SECTION 1 - GENERAL SPECIFICATIONS

31215808

1-7

1.13

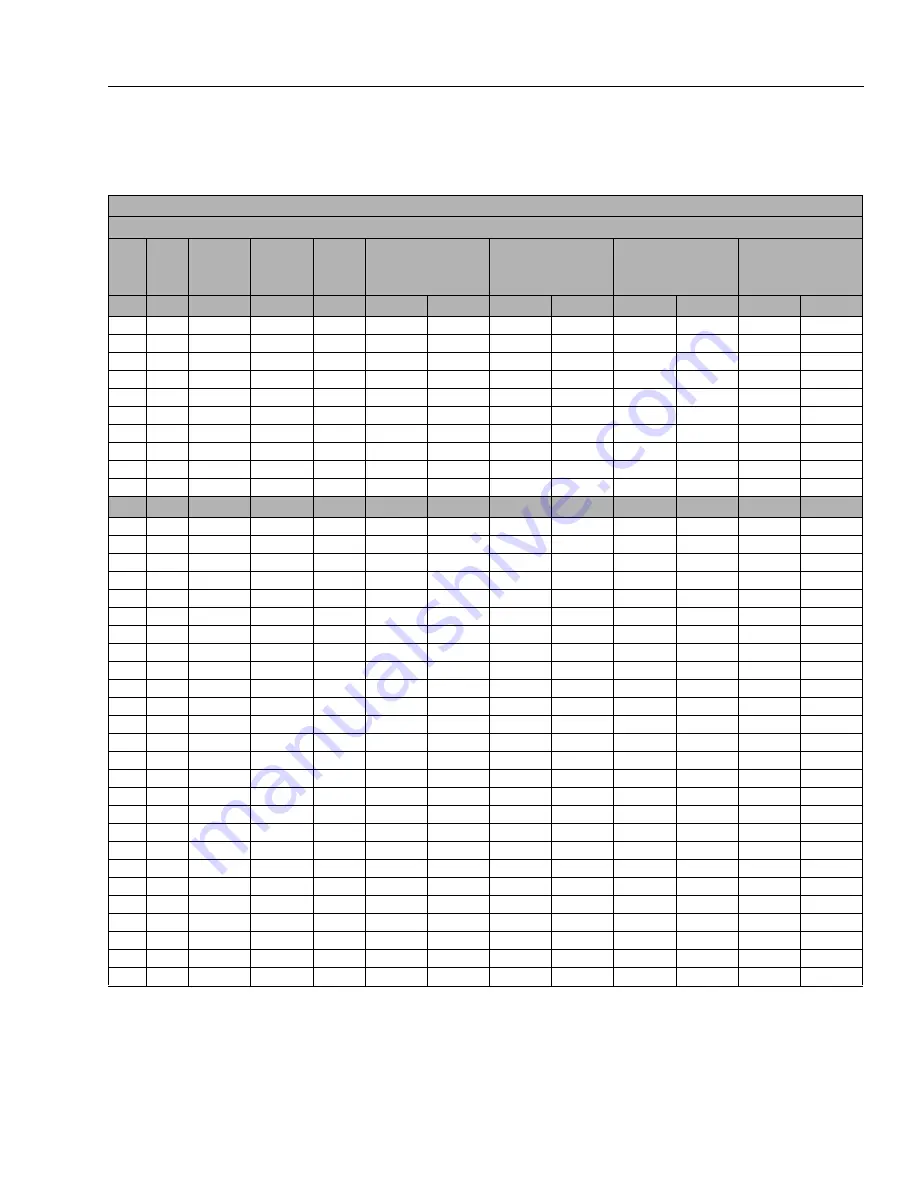

TORQUE CHARTS

SAE Fastener Torque Chart

Values for Zinc Yellow Chromate Fasteners (Ref 4150707)

SAE GRADE 5 BOLTS & GRADE 2 NUTS

Size

TPI

Bolt Dia

Tensile

Stress Area

Clamp

Load

Torque

(Dry)

Torque

Lubricated

Torque

(Loctite® 242™ or 271™ or

Vibra-TITE™ 111 or 140)

Torque

(Loctite® 262™

or

Vibra-TITE™ 111)

In

Sq In

LB

IN-LB

[N.m]

IN-LB

[N.m]

IN-LB

[N.m]

IN-LB

[N.m]

4

40

0.1120

0.00604

380

8

0.9

6

0.7

48

0.1120

0.00661

420

9

1.0

7

0.8

6

32

0.1380

0.00909

580

16

1.8

12

1.4

40

0.1380

0.01015

610

18

2.0

13

1.5

8

32

0.1640

0.01400

900

30

3.4

22

2.5

36

0.1640

0.01474

940

31

3.5

23

2.6

10

24

0.1900

0.01750

1120

43

4.8

32

3.5

32

0.1900

0.02000

1285

49

5.5

36

4

1/4

20

0.2500

0.0318

2020

96

10.8

75

9

105

12

28

0.2500

0.0364

2320

120

13.5

86

10

135

15

In

Sq In

LB

FT-LB

[N.m]

FT-LB

[N.m]

FT-LB

[N.m]

FT-LB

[N.m]

5/16

18

0.3125

0.0524

3340

17

23

13

18

19

26

16

22

24

0.3125

0.0580

3700

19

26

14

19

21

29

17

23

3/8

16

0.3750

0.0775

4940

30

41

23

31

35

48

28

38

24

0.3750

0.0878

5600

35

47

25

34

40

54

32

43

7/16

14

0.4375

0.1063

6800

50

68

35

47

55

75

45

61

20

0.4375

0.1187

7550

55

75

40

54

60

82

50

68

1/2

13

0.5000

0.1419

9050

75

102

55

75

85

116

68

92

20

0.5000

0.1599

10700

90

122

65

88

100

136

80

108

9/16

12

0.5625

0.1820

11600

110

149

80

108

120

163

98

133

18

0.5625

0.2030

12950

120

163

90

122

135

184

109

148

5/8

11

0.6250

0.2260

14400

150

203

110

149

165

224

135

183

18

0.6250

0.2560

16300

170

230

130

176

190

258

153

207

3/4

10

0.7500

0.3340

21300

260

353

200

271

285

388

240

325

16

0.7500

0.3730

23800

300

407

220

298

330

449

268

363

7/8

9

0.8750

0.4620

29400

430

583

320

434

475

646

386

523

14

0.8750

0.5090

32400

470

637

350

475

520

707

425

576

1

8

1.0000

0.6060

38600

640

868

480

651

675

918

579

785

12

1.0000

0.6630

42200

700

949

530

719

735

1000

633

858

1 1/8

7

1.1250

0.7630

42300

800

1085

600

813

840

1142

714

968

12

1.1250

0.8560

47500

880

1193

660

895

925

1258

802

1087

1 1/4

7

1.2500

0.9690

53800

1120

1518

840

1139

1175

1598

1009

1368

12

1.2500

1.0730

59600

1240

1681

920

1247

1300

1768

1118

1516

1 3/8

6

1.3750

1.1550

64100

1460

1979

1100

1491

1525

2074

1322

1792

12

1.3750

1.3150

73000

1680

2278

1260

1708

1750

2380

1506

2042

1 1/2

6

1.5000

1.4050

78000

1940

2630

1460

1979

2025

2754

1755

2379

12

1.5000

1.5800

87700

2200

2983

1640

2224

2300

3128

1974

2676

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

5000059K

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

3. * ASSEMBLY USES HARDENED WASHER

Go

to

Discount-Equipment.com

to

order

your

parts