SECTION 4 - BASE COMPONENTS

3121222

– JLG Lift –

4-11

4.8

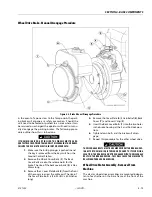

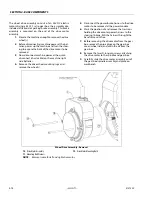

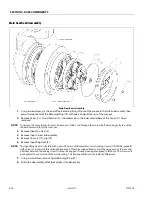

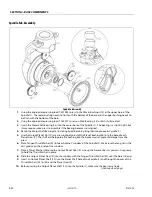

WHEEL DRIVE ASSEMBLY - SERVICING

The component parts of the left and right drive motor

assemblies are identical. The left drive motor is run in the

reverse direction of the right motor.

for details on the traction system electrical theory of operation

see section 4.

Drive Motor Electrical Evaluation

Several basic electrical tests can be performed on the

Drive Motors. Failure of one of these evaluations is signifi-

cant and may indicate that the device is physically dam-

aged.

Make all measurements with a voltmeter set to resistance

scale (Ohms). Disconnect the Main Battery Disconnect

and all drive motor cables during this analysis.

1. Resistance < 2 Ohms Red to Black Armature

Wires.

The heavy red and black conductors are con-

nected to the motor's armature winding. The

winding is a very low impedance and should

appear to be a short-circuit for an ordinary volt-

meter (other tests can determine if the armature

is truly shorted). High resistance can signal cor-

rosion, improper crimps, damaged cabling, worn

brushes, a faulty commutator, or an open arma-

ture winding.

2. Resistance < 2 Ohms Blue to Orange Field

Wires.

The blue and orange conductors are connected

to the motor's field winding. In order to make

this measurement, it will be necessary to discon-

nect the butt-splice on the two orange wires or

use a piercing meter probe. As with the arma-

ture, the field is a very low impedance and

should appear to be a short-circuit for an ordi-

nary voltmeter. High resistance can signal corro-

sion, improper crimps, damaged connectors,

damaged cabling, or an open field winding.

3. Resistance 15-25 Ohms Yellow to Brown

Brake Wires.

The yellow and brown wires are connected to

the integral brake. Improper resistance can sig-

nal corrosion, improper crimps, damaged

cabling, or a fault solenoid.

4. Resistance > 1 mOhm Red Armature Wire to

Motor Housing.

The armature winding should be electrically iso-

lated from the motor housing. Low resistance

may be an indication of a crushed cable, a

burned cable, or a burned armature winding.

Investigate by disconnecting the drive motor

cable from the motor and re-measure resistance

(isolation).

5. Resistance > 1 mOhm Blue Field Wire to

Motor Housing.

The field winding should also be electrically iso-

lated from the motor housing. Low resistance

may be an indication of a crushed cable, a

burned cable, or a burned field winding. Investi-

gate by disconnecting the drive motor cable

from the motor and re-measure resistance (isola-

tion).

6. Resistance > 1 mOhm Red Armature Wire to

Blue Field Wire.

The armature and field windings should also be

electrically isolated from one another. Low resis-

tance may be an indication of a crushed cable, a

burned cable, damaged windings. Investigate

by disconnecting the drive motor cable from the

motor and re-measure resistance (isolation).

Summary of Contents for 1230ES

Page 1: ...AS NZS Service and Maintenance Manual Model s 1230ES P N 3121222 June 22 2017 ...

Page 2: ...NOTES ...

Page 24: ...SECTION 1 MACHINE SPECIFICATIONS 1 12 JLG Lift 3121222 NOTES ...

Page 32: ...SECTION 2 GENERAL SERVICE INFORMATION 2 8 JLG Lift 3121222 NOTES ...

Page 78: ...SECTION 4 BASE COMPONENTS 4 40 JLG Lift 3121222 NOTES ...

Page 104: ...SECTION 5 CONTROL COMPONENTS 5 26 JLG Lift 3121222 NOTES ...

Page 158: ...SECTION 8 DIAGNOSTIC TROUBLE CODES 8 22 JLG Lift 3121222 NOTES ...

Page 198: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 40 JLG Lift 3121222 ...

Page 199: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 3121222 JLG Lift 9 41 ...

Page 200: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 42 JLG Lift 3121222 ...

Page 202: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 44 JLG Lift 3121222 NOTES ...