SECTION 3 - USER RESPONSIBILITIES & MACHINE CONTROLS

3120751

– JLG Lift –

3-5

9.

WARNING HORN PAD

If machine is equipped with

(optional)

mounted

horn, this pad when pressed sounds the horn.

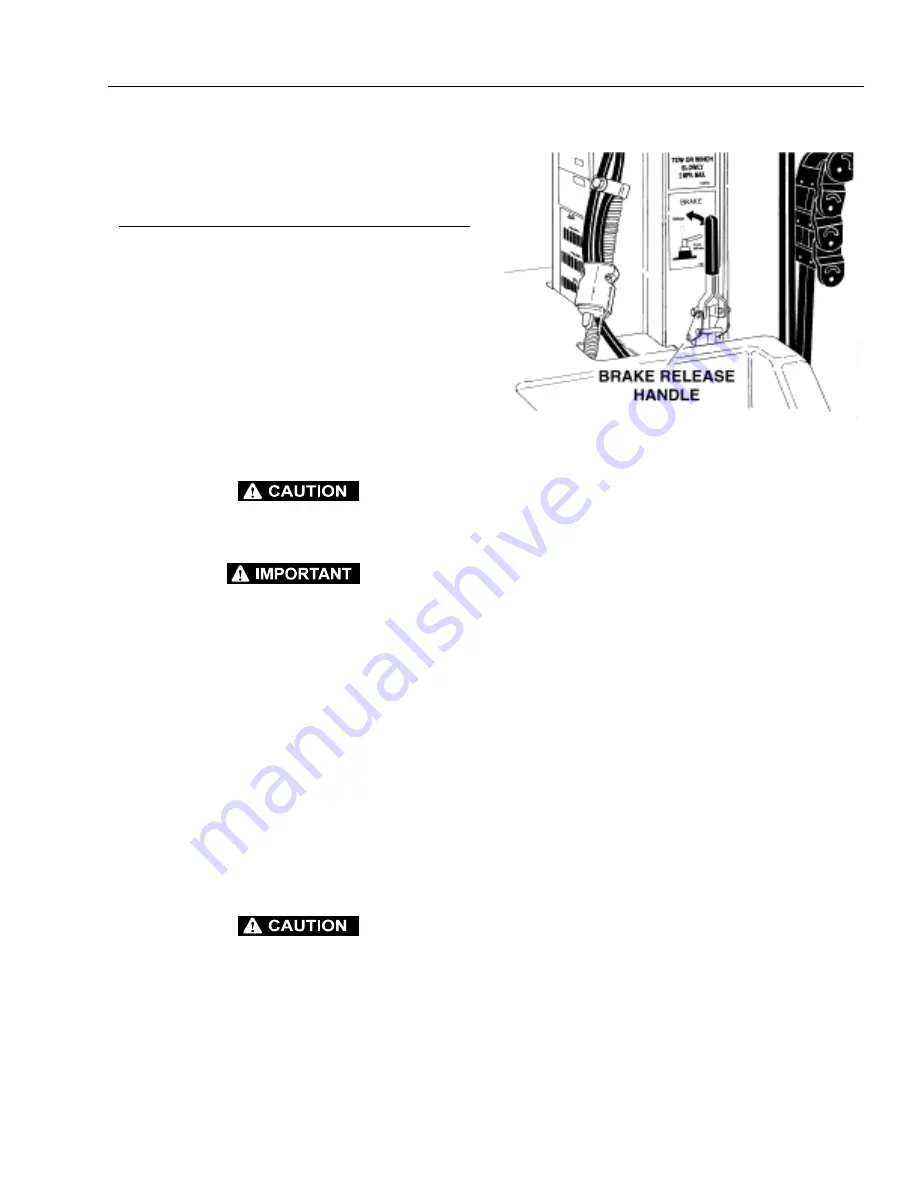

Brake Release Control

(See Figure 3-4.)

Standard equipment on all VP Series lifts is a braking sys-

tem integrated into the electric motor drive system. The

braking system is spring engaged and released electri-

cally while the machine is being driven with the joystick

controller. When the lift is at rest or the power is turned off,

the brakes are automatically engaged.

If the lift must be moved around manually as a result of

the batteries become depleted and the machine needs to

be moved from an aisleway, or machine is being winched

onto a roll-back truck bed, etc. To release the brakes, a

brake release control has been provided to engage/disen-

gage the brake system.

FOLLOW ALL APPLICABLE SAFETY PRECAUTIONS WHEN MAN-

UALLY MOVING MACHINE AROUND

(SEE SECTION 1-3)

.

WHEN PUSHED OR PUL LED MANUAL LY, THE MACHINE‘S

BRAKES MUST BE DISENGAGED AND THE EMERGENCY STOP

BUTTON SET TO THE OFF POSITION,

(DEPRESSED)

. DO NOT

ATTEMPT TO TOW OR WINCH THE MACHINE AT A SPEED

GREATER THAN (2) MPH, OR DAMAGE COULD OCCUR TO THE

MACHINE‘S ELECTRONIC CONTROLLER BOX. (DUE TO HIGH

VOLTAGE BEING GENERATED BY THE DRIVE MOTORS FEEDING

BACK INTO THE CONTROLLER BOX).

The brake release control lever is located on the right side

of the mast

(bubble level side)

. To disengage or engage

the brakes, check the brake decal located just above the

handle assembly to see which direction the handle needs

to be pointed, (the brakes are ENGAGED

(normal driving

position)

when the handle is in the up

(vertical)

position,

and DISENGAGED

(machine can be moved manually

when the handle is pulled down in a horizontal position)

.

When brakes are disengaged the machine can then be

moved around manually.

AFTER THE MACHINE HAS BEEN MANUALLY MOVED AND

BEFORE DRIVING MACHINE, ALWAYS RE-ENGAGE THE BRAKE

SYSTEM.

Figure 3-4. Brake Release Handle.

Summary of Contents for 10VP

Page 2: ...JLG Lift...

Page 4: ...This page intentionally left blank...

Page 8: ...EFFECTIVITY PAGE d JLG Lift 3120727 This page intentionally left blank...

Page 22: ...SECTION 2 PREPARATION AND INSPECTION 2 8 JLG Lift 3120727 Figure 2 6 Torque Chart...

Page 44: ...SECTION 5 OPTIONAL EQUIPMENT 5 4 JLG Lift 3120727 This page intentionally left blank...

Page 50: ......

Page 51: ......