SECTION 3 - CHASSIS & TURNTABLE

3121619

3-69

376

281

630

12

Internal hardware monitoring: the ECU finds

an error during the access to its EEPROM

memory or works with an alternative value

Section could not be erased

Threshold for error detection is an internal ECU

threshold.

There is no healing possible for the error. In the

every new initialization phase, the

debounce level is set to zero.

If not programmed, EEPROM is defect --> ECU is

defect, reprogramm ECU and if

necessary replace it.

377

281

630

12

Internal hardware monitoring: the ECU finds

an error during the access to its EEPROM

memory or works with an alternative value

Minimum 3 blocks could not be readed,

EEPROM has Checksum Error

There is no healing possible for the error. In the

every new initialization phase, the

debounce level is set to zero.

If not programmed, EEPROM is defect -->ECU is

defect, reprogramm ECU and if

necessary replace it

378

281

630

12

Internal hardware monitoring: the ECU finds

an error during the access to it's EEPROM

memory or works with an alternative value

Block could not be written for minimum 3 times Threshold for error detection is an internal ECU

threshold.

If not programmed, EEPROM is defect --> ECU is

defect, reprogramm ECU and if

necessary replace it.

381

693

411

4

Range check cannot be done or interrupted.

EGR or wiring defect

Check wiring harness and connected EGR.

387

555

523612

12

Internal hardware monitoring: the CPU of

the ECU is reset and the cause is logged inter-

nally; no item will be created in error mem-

ory

Injector shut off demand for the ICO coordinator

System responses:

not

Threshold for error detection is an internal ECU

threshold.

Caution ! Sequence error, check error memory

for other errors.

389

214

190

0

Engine speed: the engine speed calculated

by ECU is above the target range; the ECU

activates a system reaction

Overspeed monitoring during 1 level of FOC

(Failure overrun condition) if engine speed

was over Limit.

check powertrain settings regarding overspeed

390

214

190

11

Engine speed: the engine speed calculated

by ECU is above the target range; the ECU

activates a system reaction

Overspeed monitoring during 2 level of FOC

(Failure overrun condition) if engine speed

was over limit.

check powertrain settings regarding overspeed

391

214

190

14

Engine speed: the engine speed calculated

by ECU is above the target range; the ECU

activates a system reaction

Overspeed monitoring during ORC (Override

conditions) if engine speed was over

2900rpm

check powertrain settings regarding overspeed

417

312

171

3

Sensor error SCR-System environment tem-

perature; DPF-System air inlet temperature;

signal range check high

open loop to sensor

Check cabling, if environment temperature sen-

sor is not working, check sensor

and if necessary replace it, check connection

cable and if necessary repair or replace it.

418

312

171

4

Sensor error SCR-System environment tem-

perature; DPF-System air inlet temperature;

signal range check low

short circuit to Ground

Check cabling, if environment temperature sen-

sor is not working, check sensor

and if necessary replace it, check connection

cable and if necessary repair or replace it

419

212

190

8

Camshaft speed sensor: the ECU receives no

signal and uses the signal from crankshaft

speed sensor as alternative to calculate the

engine speed

When disturbed camshaft signal detected.

Error in sensor or wiring.

Threshold for error detection is an internal ECU

threshold, occurs by disturbed

camshaft signal.

Check increment wheel position, clean and

adjust if necessary, check sensor postition.

Check Camshaft Sensor or wiring.

