Tilga Insert

8

Tilga Insert

9

Installation

(Continued)

Operating your Jindara

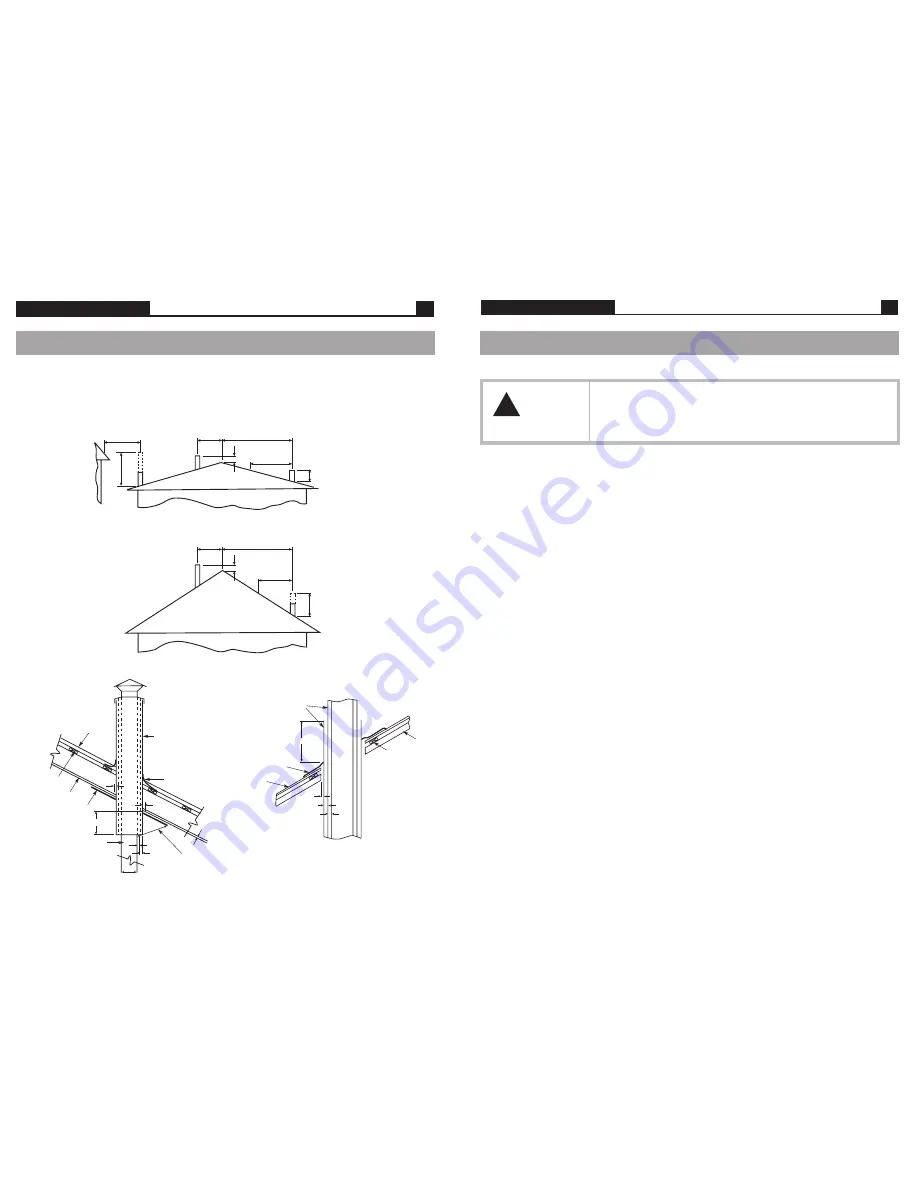

3000mm

3000mm

3000mm

1000mm

min if clear

within

3000mm of

flue top

Increase from

1000mm min

until clear

within 3000mm

of flue top

600mm min

More than 3000mm

600mm min

More than 3000mm

or less

3000mm

or less

Increase as

necessary

until

nothing

within

3000mm of

flue top

Any nearby

structure

3000mm

The flue pipe shall extend not less than 4.6m above the top of the floor protector. Note: Installation must be

carried out by a licensed installer in accordance with AS/NZS 2918:2001.

Flue pipe casing

Flashing

3 x flue diameter

from active flue to

heat sensitive

surface

Batten

Flue

pipe

Flashing

Flue pipe casings

Heat sensitive roof

25mm

25mm

25mm

Flue pipe

Gap 25mm

Gap 25mm

Roofing

Batten

Ceiling

Ceiling Plate

See clause 4.6.3(b) of AS/NZS 2918:2001

25mm

12mm

25mm

150mm dia

Example of sloped ceiling penetration

Example of roof penetration

Rafter

See clause 4.8 of AS/NZS 2918:2001

Flue and chimney requirements

Figure 7

Figure 8

WARNING

!

DO NOT ATTEMPT TO OPERATE THIS APPLIANCE WITHOUT READING AND

UNDERSTANDING THESE OPERATING INSTRUCTIONS THOROUGHLY. FAILURE TO

OPERATE THIS APPLIANCE PROPERLY MAY CAUSE UNDUE DAMAGE TO THE

APPLIANCE OR RESULT IN A FLUE FIRE.

Read these instructions

Starting your fire

Place a firelighter or paper in the bottom of the firebox and place a large amount of small kindling on top. Ignite the

paper or the firelighter. Set the air control to high and leave the main door open approximately 25mm. When the kindling

is burning, place about four pieces of small wood on top of the burning kindling. Once the wood is alight, close the main

door. After approximately 20 minutes, turn the air control down to medium. For fan operation refer page 10.

On the initial fire up you may detect smoke coming from the paint finish and from any oils that may be on the steel on

the outside of the firebox. This is normal. It is suggested to well ventilate your home on the initial fire up. Please refer to

our section ‘Paint Curing and Care’ on page 2.

The glass door

Always operate your heater with the door closed and locked. The only time you can leave the door open is on initial

lighting, or when reloading the heater.

Care of your glass

If you are burning good dry wood, you will have very little discolouration of your glass in normal burning cycle. If you aim

for an eight to ten hour overnight burn, you should not get much discolouration. You can control this by adjusting the air

control, moving from the left and slowly creeping the control to the right. After a number of days you will find the right

position to suit your requirements and the fuel that you are using.

Daily operations

When you get up in the morning, open up the air control of the heater to high position to start the embers glowing. Place

three or four pieces of wood on top of the embers and leave the door open 25mm. Once the fuel starts to flame close the

door. Depending on your daily heating requirements, operate the fan as per fan operation instructions on page 10.

For best results it is best to burn 410mm long wood and load your wood straight into the firebox front to rear. This will

give optimum efficiency and recoverable heat, and minimise creosote formation and smoke emissions.

Overnight burn

Approximately 30 minutes before turning the heater down for the overnight burn it is recommended to load the heater with

fuel. Leave the air control in the medium to high position. Let the heater run for about 30 minutes. This will reduce the

moisture content in the fuel before shut down. (This will help reduce the creosote formation in the firebox and flue.)

Set the air control to the setting you have found best for your requirements. Turn the fan off or to the thermostat control

position and retire. The aim when overnight burning is to have only a few hot embers left in the bottom of the firebox in

the morning, not huge lumps of wood.