SECTION 6 - JLG CONTROL SYSTEM

3121619

6-75

6.10 BOOM UNLOCK PROCEDURE

If the fault “LIFT CYLINDER OVER PRESSURE” or “WRONG TELE

RESPONSE” is active, then the boom will be trapped in trans-

port.

To clear these faults, the Boom Unlock Procedure must be fol-

lowed.

Initial Conditions

Before performing the Boom Unlock Procedure, the following

conditions must be met:

• Booms Sensors, Jib Sensors, Axle Sensor and tilt sensor cal-

ibrations must be successfully completed

• The Boom is operating in the BCS Normal Mode

• The parking brake is not reporting a short to battery from

the UGM or the UCM

• The main boom sensor is reading less than 600”

• The jib is fully retracted

• The main boom sensor is reading less than 7 degrees

• The axles are completely extended

• The machine control system indicates that it is not tilted

• The turntable is centered between the rear tires

• Ground Mode is selected

Procedure

NOTE:

During the calibration, if the ESC key is pressed after the

procedure is started, the calibration will be aborted and

exit back to the “UNLOCK BOOM” prompt.

NOTE:

The envelope, moment and appropriate faults will continu-

ously be monitored after the initial conditions are satisfied.

If at any time during the test these conditions change to an

unsafe state (communications lost, envelope violation,

moment violation etc.) the Calibration will abort and the

analyzer will display “ENVLP VIOLATION”.

1.

Using the analyzer, enter access level 1. Unlock Boom

can be found under the Calibrations menu.

2.