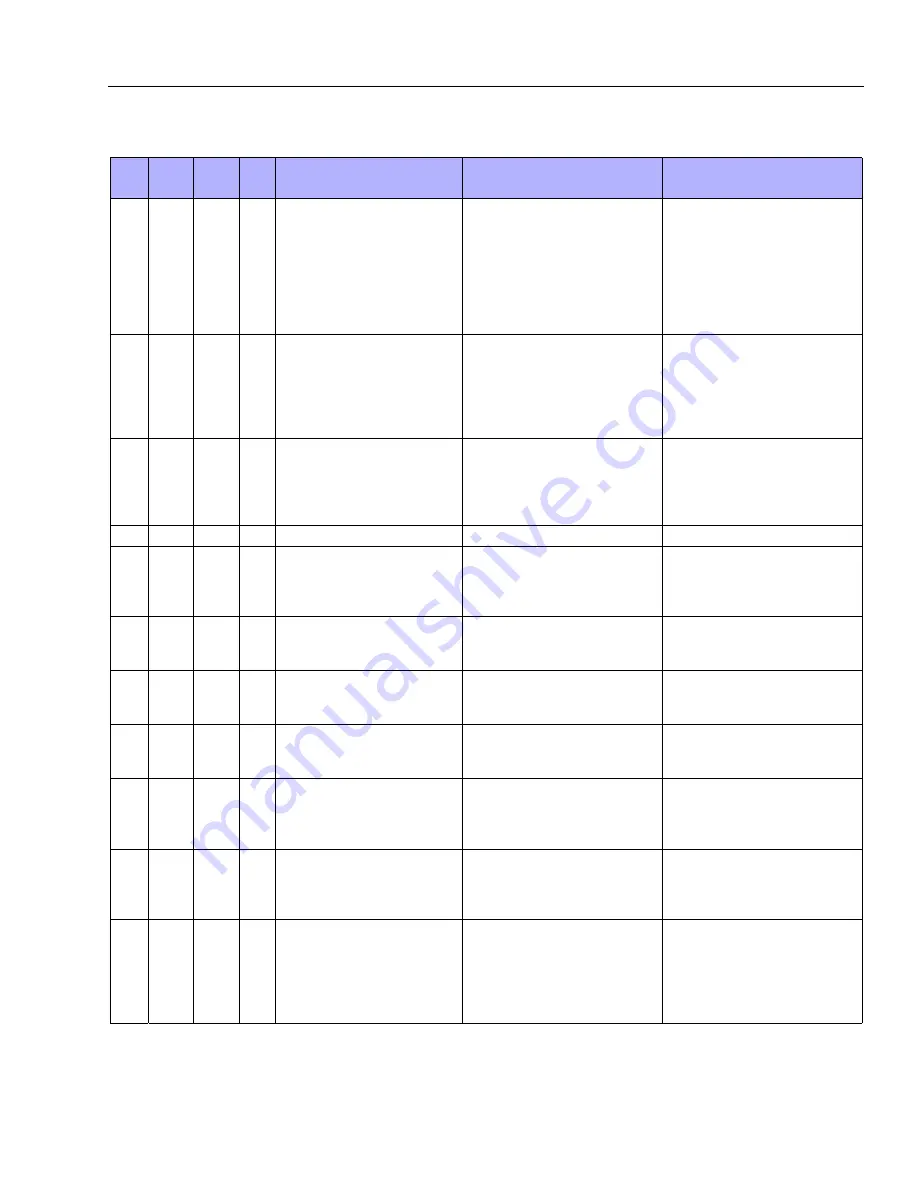

Table 3-10. Engine Fault Codes

Deutz

Code

Blink

Code

SPN

FMI

Description

Possible Cause

Action

Summary of Contents for 1850SJ

Page 1: ...Service and Maintenance Manual Model 1850SJ 3121619 June 29 2018 Rev J AS NZS...

Page 2: ......

Page 21: ...3121619 xvii LIST OF FIGURES FIGURE NO TITLE PAGE NO Thispageleftblankintentionally...

Page 24: ...xx 3121619 LIST OF TABLES TABLE NO TITLE PAGE NO Thispageleftblankintentionally...

Page 50: ...SECTION 2 GENERAL 2 12 3121619 NOTES...

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 5 This page left blank intentionally...

Page 56: ...SECTION 3 CHASSIS TURNTABLE 3 6 3121619 Figure 3 4 Axle Hose Routing Sheet 1 of 2...

Page 57: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 7 Figure 3 5 Axle Hose Routing Sheet 2 of 2...

Page 58: ...SECTION 3 CHASSIS TURNTABLE 3 8 3121619 Figure 3 6 Steering Axle Hydraulic Circuit...

Page 61: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 11 Figure 3 9 Turntable Hydraulic System...

Page 92: ...SECTION 3 CHASSIS TURNTABLE 3 42 3121619 Figure 3 39 Swing Bearing Wear Tolerance...

Page 94: ...SECTION 3 CHASSIS TURNTABLE 3 44 3121619 Figure 3 41 Swing Bearing Removal Sheet 2 of 4...

Page 110: ...SECTION 3 CHASSIS TURNTABLE 3 60 3121619 Figure 3 54 Engine Electrical Circuit...

Page 169: ...SECTION 4 BOOM PLATFORM 3121619 4 7 Figure 4 1 Boom Hydraulic System...

Page 173: ...SECTION 4 BOOM PLATFORM 3121619 4 11 Figure 4 2 Boom Assembly Sheet 1 of 9...

