SECTION 4 - BOOM & PLATFORM

31215031

4-23

3.

Remove mounting hardware from lift cylinder pin #7.

Using a suitable brass drift and hammer, remove the cyl-

inder pin from articulating jib boom.

Inspection

NOTE:

When inspecting pins and bearings Refer to Section 2.5 -

Pins and Composite Bearing Repair Guidelines.

1.

Inspect fly boom pivot pin for wear, scoring, tapering

and ovality, or other damage. Replace pins as necessary.

2.

Inspect fly boom pivot attach points for scoring, taper-

ing and ovality, or other damage. Replace pins as neces-

sary.

3.

Inspect inner diameter of fly boom pivot bearings for

scoring, distortion, wear, or other damage. Replace bear-

ings as necessary.

4.

Inspect lift cylinder attach pin for wear, scoring, tapering

and ovality, or other damage. Ensure pin surfaces are

protected prior to installation. Replace pins as neces-

sary.

5.

Inspect inner diameter of rotator attach point bearings

for scoring, distortion, wear, or other damage.

6.

Inspect all threaded components for damage such as

stretching, thread deformation, or twisting. Replace as

necessary.

7.

Inspect structural units of jib boom assembly for bend-

ing, cracking, separation of welds, or other damage.

Replace boom sections as necessary.

Assembly

1.

Align lift cylinder with attach holes in jib assembly.

Using a soft head mallet, install cylinder pin #7 into jib

and secure with mounting hardware.

2.

Align rotator support with attach hole in jib assembly.

Using a soft head mallet, install rotator support pin #6

into jib and secure with mounting hardware.

3.

Align bottom tubes with attach holes in rotator support.

Using a soft head mallet, install rotator support pin #5

into jib assembly and secure with mounting hardware.

4.

Align jib assembly with attach hole in jib boom pivot

weldment. Using a soft head mallet, install rotator sup-

port pin #4 into jib assembly and secure with mounting

hardware.

5.

Align bottom tubes with attach holes in jib boom pivot

weldment. Using a soft head mallet, install rotator sup-

port pin #3 into jib boom pivot weldment and secure

with mounting hardware.

Installation

1.

Align jib boom pivot weldment with attach holes in fly

boom assembly. Using a soft head mallet, install pivot

pin #2 into fly boom assembly and secure with mount-

ing hardware.

2.

Align the slave leveling cylinder with attach holes in jib

boom pivot weldment. Using a soft head mallet, install

slave leveling cylinder pin #1 into articulating jib boom

pivot weldment and secure with mounting hardware.

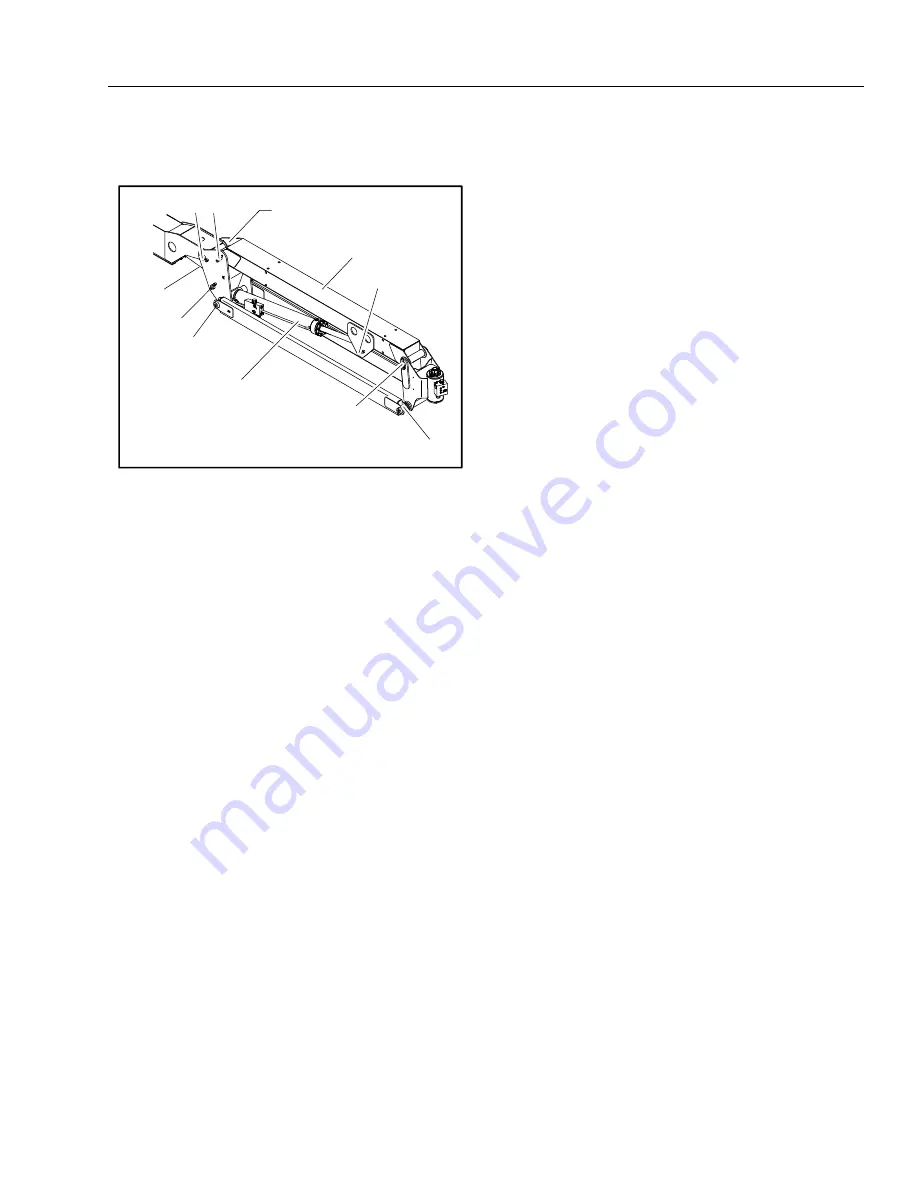

6

5

SLAVE

CYLINDER

7

JIB LIFT

CYLINDER

JIB PIVOT

1

2 4

JIB

3

Figure 4-11. Jib Assembly

Go

to

Discount-Equipment.com

to

order

your

parts