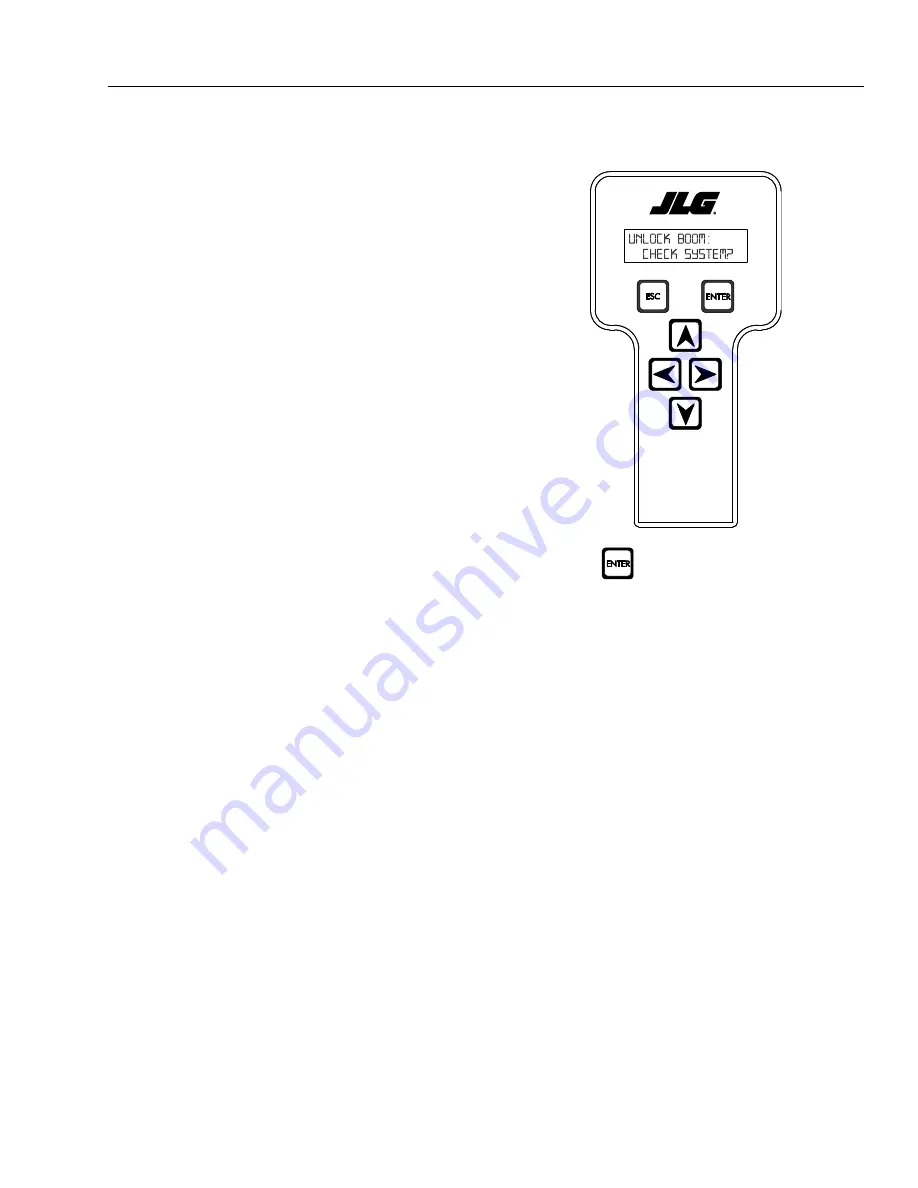

Once the operator selects the UNLOCK BOOM option,

the screen will read:

Pressing

will cause the boom to check the initial

conditions listed above. If any of the calibrations have

not been completed “CAL. BOOM” will be displayed. If

there is a problem with the envelope, moment or any of

the supporting sensors (including loss of communica-

tions) “CHECK FAULTS” will be displayed. If the parking

brake is shorted anywhere in the system “PARK BRAKE

FAULT” will be displayed. If the jib is not fully retracted

“JIB TELE IN” will be displayed. If the telescope is reading

more than 600”, “MAIN TELE IN” will be displayed. If the

main boom angle sensors are reading more than 7

degrees, “MAIN LIFT DOWN” will be displayed, if the

axles are not extended “EXTEND AXLES” will be dis-

played. If the DOS switch is not indicating in line and the

angles are not within 10° of inline “ALIGN TURNTABLE”

will be displayed. If the chassis tilt is tilted “LEVEL

MACHINE” will be displayed. If the machine is in plat-

form mode. “SELECT GRND MODE” will be displayed. If

none of the above faults are present, the test will move

on to the next step. As each fault is cleared, the system

will make sure no other faults are active. During this

time the latched faults from If the fault “LIFT CYLINDER

OVER PRESSURE” or “WRONG TELE RESPONSE” is active,

then the boom will be trapped in transport. These faults

will be latched through key-cycle.

Summary of Contents for 1850SJ

Page 1: ...Service and Maintenance Manual Model 1850SJ 3121619 June 29 2018 Rev J AS NZS...

Page 2: ......

Page 21: ...3121619 xvii LIST OF FIGURES FIGURE NO TITLE PAGE NO Thispageleftblankintentionally...

Page 24: ...xx 3121619 LIST OF TABLES TABLE NO TITLE PAGE NO Thispageleftblankintentionally...

Page 50: ...SECTION 2 GENERAL 2 12 3121619 NOTES...

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 5 This page left blank intentionally...

Page 56: ...SECTION 3 CHASSIS TURNTABLE 3 6 3121619 Figure 3 4 Axle Hose Routing Sheet 1 of 2...

Page 57: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 7 Figure 3 5 Axle Hose Routing Sheet 2 of 2...

Page 58: ...SECTION 3 CHASSIS TURNTABLE 3 8 3121619 Figure 3 6 Steering Axle Hydraulic Circuit...

Page 61: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 11 Figure 3 9 Turntable Hydraulic System...

Page 92: ...SECTION 3 CHASSIS TURNTABLE 3 42 3121619 Figure 3 39 Swing Bearing Wear Tolerance...

Page 94: ...SECTION 3 CHASSIS TURNTABLE 3 44 3121619 Figure 3 41 Swing Bearing Removal Sheet 2 of 4...

Page 110: ...SECTION 3 CHASSIS TURNTABLE 3 60 3121619 Figure 3 54 Engine Electrical Circuit...

Page 169: ...SECTION 4 BOOM PLATFORM 3121619 4 7 Figure 4 1 Boom Hydraulic System...

Page 173: ...SECTION 4 BOOM PLATFORM 3121619 4 11 Figure 4 2 Boom Assembly Sheet 1 of 9...

Page 174: ...SECTION 4 BOOM PLATFORM 4 12 3121619 Figure 4 3 Boom Assembly Sheet 2 of 9...

