SECTION 5 - CONTROL COMPONENTS

5-8

– JLG Lift –

3121222

5.4

POWER MODULE - P/N-1600346

1230ES Scissors built starting in mid year 2010 replaced the Sev-

con Power Module (P/N-1600473) with the ZAPI Power Module (P/

N-1001092456).

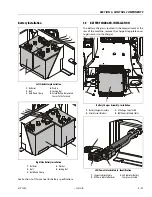

The Sevcon Power Module is located at the front-left side

of the machine inside the compartment as shown in

below. Use the following instructions when remov-

ing and installing the power module.

Removal

1.

Turn off power machine power and disconnect

the batteries.

NOTE:

Note the wire terminal locations when removing the

Power Module (See Figure 5-1.).

2.

Disconnect all wires from the power module and

remove the module mounting bolts, remove

module from the machine.

Installation

1.

Be sure that the terminals are oriented as shown.

2.

After installing the power module, begin con-

necting the wires back to the controller. (Refer-

ence Figure 5-1.)

do not overtighten the terminal bolts, or damage to the unit could

occur.

3.

Torque the terminal bolts to 5 ft lb. (7 Nm).

4.

After all connections to the power module are

made, the battery can be reconnected.

Power Module Electrical Evaluation

Several basic electrical tests can be performed on the

Power Module. Failure of one of these evaluations is signif-

icant and may indicate that the device is physically dam-

aged. If a Power Module is suspected to be faulty,

thoroughly examine the rest of the system for possible

damage.

Make all measurements with a voltmeter set to resistance

scale (Ohms) (Refer to Section 9 - Figure 9-2., Resistance

Measurement). Disconnect the Main Battery Disconnect

and all cables from the Power Module during this analysis.

Wait 60 seconds after power is disconnected to allow

internal charge to dissipate (risk of hazard, improper read-

ings otherwise).

Figure 5-3. Power Module - Installation

1.

Power Module

2.

Mounting Screws

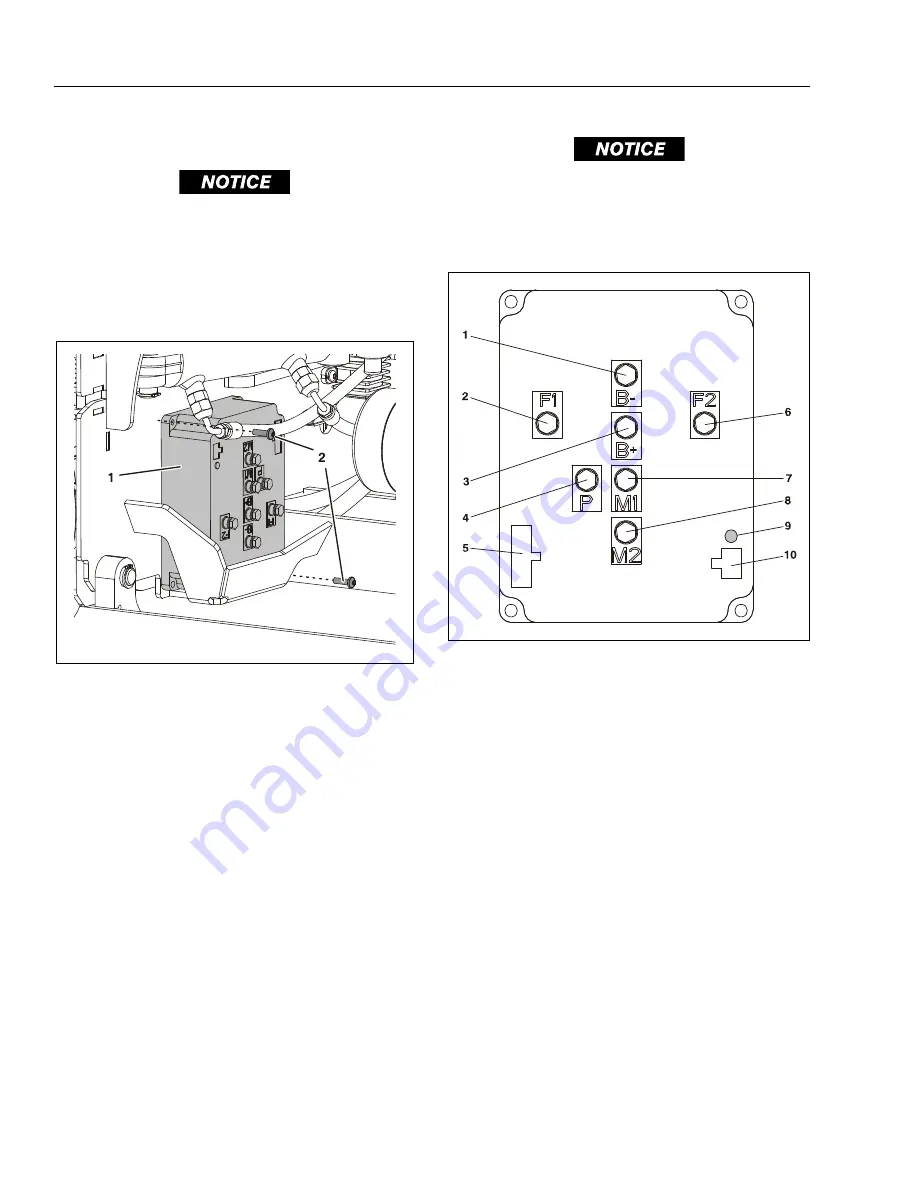

Figure 5-4. Sevcon Power Module Terminals

1.

B – (battery (–) terminal)

2.

F1 (motor field terminal)

3.

B+ (battery (+) terminal)

4.

P - (pump (–) terminal)

5.

Mini-Fit Jr/B-

Connector

6.

F2 - (motor field terminal)

7.

M1 - (motor armature terminal)

8.

M2 - (motor armature terminal)

9.

DTC Flash Code LED Indicator

10.

Unused

Summary of Contents for 1230ES

Page 1: ...AS NZS Service and Maintenance Manual Model s 1230ES P N 3121222 June 22 2017 ...

Page 2: ...NOTES ...

Page 24: ...SECTION 1 MACHINE SPECIFICATIONS 1 12 JLG Lift 3121222 NOTES ...

Page 32: ...SECTION 2 GENERAL SERVICE INFORMATION 2 8 JLG Lift 3121222 NOTES ...

Page 78: ...SECTION 4 BASE COMPONENTS 4 40 JLG Lift 3121222 NOTES ...

Page 104: ...SECTION 5 CONTROL COMPONENTS 5 26 JLG Lift 3121222 NOTES ...

Page 158: ...SECTION 8 DIAGNOSTIC TROUBLE CODES 8 22 JLG Lift 3121222 NOTES ...

Page 198: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 40 JLG Lift 3121222 ...

Page 199: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 3121222 JLG Lift 9 41 ...

Page 200: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 42 JLG Lift 3121222 ...

Page 202: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 44 JLG Lift 3121222 NOTES ...