SECTION 3 - CHASSIS & TURNTABLE

3-30

3121619

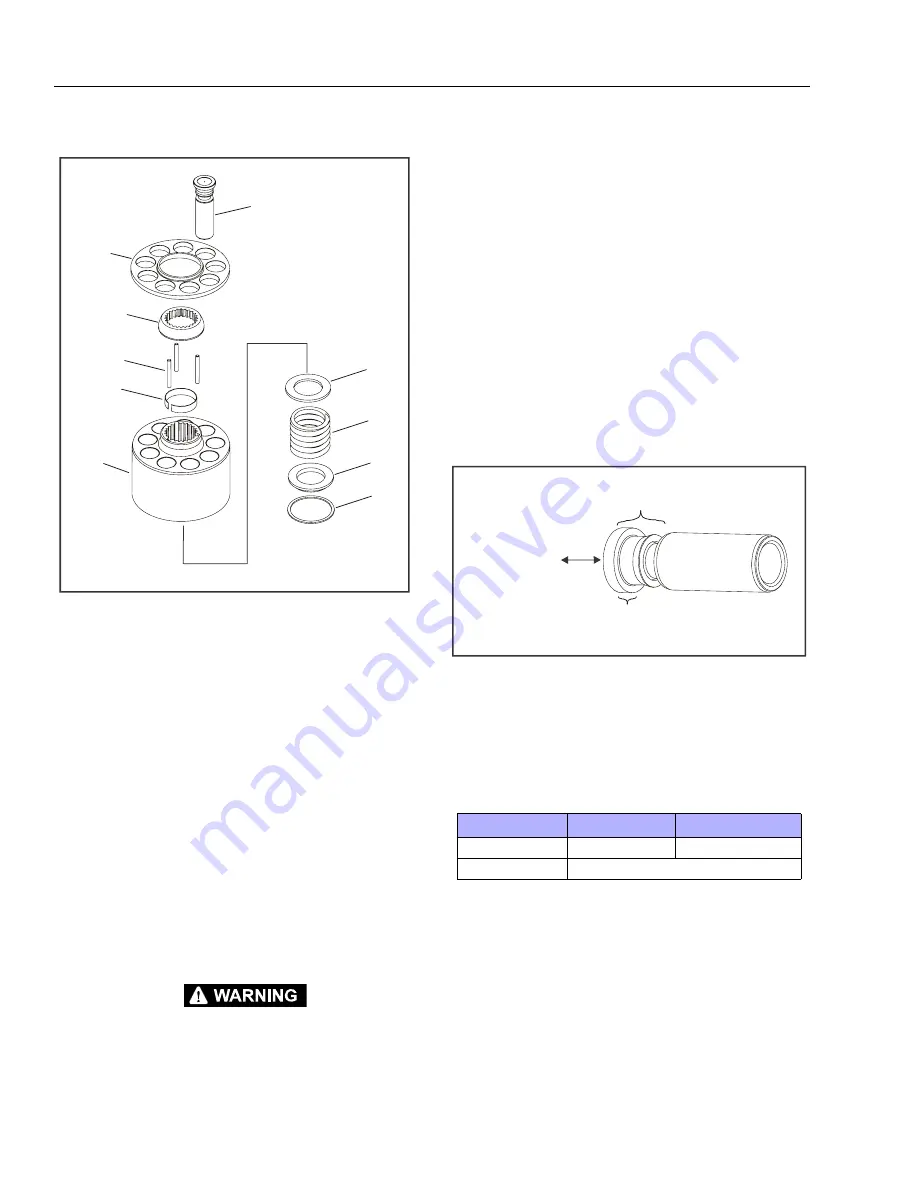

Figure 3-26. Cylinder Kit Disassembly

25.

Remove pistons (44) and slipper retainer (45) from cylin-

der block (46).

NOTE:

Pistons are not selectively fitted. However, units with high

hourly usage may develop wear patterns. Number pistons

and bores for reassembly if they are to be reused.

26.

Remove ball guide (47), hold-down pins (48), and retain-

ing ring (49) from cylinder block.

NOTE:

Most repairs do not require block spring removal. Perform

this procedure only if you suspect problems with the block

spring.

