SECTION 4 - BASIC HYDRAULIC INFORMATION & SCHEMATICS

4-12

3121788

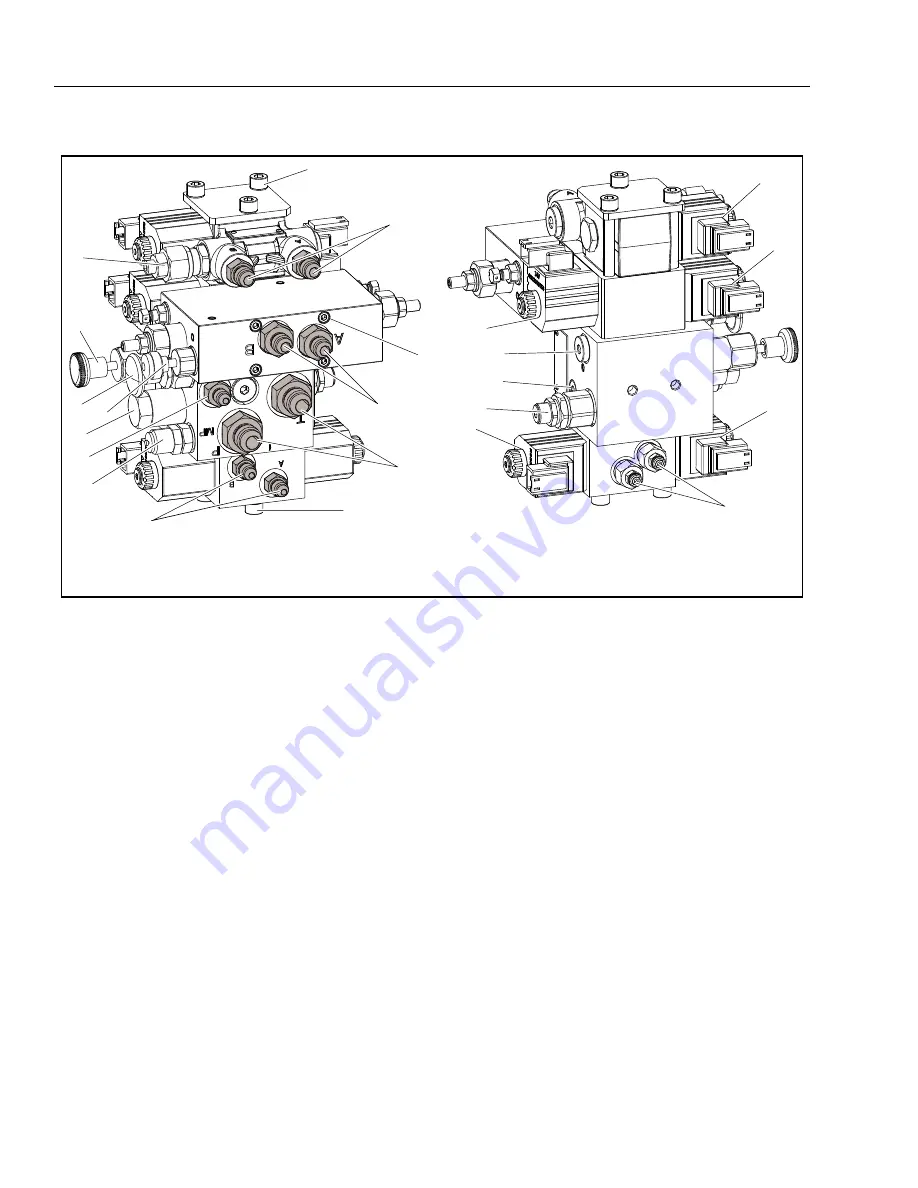

Figure 4-9. Hydraulic Manifold Assembly - Component Torque

1.

Socket Head Screws - 16 ft. lb. (21 Nm)

2.

Screw - 4 ft. lb. (5.5 Nm)

3.

Pressure/Tank Port Fittings - 59 ft. lb. (79 Nm)

4.

Port A/B Fittings - Drive - 36 ft. lb. (49 Nm)

5.

Brake Port Fittings - 20 ft. lb. (27 Nm)

6.

Port A/B Fitting - Lift - 31 ft. lb. (42 Nm)

7.

Port B Fitting - Steer - 23 ft. lb. (31 Nm)

8.

MP Port Fitting - 50 ft. lb. (20 Nm)

9.

Needle Valve - 26 ft. lb. (35 Nm)

10.

Relief Valve - Lift - 31 ft. lb. (43 Nm)

11.

Hand Pump - 28 ft. lb. (38 Nm)

12.

Brake Release Valve - 33 ft. lb. (45 Nm)

13.

Bypass Valve - 33 ft. lb. (45 Nm)

14.

Main Relief Valve - 31 ft. lb. (43 Nm)

15.

Steer Relief Valves - 7 ft. lb. (9.5 Nm)

16.

Solenoid Valves - 4 ft. lb. (5.5 Nm)

(Coil Resistance 22 Ohms)

17.

Plug - 9 ft. lb. (12.5 Nm)

18.

Plug - 23 ft. lb. (32 Nm)

MAF10640

1

7

1

10

6

11

12

9

2

4

3

8

5

13

16

17

18

14

16

15

16

16

16

RIGHT FRONT VIEW

LEFT REAR VIEW

Go to

Discount-Equipment.com

to

order your

parts