16

113242-3

Important

Coil failure due to improper pH level will void the

warranty.

Steam Requirements

Shaded areas are stated in metric equivalents

* The minimum operating pressure is 100 psig (689.47 kPa) for optimum results.

Installation Instructions

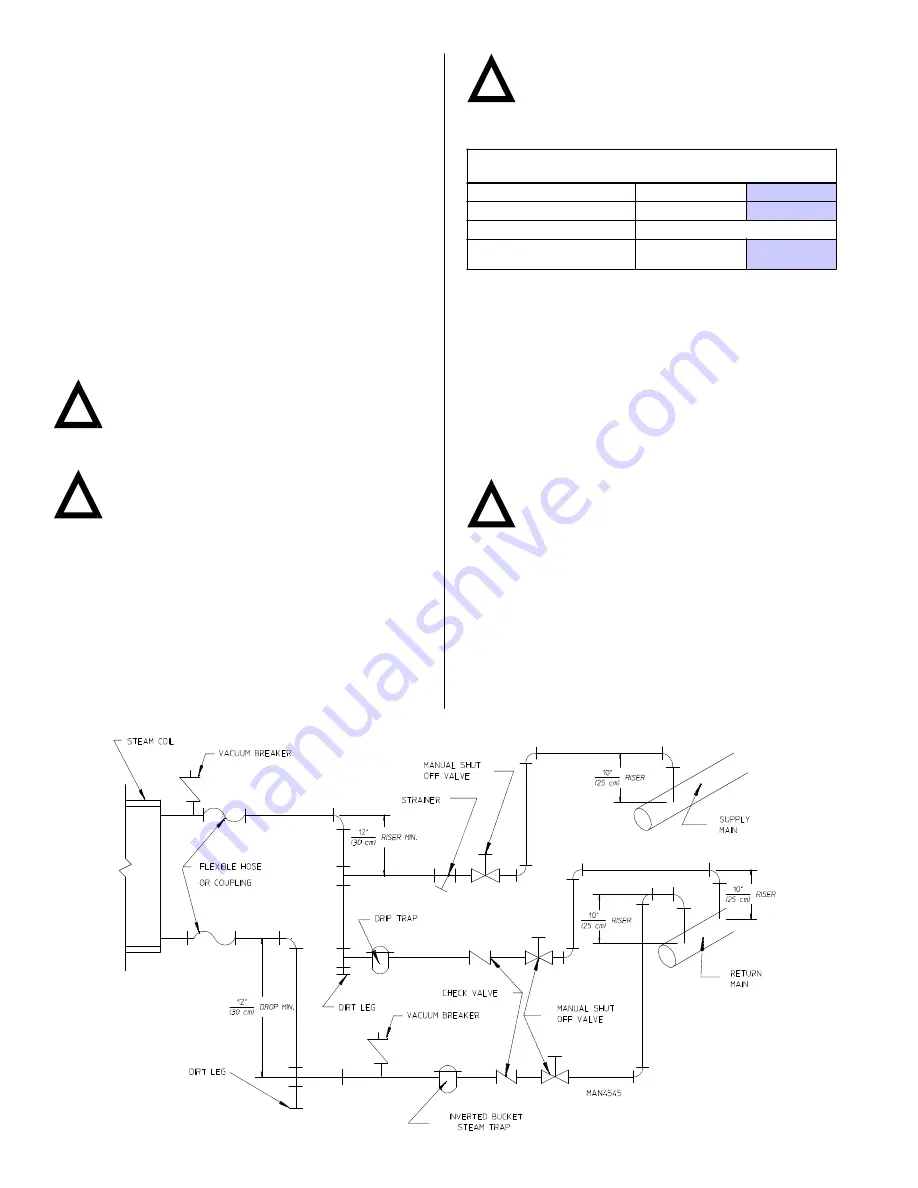

To ensure an adequate supply of steam is provided, be sure

that the steam supply lines and steam return lines are sized

and laid out as stipulated in this manual. Inadequate steam

supply lines and steam return lines or improper steam

plumbing will result in poor performance and can cause

component failure. Clean, dry steam must be provided to the

dryer.

Important

Steam coil failure due to water hammer by wet

steam will void the warranty.

The pressure of the condensate in the steam supply line will

cause water hammer and subsequent heat exchanger

(steam coil) failure. The steam supply connection into the

main supply line must be made with a minimum 10-inch

(25.4 cm) riser. This will prevent any condensate from draining

towards the dryer.

The steam supply line to the dryer must include a

12-inch (30.48 cm) riser along with a drip trap and check

valve. This will prevent any condensate from entering the

steam coil.

Operating Steam Pressure

Maximum

150 psig

862 kPa

Recommended

100 psig*

689 kPa

Heat Input (Normal Load)

3.0

bhp

Consumption (Approximate)

@ 125 psi (8.6 bar)

104

lbs/hr

47.17 kg/hr

!

!

!

!

Steam Information ___________________

It is your responsibility to have all plumbing connections made

by a qualified professional to ensure that the steam plumbing

installation is adequate and conforms with local and state

regulations or codes.

Care must be exercised when leveling steam dryers into final

position. After leveling the dryer, check the downward pitch of

the heat exchanger from front to rear with a level. Likewise,

check the downward pitch of the return condensate manifold

toward its outlet part. Absence of these downward pitches

will result in probable water hammer and premature heat

exchanger fracture and leakage.

The presence of condensate in the steam will cause water

hammer and subsequent heat exchanger failure. The steam

supply connection must be taken from the top of a

well-dripped steam main. If the supply run-out to the dryer

exceeds 20 feet (6.1 meters), it should be dripped just before

the control valve with a proper trap and dirt pocket.

Important

Failure to comply with the requirements

stipulated in this manual can result in component

failure, which will void the warranty.

Note

This dryer is manufactured with a pneumatic

(piston) damper system, which requires an

external supply of air (80 psi ± 10 psi [5.51 bar ± 0.68 bar]).

Steam Coil pH Level

The normal pH level for copper type steam coils must be

maintained between a value of 8.5 to 9.5. For steel type

steam coils the pH level must be maintained between a value

of 9.5 to 10.5. These limits are set to limit the acid attack of

the steam coils.