SECTION 2 - PREPARATION AND INSPECTION

2-4

– JLG Lift –

3120889

Platform

1.

Check platform and control console for damage,

loose or missing parts, and security.

2.

\Check control switches and levers for damage,

loose or missing parts and security. Assure that all

levers function properly.

3.

Check control switches, levers and electrical con-

nections for tightness and evidence of corrosion,

and wiring for defects and chafing damage. Assure

that all switches function properly.

4.

Check access gate hinges and latch for proper

operation, damage and security.

5.

Check platform rotator mechanism for proper opera-

tion, damage, security. Check hydraulic lines for

leakage, damage and security.

NOTE: Check all DANGER, WARNING, CAUTION and

INSTRUCTION placards for legibility and security on

the entire machine.

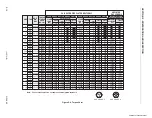

Torque Requirements

The Torque Chart (See Figure 2-6.) consists of standard

torque values based on bolt diameter and grade, also

specifying dry and wet torque values in accordance with

recommended shop practices. This chart is provided as

an aid to the operator in the event he/she notices a condi-

tion that requires prompt attention during the walk-around

inspection or during operation, until the proper service

personnel can be notified. The Service and Maintenance

manual provides specific torque values and periodic

maintenance procedures with a listing of individual com-

ponents. Utilizing this Torque Chart in conjunction with the

preventive maintenance section in the Service and Mainte-

nance manual will enhance safety, reliability, and perfor-

mance of the machine.

2.4

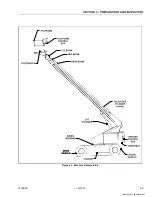

DAILY WALK-AROUND INSPECTION

It is the operator’s responsibility to inspect the machine

before the start of each workday. It is recommended that

each operator inspect the machine before operation, even

if the machine has already been put into service under

another operator. This Daily Walk-Around Inspection is the

preferred method of inspection. (See Figure 2-2.)

In addition to the Daily Walk-Around Inspection, be sure to

include the following as part of the daily inspection:

1.

Overall cleanliness.

Check all standing surfaces for oil, fuel and hydrau-

lic oil spillage and foreign objects. Ensure overall

cleanliness.

2.

Placards.

Keep all information and operating placards clean

and unobstructed. Cover when spray painting or

shot blasting to protect legibility.

3.

Operator’s and Safety Manual.

Ensure a copy of this manual and the ANSI A92.5-

1992 Responsibilities, are enclosed in the manual

storage box.

4.

Machine Log.

Ensure a machine operating record or log is kept,

check to see that it is current and that no entries

have been left uncleared, leaving machine in an

unsafe condition for operation.

5.

Start each day with a full fuel tank.

TO AVOID INJURY, DO NOT OPERATE A MACHINE UNTIL ALL

MALFUNCTIONS HAVE BEEN CORRECTED. USE OF A MALFUNC-

TIONING MACHINE IS A SAFETY VIOLATION.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS

“OFF” DURING WALK-AROUND INSPECTION.

NOTE: Check boom horizontal limit switch for proper opera-

tion and security, both visually and manually. Switch

must shut down high engine and high drive speed

when boom is raised above horizontal:

6.

Check platform footswitch for proper operation.

Switch must be released to start engine and

depressed to operate machine.

7.

Check that drive brakes hold when machine is

driven up a grade and stopped.

NOTE: On new machines, those recently overhauled, or

after changing hydraulic oil, operate all systems a

minimum of two complete cycles and recheck oil

level in reservoir.

8.

Assure that all items requiring lubrication are ser-

viced. Refer to Table 2-1, Lubrication Chart, for spe-

cific requirements.

Summary of Contents for 100HX

Page 2: ...Courtesy of Crane Market...

Page 4: ...FOREWORD b JLG Lift 3120889 This page left blank intentionally Courtesy of Crane Market...

Page 6: ...FOREWORD d JLG Lift 3120889 REVISON LOG January 1999 Original Issue Courtesy of Crane Market...

Page 78: ...Courtesy of Crane Market...

Page 79: ...Courtesy of Crane Market...