SECTION 6 - MAST COMPONENTS

6-18

– JLG Lift –

3121222

Cylinder #2 and #3 Assembly to Cylinder #1

1.

Replace the o-rings in the cylinder joint and rod

attach cap. Lubricate the o-rings with hydraulic

oil, however keep any oil off of the threads in the

rod attach cap.

NOTE:

The attach cap threads need to be clean and free of

oil when assembled to the cylinder rod, so the loctite

applied to the cylinder rod threads will set properly.

2.

Lay cylinder #1 assembly and cylinder #2/3

assembly on the workbench in their approxi-

mate assembled position.

3.

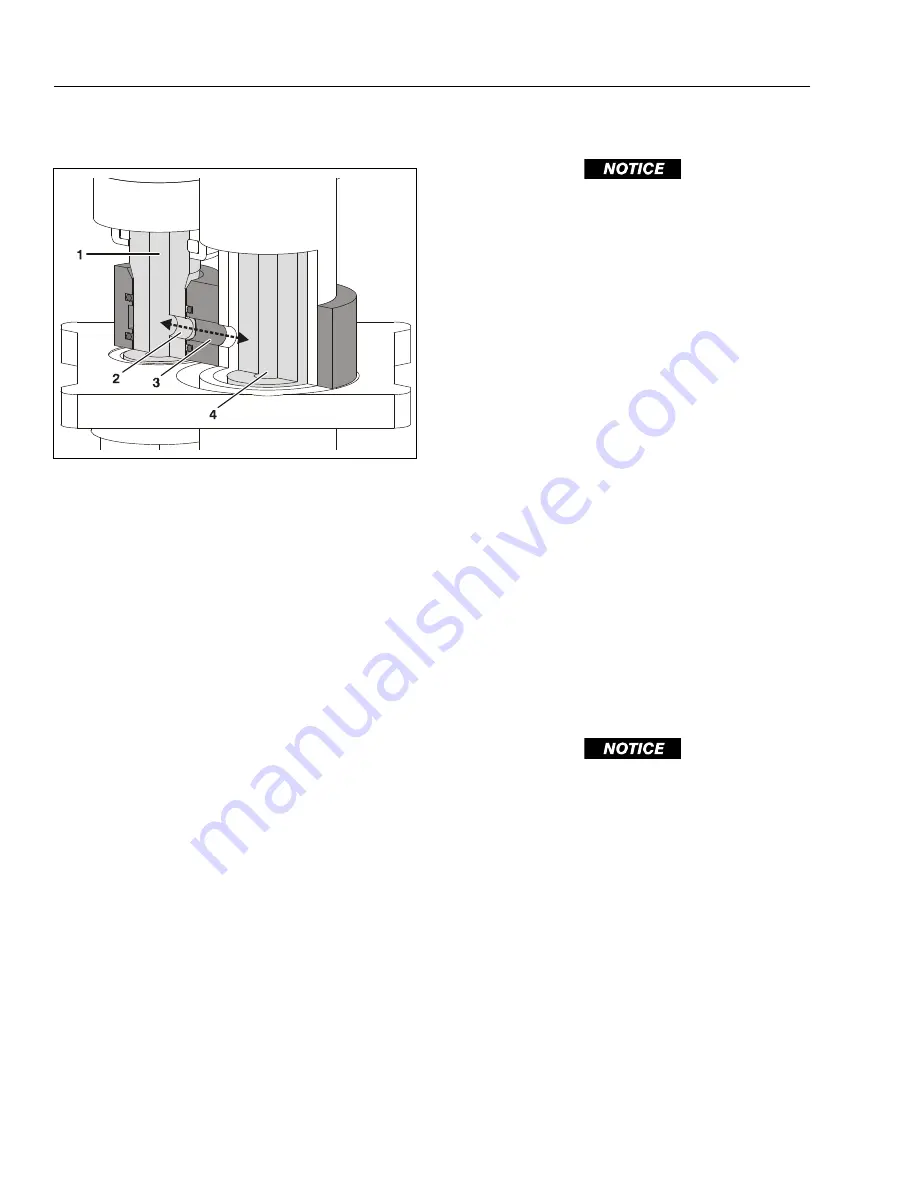

At the bottom end of the cylinder #2/3 assembly,

locate the hole on the side of the tapered cylin-

der rod end on cylinder #2. This hole should be

closely aligned with the hole passage inside the

cylinder joint of cylinder #1 assembly when

assembled.

