SECTION 4 - BASIC HYDRAULIC INFORMATION & SCHEMATICS

3121788

4-23

4.14 CYLINDER REPAIR

NOTE:

The following are general procedures that apply to

the cylinders on this machine. Procedures that apply

to a specific cylinder will be so noted.

Disassembly

NOTICE

DISASSEMBLY OF THE CYLINDER SHOULD BE PERFORMED ON A CLEAN

WORK SURFACE IN A DIRT FREE WORK AREA.

1.

Connect a suitable auxiliary hydraulic power

source to the port block fitting in the manifold

located on the cylinder.

DO NOT FULLY EXTEND CYLINDER TO THE END OF STROKE. RETRACT

CYLINDER SLIGHTLY TO AVOID TRAPPING PRESSURE.

2.

Operate the hydraulic power source and extend

the cylinder. Shut down and disconnect the

power source. Adequately support the cylinder

rod, if applicable.

3.

If applicable, remove the cartridge-type holding

valve and fittings from the cylinder port block.

Discard o-rings.

4.

Place the cylinder barrel into a suitable holding

fixture.

5.

Mark cylinder head and barrel with a center

punch for easy realignment. Loosen the cylinder

head setscrew.

6.

Using the proper wrench, loosen the cylinder

head and remove head from cylinder barrel.

When removing cylinder head do not force if

binding occurs. Reverse rotation a couple times

and try removing again. If still no release, tap

barrel with hammer in threaded area, and try

again. Repeat if necessary, until head is com-

pletely removed.

7.

Attach a suitable pulling device to the cylinder

rod port block end or cylinder rod end, as appli-

cable.

NOTICE

EXTREME CARE SHOULD BE TAKEN WHEN REMOVING THE CYLINDER

ROD, HEAD, AND PISTON. AVOID PULLING THE ROD OFF-CENTER,

WHICH COULD CAUSE DAMAGE TO THE PISTON AND CYLINDER BAR-

REL SURFACES.

8.

With the barrel clamped securely, apply pressure

to the rod pulling device and carefully withdraw

the complete rod assembly from the cylinder

barrel.

9.

Using suitable protection, clamp the cylinder rod

in a vise or similar holding fixture as close to the

piston as possible.

10.

Loosen and remove the capscrew(s), if applica-

ble, which attach the tapered bushing to the pis-

ton.

11.

Insert the capscrew(s) in the threaded holes in

the outer piece of the tapered bushing. Progres-

sively tighten the cap screw(s) until the bushing

is loose on the piston.

12.

Remove the bushing from the piston.

13.

Screw the piston CCW, by hand, and remove the

piston from cylinder rod.

14.

Remove and discard the piston o-rings, seal

rings, and backup rings.

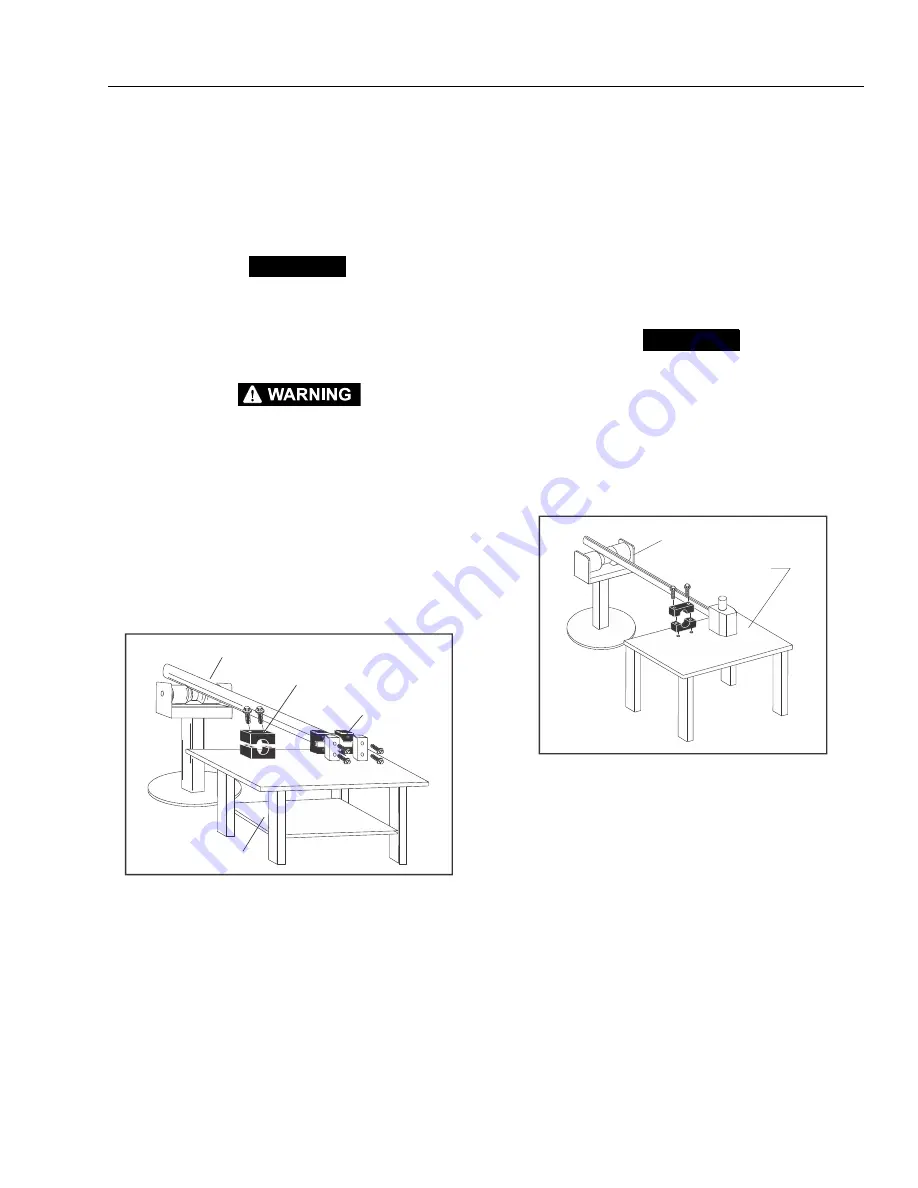

ROD SUPPORT

PROTECTED ROD CLAMP

BARREL CLAMP

SUPPORT TABLE

Figure 4-19. Cylinder Barrel Support

SUPPORT TABLE

ROD SUPPORT

Figure 4-20. Cylinder Rod Support

Go to

Discount-Equipment.com

to

order your

parts