SECTION 1 - GENERAL SPECIFICATIONS

1-4

31215808

1.9

BATTERY MAINTENANCE

NOTE:

This information applies to wet cell batteries only. Do not

attempt to open a maintenance-free sealed battery.

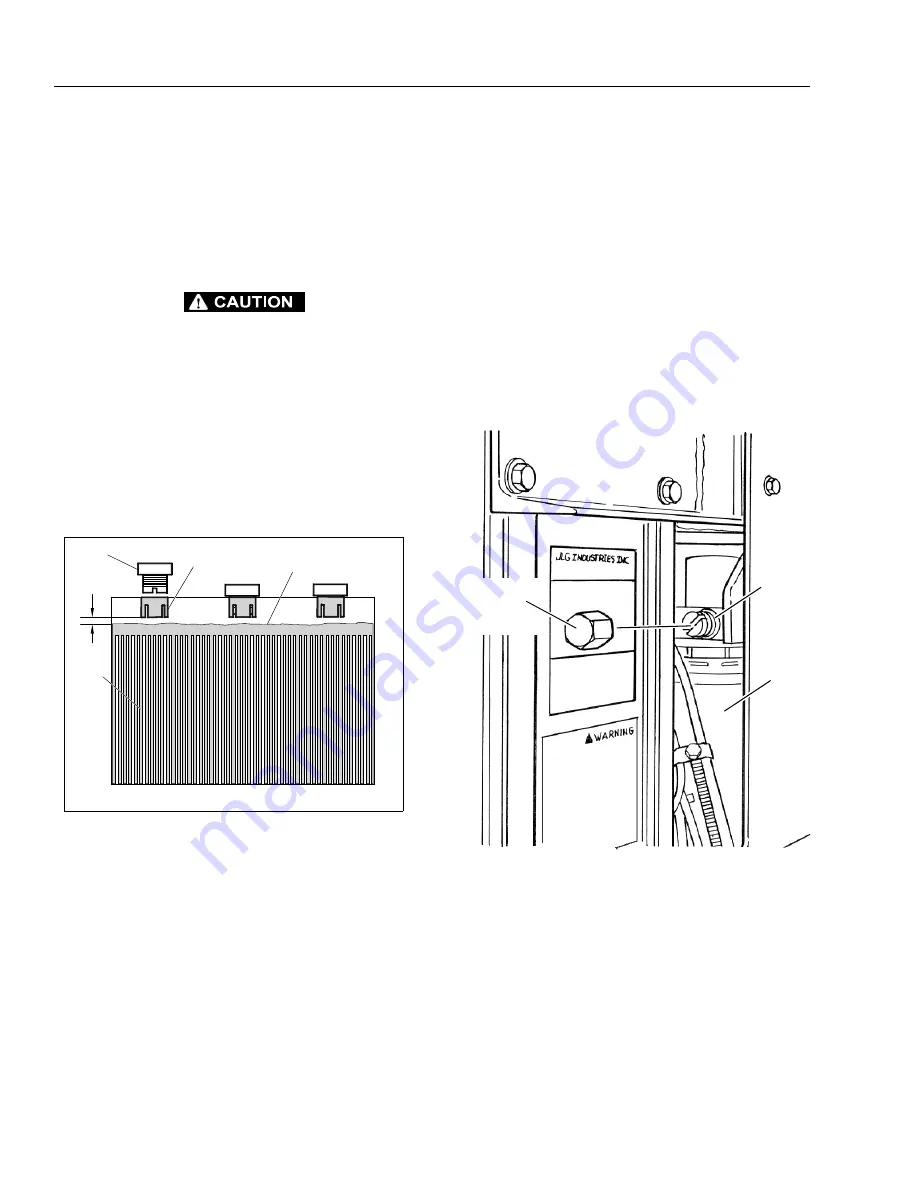

Battery fluid level should be approximately 1/8 in. (3mm)

below vent tubes. (See Illustration).

Keep cable connections clean and free of corrosion.

BATTERY ACID IS HIGHLY CORROSIVE. AVOID CONTACT WITH SKIN AND CLOTH-

ING AT ALL TIMES.

BATTERY ACID RELEASES AN EXPLOSIVE GAS WHILE CHARGING, ALLOW NO

OPEN FLAMES, SPARKS OR LIGHTED TOBACCO PRODUCTS IN THE AREA WHILE

CHARGING BATTERIES. CHARGE BATTERIES ONLY IN A WELL VENTILATED

AREA.

ADD ONLY DISTILLED WATER TO BATTERIES. WHEN ADDING DISTILLED WATER

TO THE BATTERIES, A NON-METALLIC CONTAINER AND/OR FUNNEL MUST BE

USED.

1.10 HYDRAULIC PRESSURE ADJUSTMENT

Adjust system pressure so that platform will raise with rated

capacity in platform.

Turning adjustment screw clockwise, increases system pres-

sure, turning screw counterclockwise, decreases system pres-

sure.

Do not adjust system pressure higher than required to raise

the load. Make pressure adjustment with oil at normal operat-

ing temperature. If pressure is set when oil is cold, platform

may not raise rated load after oil has warmed.

MAF30650

4

1/8 in.

(3mm)

2

1

3

1.

Battery Filler Cap

2.

Vent Tube

3.

Fluid Level

4.

Cell Plates

Figure 1-1. Battery Fluid Level

Figure 1-2. Hydraulic Pressure Setting - Adjust-

ment Screw Located at Base of Pump Motor

(Remove Hex Head Cap as Shown)

PRESSURE

ADJUSTMENT

SCREW

HYDRAULIC

OIL

TANK

GROUND

CONTROL

STATION

COVER

ADJUSTMENT

SCREWCAP

(SHOWNREMOVED)

Go

to

Discount-Equipment.com

to

order

your

parts