SECTION 3 - CHASSIS & SCISSOR ARMS

3121133

– JLG Sizzor –

3-15

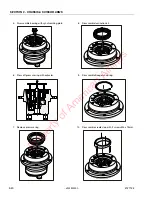

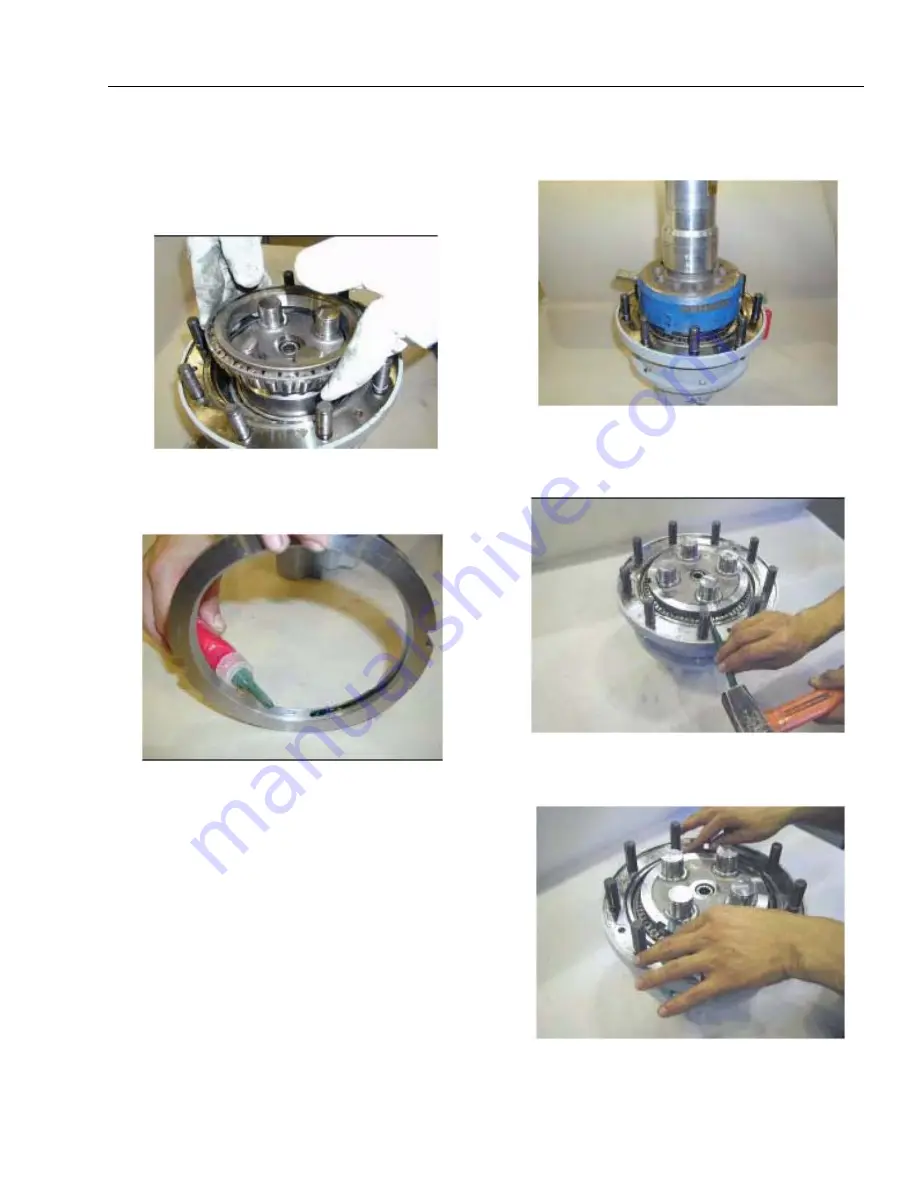

8.

Heat upper ring with roller cage of double Tapered

Roller Bearing (11) to approximately 189.5°F/70°C

and mount onto Spindle (34). Allow cooling time of

approximately 15 minutes before continuing assem-

bly.

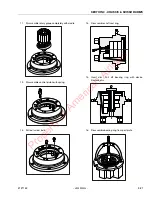

9.

De-grease threads of Spindle (34) and Shaft Nut (4).

Then evenly apply coat of Loctite 270 to Shaft Nut

(4) threads.

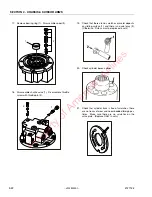

10.

Rotate the supporitng ring repeatedly in one direc-

tion only when setting the tapered roller bearing.

a. Tighten Shaft Nut (4) by using an adequate

device with a tightening torque of 627 lb-ft (850

Nm).

b. The Loctite setting time equals 24 hours at ambi-

ent temperature of 68°F/20°C.

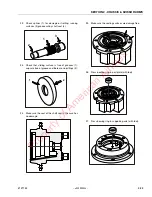

11.

After proper bearing setting is completed, hammer

ball with suitable punch, 1.1 - 1.3mm into the spindle

thread. Retain ball in position with expanding plug.

12.

Insert a new greased O-Ring (16) into the o-ring

groove of the Supporting Ring (6).

Property of American Airlines