SECTION 1 - MACHINE SPECIFICATIONS

1-4

– JLG Lift –

3121228

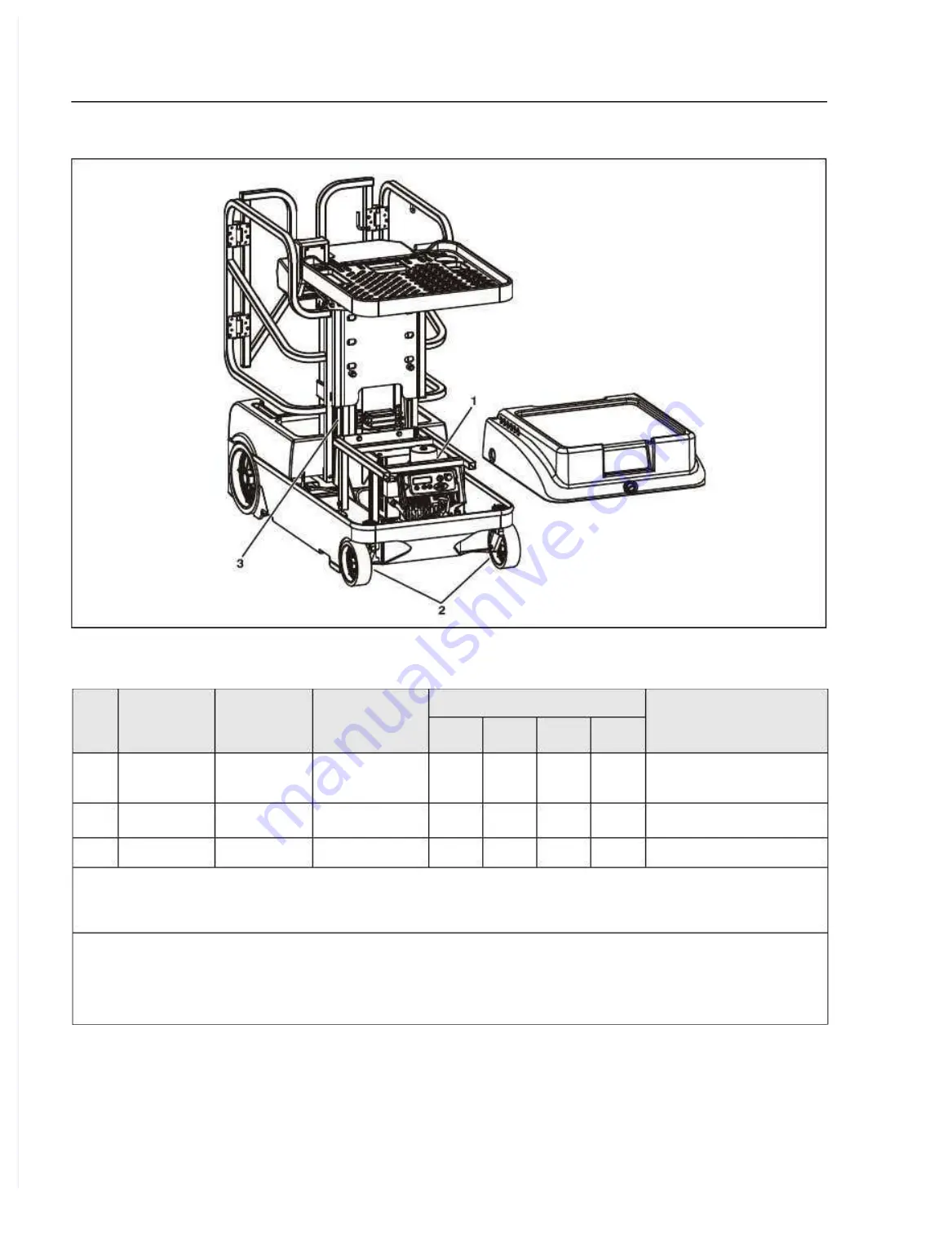

Lubrication Points.

(See Table Below)

Table 1-6. Lubrication Intervals for Various Components

ITEM

COMPONENT

NO/TYPE (a)

LUBE POINTS

LUBE/METHOD

INTERVAL

(b)

COMMENTS

3

MONTHS

6

MONTHS

1

YEAR

2

YEARS

1

Hydraulic Oil

Fill To Full Line on

Dipstick - 5 Qt.

Reservoir

HO - Check Hyd. Oil

Level

HO - Change Hyd. Oil

✔

Check fluid level every day.

(c)

Change hydraulic oil every 2 years.

2

Swivel

Raceways

—

MPG

✔

Upper: Permanently Sealed.

Lower: Repack if Serviced.

3

Mast Chains

2 - Per Section

CL - Brush or Spray

✔

Inspect, lubricate if dry or rusting.

Key to Lubricants:

MPG

- Multipurpose Grease

HO

- Hydraulic Oil - ISO-Vg grade 32, 46

GEAR OIL

- Good Quality Worm Gear Oil - SAE 90 - AGMA#5 - EP Compounded

CL

- Chain Lube. Use a good quality chain lubricant

Notes:

(a)

Be certain to lubricate like items on each side of the machine.

(b)

Recommended lubricating intervals are based on normal use. If machine is subjected to severe operating conditions,

such as a high number of cycles, location, corrosive/dirty environment, etc., user must adjust lubricating requirements accordingly.

(c)

Prior to checking hydraulic oil level, operate machine through one complete cycle of lift function (full up and down). Failure to do so

will result in incorrect oil level reading on the hydraulic reservoir.