SECTION 3 - CHASSIS & SCISSOR ARMS

3121273

– JLG Lift –

3-13

Tilt Sensor Removal

1. Disconnect power at the batteries.

2. Remove the machine left side cover (ground control

station side).

3. Unplug the tilt sensor 3-wire harness connector.

4. Remove the two (2) mounting nuts, bolts and wash-

ers attaching the sensor to the base frame.

Tilt Sensor Installation

1. Before mounting the tilt sensor to the base frame,

check the mating surfaces of the sensor and the

mounting plate, be certain there is no debris or burrs

to prevent a flush mount.

2. When mounting the tilt sensor back into the base

frame, align the mounting pin on the bottom of the

sensor with the hole in the mounting plate on the

base frame

(item 2 - Figure 3-16.)

.

3. Secure to the base frame with the mounting hard-

ware.

4. Adjust per instructions following.

Tilt Sensor Switch - Adjustment Procedure

NOTICE

PERFORM TILT SWITCH LEVELING PROCEDURE A MINIMUM OF

EVERY SIX MONTHS TO ENSURE PROPER OPERATION AND

ADJUSTMENT OF SWITCH.

1. Park the machine on a smooth, firm, and level sur-

face. Be sure it is as level as possible.

NOTE:

Ensure switch mounting is level and securely

attached.

2. Tighten the three flange nuts with a socket wrench.

Each nut should be tightened approximately one-

quarter of its spring’s travel.

3. Using bubble level on top of indicator, Tighten or

loosen the three flange nuts until indicator is level.

4. Individually push down on one corner at a time.

There should be enough travel to cause the indica-

tor to trip. If the indicator does not trip in all three

tests, the flange nuts have been tightened too far.

Figure 3-17. Tilt Sensor Switch - Bubble Level

1. Level

2. Not Level

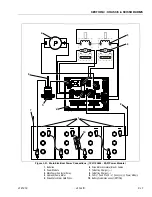

Figure 3-18. Tilt Sensor Switch - Adjustment

1. Flange Adjusting Nuts

2. Bubble Level

1

2

1

1

1

2