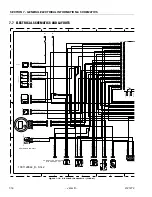

SECTION 7 - GENERAL ELECTRICAL INFORMATION & SCHEMATICS

3121273

– JLG Lift –

7-1

SECTION 7. GENERAL ELECTRICAL INFORMATION & SCHEMATICS

7.1 GENERAL

This section contains schematics to be used for locating and correcting most of the operating problems which may develop.

If a problem should develop which is not presented in this section or which is not corrected by listed corrective actions, tech-

nically qualified guidance should be obtained before proceeding with any maintenance.

IT IS A GOOD PRACTICE TO AVOID PRESSURE-WASHING ELECTRICAL/ELECTRONIC COMPONENTS. SHOULD PRESSURE-WASHING BE

UTILIZED TO WASH AREAS CONTAINING ELECTRICAL/ELECTRONIC COMPONENTS, JLG INDUSTRIES, INC. RECOMMENDS A MAXIMUM

PRESSURE OF 750 PSI (52 BAR) AT A MINIMUM DISTANCE OF 12 INCHES (30.5 CM) AWAY FROM THESE COMPONENTS. IF ELECTRICAL/

ELECTRONIC COMPONENTS ARE SPRAYED, SPRAYING MUST NOT BE DIRECT AND BE FOR BRIEF TIME PERIODS TO AVOID HEAVY

SATURATION.

7.2 MULTIMETER BASICS

A wide variety of multimeters or Volt Ohm Meters (VOM) can be used for troubleshooting your equipment. A digital meter

with reasonable accuracy (within 7%) is recommended for the measurements in these procedures. This section shows dia-

grams of a common, digital VOM configured for several different circuit measurements. Instructions for your VOM may vary.

Please consult the meter operator’s manual for more information.

Grounding

"Grounding the meter" means to take the black lead (which is connected to the COM (common) or negative port) and touch

it to a good path to the negative side of the voltage source.

Backprobing

To "backprobe" means to take the measurement by accessing a connector’s contact on the same side as the wires, the back

of the connector. Readings can be done while maintaining circuit continuity this way. If the connector is the sealed type,

great care must be taken to avoid damaging the seal around the wire. It is best to use probes or probe tips specifically

designed for this technique, especially on sealed connectors. Whenever possible insert probes into the side of the connec-

tor such that the test also checks both terminals of the connection. It is possible to inspect a connection within a closed con-

nector by backprobing both sides of a connector terminal and measuring resistance. Do this after giving each wire a gentle

pull to ensure the wires are still attached to the contact and contacts are seated in the connector.

Min/Max

Use of the "Min/Max" recording feature of some meters can help when taking measurements of intermittent conditions while

alone. For example, you can read the voltage applied to a solenoid when it is only operational while a switch, far from the

solenoid and meter, is held down.

Polarity

Finding a negative voltage or current reading when expecting a positive reading frequently means the leads are reversed.

Check what reading is expected, the location of the signal and that the leads are connected to the device under test cor-

rectly. Also check that the lead on the "COM" port goes to the ground or negative side of the signal and the lead on the other

port goes to the positive side of the signal.

Scale

M = Mega = 1,000,000 * (Displayed Number)

k = kilo = 1,000 * (Displayed Number)

m = milli = (Displayed Number) / 1,000

μ

= micro = (Displayed Number) / 1,000,000

Example: 1.2 k

Ω

= 1200

Ω

Example: 50 mA = 0.05 A