SECTION 2 - GENERAL SERVICE INFORMATION

3121228

–

JLG

Lift

–

2-7

are on the verge of cracking. Fatigue and ultimate

strength failures on JLG Lifts are incurred as a result of

severe abuse as design specs are well within the rated lift-

ing capacity of these chains.

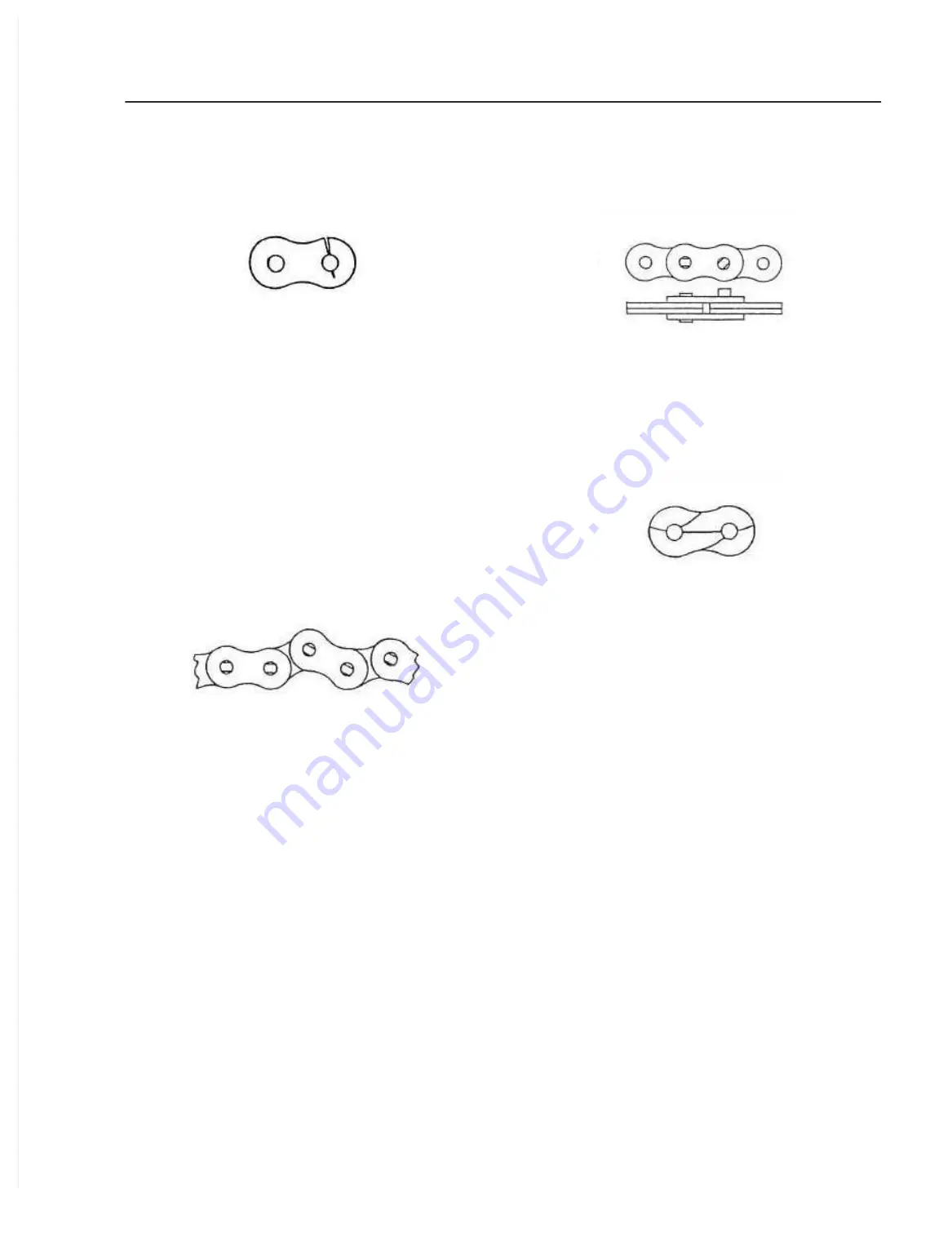

Tight Joints:

All joints in the leaf chain should flex freely.

On leaf chain, tight joints are usually caused by rust/corro-

sion, or the inside plates “walking” off the bushing. Limber

up rusty/corroded chains

(after inspecting care fully)

with

a heavy application of oil

(preferably a hot oil dip)

. Tap

inside “walking” plates inward; if “walking” persists,

replace the chain. This type of problem is accelerated by

poor lubrication maintenance practice, and most tight

joint chains have been operated with little or no lubrica-

tion. Tight joints on leaf chain are generally caused by:

a. Bent pins or plates.

b. Rusty joints.

c. Peened plate edges.

Oil rusty chains, and replace chains with bent or peened

chain components. Keep chains lubricated.

Protruding or Turned Pins:

Chains operating with inade-

quate lube generate tremendous friction between the pin

and plates (pin and bushing on leaf chain). In extreme

cases, this frictional torque can actually turn the pins in

the outside press-fit plates. Inspect for turned pins, which

can be easily spotted as the “V” flats on the pin heads are

no longer in line. Replace all chains showing evidence of

turned or protruding pins. Keep chains lubricated.

Stress Corrosion Cracking:

The outside link plates,

which are heavily press-fitted to the pins, are particularly

susceptible to stress corrosion cracking. Like fatigue

cracks, these initiate at the point of highest stress (aper-

ture) but tend to extend in an arc-like path, often parallel to

the rolling grain of the material.

Als o, mor e the n one cra ck can often app ear on a lin k

plate. In addition to rusting, this condition can be caused

by exposure to an acidic or caustic medium or atmo-

sphere. Stress corrosion is an environmentally assisted

failure. Two conditions must be present; corrosive agent

and static stress.

In the chain, static stress is present at the aperture due to

the press fit pin. No cycle motion is required and the

plates can crack during idle periods. The reactions of

many chemical agents (such as battery acid fumes) with

hardened metals liberate hydrogen which attacks and

weakens the metal grain structure.

Chain Anchors and Sheaves:

An inspection of the chain

must include a close examination of chain anchors and

sheaves. Check chain anchors for wear breakage and

misalignment. Anchors with worn or broken fingers should

be replaced. They should also be adjusted to eliminate

twisting the chain for an even load distribution.

Inspect the sheaves, sheave bearings, sheave grooves

and pins for extreme wear, replace as necessary. A worn

sheave can mean several problems, as follows:

a. Chains too tight.

b. Sheave bearings/pin bad.

c. Bent/misaligned chains.

TIGHT JOINTS

ABNORMAL PROTRUSION OR

TURNED PINS

ARC-LIKE CRACKED PLATES

(STRESS CORROSION)