Page 175: ...SECTION 4 BOOM PLATFORM 3121619 4 13 Figure 4 4 Boom Assembly Sheet 3 of 9...

Page 176: ...SECTION 4 BOOM PLATFORM 4 14 3121619 Figure 4 5 Boom Assembly Sheet 4 of 9...

Page 177: ...SECTION 4 BOOM PLATFORM 3121619 4 15 Figure 4 6 Boom Assembly Sheet 5 of 9...

Page 178: ...SECTION 4 BOOM PLATFORM 4 16 3121619 Figure 4 7 Boom Assembly Sheet 6 of 9...

Page 179: ...SECTION 4 BOOM PLATFORM 3121619 4 17 Figure 4 8 Boom Assembly Sheet 7 of 9...

Page 180: ...SECTION 4 BOOM PLATFORM 4 18 3121619 Figure 4 9 Boom Assembly Sheet 8 of 9...

Page 181: ...SECTION 4 BOOM PLATFORM 3121619 4 19 Figure 4 10 Boom Assembly Sheet 9 of 9...

Page 187: ...SECTION 4 BOOM PLATFORM 3121619 4 25 Figure 4 16 Boom Assembly Torque Values Sheet 1 of 4...

Page 188: ...SECTION 4 BOOM PLATFORM 4 26 3121619 Figure 4 17 Boom Assembly Torque Values Sheet 2 of 4...

Page 189: ...SECTION 4 BOOM PLATFORM 3121619 4 27 Figure 4 18 Boom Assembly Torque Values Sheet 3 of 4...

Page 190: ...SECTION 4 BOOM PLATFORM 4 28 3121619 Figure 4 19 Boom Assembly Torque Values Sheet 4 of 4...

Page 201: ...SECTION 4 BOOM PLATFORM 3121619 4 39 Figure 4 20 Hose Adjustment...

Page 202: ...SECTION 4 BOOM PLATFORM 4 40 3121619 Figure 4 21 Section 3 Boom Cables...

Page 203: ...SECTION 4 BOOM PLATFORM 3121619 4 41 Figure 4 22 Section 4 Boom Cables...

Page 204: ...SECTION 4 BOOM PLATFORM 4 42 3121619 Figure 4 23 Section 5 Boom Cables...

Page 205: ...SECTION 4 BOOM PLATFORM 3121619 4 43 Figure 4 24 Jib Hydraulics Sheet 1 of 7...

Page 234: ...SECTION 4 BOOM PLATFORM 4 72 3121619 Figure 4 44 Powertrack Shimming Instructions...

Page 239: ...SECTION 4 BOOM PLATFORM 3121619 4 77 Figure 4 49 Powertrack Hose Installation Sheet 1 of 4...

Page 240: ...SECTION 4 BOOM PLATFORM 4 78 3121619 Figure 4 50 Powertrack Hose Installation Sheet 2 of 4...

Page 241: ...SECTION 4 BOOM PLATFORM 3121619 4 79 Figure 4 51 Powertrack Hose Installation Sheet 3 of 4...

Page 242: ...SECTION 4 BOOM PLATFORM 4 80 3121619 Figure 4 52 Powertrack Hose Installation Sheet 4 of 4...

Page 252: ...SECTION 4 BOOM PLATFORM 4 90 3121619 NOTES...

Page 432: ...SECTION 5 BASIC HYDRAULIC INFORMATION HYDRAULIC SCHEMATICS 5 180 3121619 NOTES...

Page 527: ...SECTION 6 JLG CONTROL SYSTEM 3121619 6 95 Figure 6 36 LSS Installation Sheet 1 of 4...

Page 528: ...SECTION 6 JLG CONTROL SYSTEM 6 96 3121619 Figure 6 37 LSS Installation Sheet 2 of 4...

Page 529: ...SECTION 6 JLG CONTROL SYSTEM 3121619 6 97 Figure 6 38 LSS Installation Sheet 3 of 4...

Page 530: ...SECTION 6 JLG CONTROL SYSTEM 6 98 3121619 Figure 6 39 LSS Installation Sheet 4 of 4...

Page 710: ...SECTION 7 BASIC ELECTRICAL INFORMATION ELECTRICAL SCHEMATICS 7 118 3121619 NOTES...

Page 711: ......