9

VERY IMPORTANT

In this manual we deal with operations that in

some cases may mean physical risk for the opera-

tor who carries out these operations.

Precautionary, 220Vac controllers must be opera-

ted when switched off.

All the operations must be carried out using the

appropriate tools and safety protection means.

with the right safety protection.

Installation manual

9

The 8/16 output Filtmaster filter cleaning controller is

capable of activating sequentially up to 16 valves depen-

ding on the model.

In this manual, we will cover the installation of the con-

troller and the electrical wiring to all elements to be con-

trolled.

This manual has been prepared by JIMTEN for the exclu-

sive use of its customers. It is understood that the user is

responsible for use.

Where to install the controller.

To protect the Filtmaster filter cleaning controller from

damage, it must be installed in a dry place and away from

heat or electrical noise sources.

Never expose to continuous sunlight the controller screen.

For optimum vision, place the screen at the user’s eye

level, or keep viewpoint at 90 degrees angle.

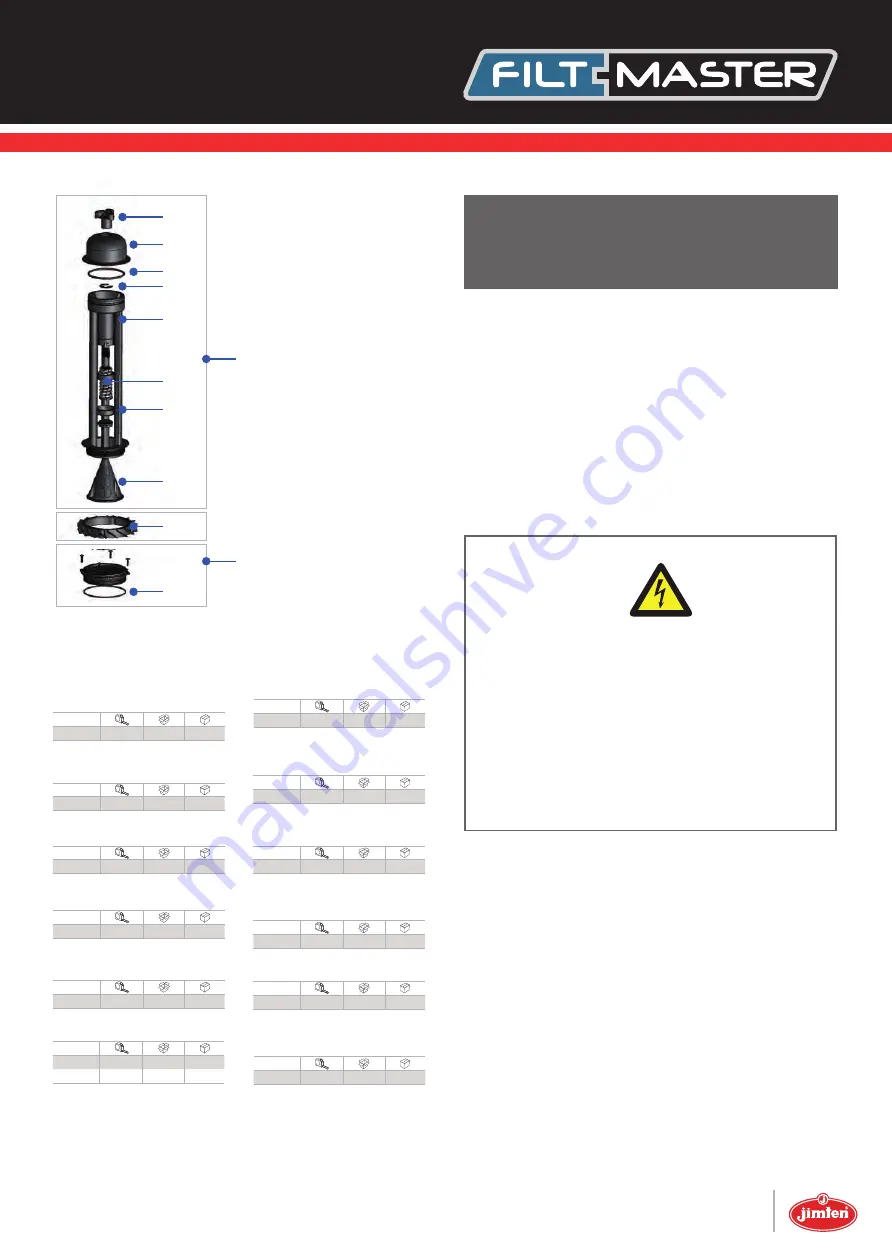

13.- Deflector crown

Code

97336

2”-3”

1

A-10

14.- Automatic filter adaptor kit

Code

98782

-

1

4112

15.- Anti-return valve for automatic filter

Code

98781

-

1

4109

19.- Closing cover with joint

Code

97761

-

1

-

21.- Hydraulic piston washer

Code

97763

-

1

-

22.- Hydraulic piston cover

Code

97765

-

1

A-10

23.- Conical joint for hydraulic pistons

Code

97764

-

1

-

24.- Plastic screw for automatic

disc cartridge

Code

97766

-

1

-

25.- Disc support

Code

97767

-

1

A-8

26.- Spine without discs for automatic

filters

Code

98796

-

1

A-8

24

22

23

21

20

25

19

15

13

12b

26

14

Code

97335

2”-3”

10

A-10

12b.- O-ring for automatic disc

cartridge and manual before 2015

20.- Axis/spring wih hydraulic piston

Code

97762

-

1

-

97833

low pressure

1

-