SECTION 3 - CHASSIS & SCISSOR ARMS

3-2

– JLG Lift –

3121273

3.2 BATTERY REMOVAL/MAINTENANCE

NOTICE

JLG MACHINES EQUIPPED WITH DELTA Q BATTERY CHARGERS

ARE DESIGNED FOR THE BEST PERFORMANCE WITH OEM FAC-

TORY APPROVED BATTERIES.

APPROVED JLG REPLACEMENT BATTERIES ARE AVAILABLE

THROUGH JLG'S AFTERMARKET PARTS DISTRIBUTION CEN-

TERS OR JLG'S AFTERMARKET PROGRAMS. FOR ASSISTANCE

WITH PROPER BATTERY REPLACEMENT, PLEASE CONTACT

YOUR LOCAL JLG SUPPORT OFFICE.

BATTERIES APPROVED BY JLG HAVE BEEN TESTED FOR COM-

PATIBILITY WITH THE ALGORITHM PROGRAMMING OF THE

DELTA Q BATTERY CHARGER TO OPTIMIZE BATTERY LIFE AND

MACHINE CYCLE TIMES. THE USE OF NON APPROVED BATTER-

IES IN YOUR JLG EQUIPMENT MAY RESULT IN PERFORMANCE

ISSUES OR BATTERY CHARGER FAULT CODES. JLG ASSUMES

NO RESPONSIBILITY FOR SERVICE OR PERFORMANCE ISSUES

ARISING FROM THE USE OF NON APPROVED BATTERIES.

Battery Quick-Disconnect -

(If Equipped)

Machines equipped with the battery

quick-disconnect allow all machine

power to be easily disconnected at

the batteries without removing bat-

tery cables from the battery posts. To disconnect power,

locate the RED quick-disconnect connector on top of the

batteries inside the battery compartment and pull halves

apart.

CAUTION

BEFORE BATTERY REMOVAL CAN BEGIN, ENSURE THAT THE (+)

AND (—) BATTERY CABLES HAVE BEEN PROPERLY DISCON-

NECTED.

1. The machine batteries are located inside the

machine right side cover, remove the cover.

2. Once the battery door is removed from the machine,

battery replacement/maintenance can begin.

3. To remove one or more batteries from the machine,

the battery hold down bar will need to be removed.

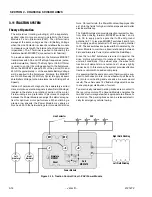

(See Figure 3-2.)

4. Remove the (2) nuts and washers from each hold-

down anchor at the ends of the hold-down bar.

Remove the bar and lay aside.

5. After battery removal and installation re-install the

battery hold down bar.

6. After any maintenance on the batteries or replace-

ment of the batteries is complete, reconnect the bat-

teries and check for proper operation.

7. Re-install the machine right side cover.

Battery Maintenance and Safety Practices

CAUTION

ENSURE THAT BATTERY ACID DOES NOT COME INTO CONTACT

WITH SKIN OR CLOTHING. WEAR PROTECTIVE CLOTHING AND

EYEWEAR WHEN WORKING WITH BATTERIES. NEUTRALIZE ANY

BATTERY ACID SPILLS WITH BAKING SODA AND WATER.

BATTERY ACID RELEASES AN EXPLOSIVE GAS WHILE CHARG-

ING, ALLOW NO OPEN FLAMES, SPARKS OR LIGHTED TOBACCO

PRODUCTS IN THE AREA WHILE CHARGING BATTERIES.

CHARGE BATTERIES ONLY IN A WELL VENTILATED AREA.

ADD ONLY DISTILLED WATER TO BATTERIES. WHEN ADDING

WATER TO THE BATTERIES, A NON-METALLIC CONTAINER AND/

OR FUNNEL MUST BE USED.

DO NOT REPLACE ITEMS CRITICAL TO STABILITY, SUCH AS

BATTERIES, WITH ITEMS OF DIFFERENT WEIGHT OR SPECIFICA-

TION. DO NOT MODIFY UNIT IN ANY WAY TO AFFECT STABILITY.

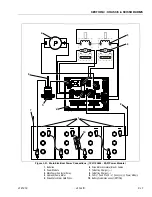

Check the electrolyte level of the batteries often, adding

only distilled water when required. When fully charged,

battery fluid level should be 1/8" below vent tubes.

(See

.

• DO NOT fill to bottom of vent tubes.

• DO NOT allow fluid level to go below the top of the

plates when charging or operating.

• Clean terminal connections if they become corroded.

1706740A

Figure 3-2. Battery Location and Hold Down Bar

(All Models)

1.

Batteries (4 - 6V)

2.

Hold-Down Bar

3.

Hold-Down Bar Fasteners

1

2

3

3