20

Pr

=

0.0 atm pfc 08:32

NEXT V

=

0000 T

=

00:00 ti

Voltage (10%)

220 Vac

12 Vdc

9 Vdc

Power consumption 220 Vac / 12 Vdc/ 9 Vdc

75mA / 15mA / 400μA.

Power consumption per output

20 mA.

Power consumption per input

8 mA.

Internal battery

NI-CAD 3.6V 110mA/H

Duration of battery off

1 year

Working temperature

0ºC to 60ºC

Working humidity

0 to 95% non condensing

Power fuse

2 Amp

Outputs

RELAY

Output fuse

1,6 Amp

Output isolation

8 Amp 4mm

Inputs

Optocouplers

Input isolation

Optical

Overvoltage protection

Varistors

Problem

Action to be taken

The screen is off

- Check connection to power

- Check power is on

- Check fuses

A valve does not work

- Check that valve is active

- Measure the output voltage

No valve works

- Check output fuse

- Check possible short circuitin cables

Loses data

- Check the battery

- Change battery

Filters

CONTROLLER MODEL

(program version)

P

PRESSURE GAUGE ACTIVATED

Displayed when there is a need for cleaning through

this device.

C

WATER METER DETECTED

Displayed when it detects a meter pulse (if this device

exists).

F

CLEANING PERMISSION ACTIVATED

Displayed when it detects water in the network

(through minimum pressure swith, flow sensor, auxiliar

water pump or another controller). If water is detec-

ted, then cleaning is allowed.

Troubleshooting

Next, we offer users the best steps to follow when facing

an anomaly in the performance of our controller:

Components

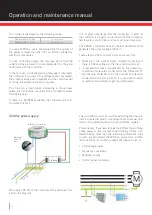

Digital display

The display allows us to program the cleaning process, to

set up the system adapting it to the needs of the installa-

tion and to check all its operating parameters.

On the “STATUS SCREEN”, the controller shows in real

time what is happening in the filtration station.

This information will be very important to set up the con-

troller, trying to achieve a balance between the correct

cleaning of the filters, water saving and the power con-

sumption saving (extremely important in battery operated

facilities).

The display has 2 lines with 20 characters each one.

Top line

Information regarding the model, status of the inputs and

current time.

If the problem is not solved, please contact your local

dealer or our aftersales department.

Users

manual

10

The Filtmaster filter cleaning controller is an easily pro-

grammable powerful device designed to process automa-

tically all the functions of a modern filtration station.

This version is able to control the automatic cleaning of 8

to 16 filters, depending on the model.

The high number of parameters that can be controlled by

the Filtmaster filter clenaing makes it adaptable to any

filtration system: from the most complex to the simplest.

The programming by the user (data input) through the

display allows an easy communication that makes the

use of this controller really simple and easy to unders-

tand by users.

Operation and maintenance manual