4.

Just before final assembly apply Loctite #242 to

the threads on the tapered end of the cylinder

rod of the cylinder #2/3 assembly. Slide the cylin-

der #2/3 assembly tapered cylinder rod end into

the cylinder joint attached to cylinder #1 align-

ing the hole in the tapered cylinder rod end to

the hole in the cylinder joint.

5.

Install the rod attach cap to the tapered end of

the cylinder rod and torque the cap to 200 Nm

(45 ft. lb.).

Valve Body Installation

PROTECT THE CYLINDER ROD SURFACE. DAMAGE TO THE CYLINDER

ROD CHROME FINISH DUE TO SCRATCHING, INDENTATION, CHIPPING

OR OTHERWISE WILL CAUSE EVENTUAL GLAND SEAL FAILURE. THE

CYLINDER ROD MUST BE REPLACED IF DAMAGED.

1.

Lubricate and place a new o-ring in the groove

on the tapered end of cylinder rod #1.

NOTE:

The cylinder rod and valve body threads need to be

clean and free of oil when the valve body is assem-

bled to the cylinder assembly, so the loctite applied

to the cylinder rod threads will set properly.

2.

Clean the threads of the tapered end of the cyl-

inder rod of cylinder #1 and apply Loctite #242

to the threads.

3.

Apply a light film of hydraulic oil to the rod sur-

face above the threaded area to lubricate the o-

ring when installing the valve body to the cylin-

der rod end.

4.

Be certain the threads inside the valve body are

clean and dry of any debris or oil.

5.

Using the proper fixture to keep the cylinder rod

from turning and protect the cylinder rod from

damage, insert the valve body onto the end of

the cylinder rod and tighten, then torque to 200

Nm (45 ft. lb.).

Hydraulic Cylinder Assembly Testing

If a hydraulic cylinder testing fixture is not available to

fully pressurize the cylinder, then the cylinder must be

checked for proper operation and leaks after installation

of the mast assembly to the machine.

IF A TEST FIXTURE IS USED TO TEST THE HYDRAULIC CYLINDER, DO

NOT EXCEED THE MAXIMUM RATED PRESSURE SETTING OF THE

HYDRAULIC SYSTEM. (SEE SECTION-1 SPECIFICATIONS FOR MAXIMUM

HYDRAULIC SYSTEM PRESSURE SETTINGS.)

Figure 6-21. Cyl. #2/3 to Cylinder Joint Assembly

1.

Cyl. #2 - Cylinder Rod

2.

Cyl. #2 - Hole in Rod

3.

Passage Hole in Joint

4.

Cyl. #1 - Cylinder Rod

Summary of Contents for 1230ES

Page 1: ...AS NZS Service and Maintenance Manual Model s 1230ES P N 3121222 June 22 2017 ...

Page 2: ...NOTES ...

Page 24: ...SECTION 1 MACHINE SPECIFICATIONS 1 12 JLG Lift 3121222 NOTES ...

Page 32: ...SECTION 2 GENERAL SERVICE INFORMATION 2 8 JLG Lift 3121222 NOTES ...

Page 78: ...SECTION 4 BASE COMPONENTS 4 40 JLG Lift 3121222 NOTES ...

Page 104: ...SECTION 5 CONTROL COMPONENTS 5 26 JLG Lift 3121222 NOTES ...

Page 158: ...SECTION 8 DIAGNOSTIC TROUBLE CODES 8 22 JLG Lift 3121222 NOTES ...

Page 198: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 40 JLG Lift 3121222 ...

Page 199: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 3121222 JLG Lift 9 41 ...

Page 200: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 42 JLG Lift 3121222 ...

Page 202: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 44 JLG Lift 3121222 NOTES ...