration station have been cleaned.

6. When all the filters have been cleaned, the automatic

filtration station goes back to filtration mode until the

next cleaning cycle starts.

Hydraulic connections

Dirty water

No automatic hydraulic

control valve should be

installed at the entrance

of the automatic filtration

station because it could

affect working pressure

conditions. If needed, we

recommend installing a

manual control valve.