SECTION 4 - HYDRAULICS

3121133

– JLG Lift –

4-3

8.

Place the 6 inch (15.2 cm) high block with ascension

ramp in front of right front wheel.

9.

From platform control station, select LOW drive

speed.

10.

Place DRIVE control switch to FORWARD position

and carefully drive the machine up ascension ramp

until right front wheel is on top of block.

11.

Raise machine platform approximately 9 ft (2.7 m)

on the 3394RT or 10 ft (3.1 m) on the 4394RT.

12.

Place DRIVE control switch to REVERSE position

and carefully drive the machine off the block and

ramp.

13.

Have an assistant check to see that the right front

wheel remains locked in position off the ground.

14.

Lower the machine platform; the lockout cylinder

should then release and allow wheel to rest on the

ground. It may be necessary to activate DRIVE to

release cylinders.

15.

If the lockout cylinders do not function properly,

have qualified personnel correct the malfunction

prior to any further operation.

4.5

CYLINDER REPAIR

NOTE:

The following are general procedures that apply to

all of the cylinders on this machine. Procedures that

apply to a specific cylinder will be so noted.

Disassembly

NOTICE

DISASSEMBLY OF THE CYLINDER SHOULD BE PERFORMED ON

A CLEAN WORK SURFACE IN A DIRT FREE WORK AREA.

1.

Connect a suitable auxiliary hydraulic power source

to the cylinder port block fitting.

DO NOT FULLY EXTEND CYLINDER TO THE END OF STROKE.

RETRACT CYLINDER SLIGHTLY TO AVOID TRAPPING PRES-

SURE.

2.

Operate the hydraulic power source and extend the

cylinder. Shut down and disconnect the power

source. Adequately support the cylinder rod, if appli-

cable.

3.

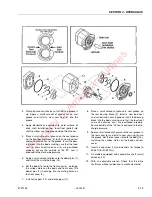

If applicable, remove the cartridge-type holding

valve and fittings from the cylinder port block. Dis-

card o-rings.

4.

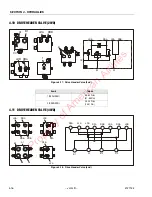

Place the cylinder barrel into a suitable holding fix-

ture.

Figure 4-1. Lift Cylinder Holding Valve and Fitting

Removal

Figure 4-2. Cylinder Barrel Support

Property of American Airlines