Page 174: ...SECTION 4 BOOM PLATFORM 4 12 3121619 Figure 4 3 Boom Assembly Sheet 2 of 9...

Page 175: ...SECTION 4 BOOM PLATFORM 3121619 4 13 Figure 4 4 Boom Assembly Sheet 3 of 9...

Page 176: ...SECTION 4 BOOM PLATFORM 4 14 3121619 Figure 4 5 Boom Assembly Sheet 4 of 9...

Page 177: ...SECTION 4 BOOM PLATFORM 3121619 4 15 Figure 4 6 Boom Assembly Sheet 5 of 9...

Page 178: ...SECTION 4 BOOM PLATFORM 4 16 3121619 Figure 4 7 Boom Assembly Sheet 6 of 9...

Page 179: ...SECTION 4 BOOM PLATFORM 3121619 4 17 Figure 4 8 Boom Assembly Sheet 7 of 9...

Page 180: ...SECTION 4 BOOM PLATFORM 4 18 3121619 Figure 4 9 Boom Assembly Sheet 8 of 9...

Page 181: ...SECTION 4 BOOM PLATFORM 3121619 4 19 Figure 4 10 Boom Assembly Sheet 9 of 9...

Page 187: ...SECTION 4 BOOM PLATFORM 3121619 4 25 Figure 4 16 Boom Assembly Torque Values Sheet 1 of 4...

Page 188: ...SECTION 4 BOOM PLATFORM 4 26 3121619 Figure 4 17 Boom Assembly Torque Values Sheet 2 of 4...

Page 189: ...SECTION 4 BOOM PLATFORM 3121619 4 27 Figure 4 18 Boom Assembly Torque Values Sheet 3 of 4...

Page 190: ...SECTION 4 BOOM PLATFORM 4 28 3121619 Figure 4 19 Boom Assembly Torque Values Sheet 4 of 4...

Page 201: ...SECTION 4 BOOM PLATFORM 3121619 4 39 Figure 4 20 Hose Adjustment...

Page 202: ...SECTION 4 BOOM PLATFORM 4 40 3121619 Figure 4 21 Section 3 Boom Cables...

Page 203: ...SECTION 4 BOOM PLATFORM 3121619 4 41 Figure 4 22 Section 4 Boom Cables...

Page 204: ...SECTION 4 BOOM PLATFORM 4 42 3121619 Figure 4 23 Section 5 Boom Cables...

Page 205: ...SECTION 4 BOOM PLATFORM 3121619 4 43 Figure 4 24 Jib Hydraulics Sheet 1 of 7...

Page 234: ...SECTION 4 BOOM PLATFORM 4 72 3121619 Figure 4 44 Powertrack Shimming Instructions...

Page 239: ...SECTION 4 BOOM PLATFORM 3121619 4 77 Figure 4 49 Powertrack Hose Installation Sheet 1 of 4...

Page 240: ...SECTION 4 BOOM PLATFORM 4 78 3121619 Figure 4 50 Powertrack Hose Installation Sheet 2 of 4...

Page 241: ...SECTION 4 BOOM PLATFORM 3121619 4 79 Figure 4 51 Powertrack Hose Installation Sheet 3 of 4...

Page 242: ...SECTION 4 BOOM PLATFORM 4 80 3121619 Figure 4 52 Powertrack Hose Installation Sheet 4 of 4...

Page 252: ...SECTION 4 BOOM PLATFORM 4 90 3121619 NOTES...

Page 432: ...SECTION 5 BASIC HYDRAULIC INFORMATION HYDRAULIC SCHEMATICS 5 180 3121619 NOTES...

Page 527: ...SECTION 6 JLG CONTROL SYSTEM 3121619 6 95 Figure 6 36 LSS Installation Sheet 1 of 4...

Page 528: ...SECTION 6 JLG CONTROL SYSTEM 6 96 3121619 Figure 6 37 LSS Installation Sheet 2 of 4...

Page 529: ...SECTION 6 JLG CONTROL SYSTEM 3121619 6 97 Figure 6 38 LSS Installation Sheet 3 of 4...

Page 530: ...SECTION 6 JLG CONTROL SYSTEM 6 98 3121619 Figure 6 39 LSS Installation Sheet 4 of 4...

Page 710: ...SECTION 7 BASIC ELECTRICAL INFORMATION ELECTRICAL SCHEMATICS 7 118 3121619 NOTES...

Page 711: ......