RISK OF PERSONAL INJURY: COMPRESSING THE BLOCK SPRING REQUIRES

FORCE OF ABOUT 80 TO 90 LBF (350 TO 400 N). USE A PRESS SUFFICIENT TO

MAINTAIN THIS FORCE WITH REASONABLE EFFORT. ENSURE THE SPRING IS

SECURE BEFORE ATTEMPTING TO REMOVE THE SPIRAL RETAINING RING.

RELEASE THE PRESSURE SLOWLY AFTER THE RETAINING RING IS REMOVED.

27.

Turn block over. Using a press, apply pressure on block

spring washer (50) to compress block spring. Compress

spring enough to safely remove spiral retaining ring

(51). While maintaining pressure, unwind spiral retaining

ring (51). Carefully release pressure and remove outer

block spring washer (50), block spring (52), and inner

block spring washer (53) from cylinder block.

Inspection

After disassembly, wash all parts (including end-cap and hous-

ing) thoroughly with clean solvent and allow to air dry. Blow

out oil passages in housing and endcap with compressed air.

Conduct inspection in a clean area and keep all parts free from

contamination. Clean and dry parts again after any rework or

resurfacing.

PISTON

Inspect pistons for damage and discoloration. Discolored pis-

tons may indicate excessive heat; do not reuse.

SLIPPERS

Inspect slipper running surfaces. Replace piston assemblies

with scored or excessively rounded slipper edges. Measure

slipper foot thickness. Replace piston assemblies with exces-

sively worn slippers. Check slipper axial end-play. Replace pis-

ton assemblies with excessive end-play.

44. Piston

45. Slipper Retainer

46. Cylinder Block

47. Ball Guide

48. Holddown Pins

49. Retaining Ring

50. Block Spring Washer

51. Spiral Retaining Ring

52. Block Spring

53. Inner Block Spring Washer

51

50

52

53

46

49

48

47

45

44

Table 3-6. Slipper Foot Thickness & End Play

Measurement

L Frame

K Frame

Slipper Foot Thickness

2.71 mm (0.11 in.)

4.07 mm (0.16 in.)

Piston/Slipper End Play

0.15 mm (0.006 in.)

Slipper

Maximum End Play

Minimum Slipper Foot Thickness

Summary of Contents for 1850SJ

Page 1: ...Service and Maintenance Manual Model 1850SJ 3121619 June 29 2018 Rev J AS NZS...

Page 2: ......

Page 21: ...3121619 xvii LIST OF FIGURES FIGURE NO TITLE PAGE NO Thispageleftblankintentionally...

Page 24: ...xx 3121619 LIST OF TABLES TABLE NO TITLE PAGE NO Thispageleftblankintentionally...

Page 50: ...SECTION 2 GENERAL 2 12 3121619 NOTES...

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 5 This page left blank intentionally...

Page 56: ...SECTION 3 CHASSIS TURNTABLE 3 6 3121619 Figure 3 4 Axle Hose Routing Sheet 1 of 2...

Page 57: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 7 Figure 3 5 Axle Hose Routing Sheet 2 of 2...

Page 58: ...SECTION 3 CHASSIS TURNTABLE 3 8 3121619 Figure 3 6 Steering Axle Hydraulic Circuit...

Page 61: ...SECTION 3 CHASSIS TURNTABLE 3121619 3 11 Figure 3 9 Turntable Hydraulic System...

Page 92: ...SECTION 3 CHASSIS TURNTABLE 3 42 3121619 Figure 3 39 Swing Bearing Wear Tolerance...

Page 94: ...SECTION 3 CHASSIS TURNTABLE 3 44 3121619 Figure 3 41 Swing Bearing Removal Sheet 2 of 4...

Page 110: ...SECTION 3 CHASSIS TURNTABLE 3 60 3121619 Figure 3 54 Engine Electrical Circuit...

Page 169: ...SECTION 4 BOOM PLATFORM 3121619 4 7 Figure 4 1 Boom Hydraulic System...

Page 173: ...SECTION 4 BOOM PLATFORM 3121619 4 11 Figure 4 2 Boom Assembly Sheet 1 of 9...

Page 174: ...SECTION 4 BOOM PLATFORM 4 12 3121619 Figure 4 3 Boom Assembly Sheet 2 of 9...

Page 175: ...SECTION 4 BOOM PLATFORM 3121619 4 13 Figure 4 4 Boom Assembly Sheet 3 of 9...

Page 176: ...SECTION 4 BOOM PLATFORM 4 14 3121619 Figure 4 5 Boom Assembly Sheet 4 of 9...

Page 177: ...SECTION 4 BOOM PLATFORM 3121619 4 15 Figure 4 6 Boom Assembly Sheet 5 of 9...

Page 178: ...SECTION 4 BOOM PLATFORM 4 16 3121619 Figure 4 7 Boom Assembly Sheet 6 of 9...

Page 179: ...SECTION 4 BOOM PLATFORM 3121619 4 17 Figure 4 8 Boom Assembly Sheet 7 of 9...

Page 180: ...SECTION 4 BOOM PLATFORM 4 18 3121619 Figure 4 9 Boom Assembly Sheet 8 of 9...

Page 181: ...SECTION 4 BOOM PLATFORM 3121619 4 19 Figure 4 10 Boom Assembly Sheet 9 of 9...

Page 187: ...SECTION 4 BOOM PLATFORM 3121619 4 25 Figure 4 16 Boom Assembly Torque Values Sheet 1 of 4...

Page 188: ...SECTION 4 BOOM PLATFORM 4 26 3121619 Figure 4 17 Boom Assembly Torque Values Sheet 2 of 4...

Page 189: ...SECTION 4 BOOM PLATFORM 3121619 4 27 Figure 4 18 Boom Assembly Torque Values Sheet 3 of 4...

Page 190: ...SECTION 4 BOOM PLATFORM 4 28 3121619 Figure 4 19 Boom Assembly Torque Values Sheet 4 of 4...

Page 201: ...SECTION 4 BOOM PLATFORM 3121619 4 39 Figure 4 20 Hose Adjustment...

Page 202: ...SECTION 4 BOOM PLATFORM 4 40 3121619 Figure 4 21 Section 3 Boom Cables...

Page 203: ...SECTION 4 BOOM PLATFORM 3121619 4 41 Figure 4 22 Section 4 Boom Cables...

Page 204: ...SECTION 4 BOOM PLATFORM 4 42 3121619 Figure 4 23 Section 5 Boom Cables...

Page 205: ...SECTION 4 BOOM PLATFORM 3121619 4 43 Figure 4 24 Jib Hydraulics Sheet 1 of 7...

Page 234: ...SECTION 4 BOOM PLATFORM 4 72 3121619 Figure 4 44 Powertrack Shimming Instructions...

Page 239: ...SECTION 4 BOOM PLATFORM 3121619 4 77 Figure 4 49 Powertrack Hose Installation Sheet 1 of 4...

Page 240: ...SECTION 4 BOOM PLATFORM 4 78 3121619 Figure 4 50 Powertrack Hose Installation Sheet 2 of 4...

Page 241: ...SECTION 4 BOOM PLATFORM 3121619 4 79 Figure 4 51 Powertrack Hose Installation Sheet 3 of 4...

Page 242: ...SECTION 4 BOOM PLATFORM 4 80 3121619 Figure 4 52 Powertrack Hose Installation Sheet 4 of 4...

Page 252: ...SECTION 4 BOOM PLATFORM 4 90 3121619 NOTES...

Page 432: ...SECTION 5 BASIC HYDRAULIC INFORMATION HYDRAULIC SCHEMATICS 5 180 3121619 NOTES...

Page 527: ...SECTION 6 JLG CONTROL SYSTEM 3121619 6 95 Figure 6 36 LSS Installation Sheet 1 of 4...

Page 528: ...SECTION 6 JLG CONTROL SYSTEM 6 96 3121619 Figure 6 37 LSS Installation Sheet 2 of 4...

Page 529: ...SECTION 6 JLG CONTROL SYSTEM 3121619 6 97 Figure 6 38 LSS Installation Sheet 3 of 4...

Page 530: ...SECTION 6 JLG CONTROL SYSTEM 6 98 3121619 Figure 6 39 LSS Installation Sheet 4 of 4...

Page 710: ...SECTION 7 BASIC ELECTRICAL INFORMATION ELECTRICAL SCHEMATICS 7 118 3121619 NOTES...

Page 711: ......