SECTION 3 - CHASSIS & TURNTABLE

3-18

31215031

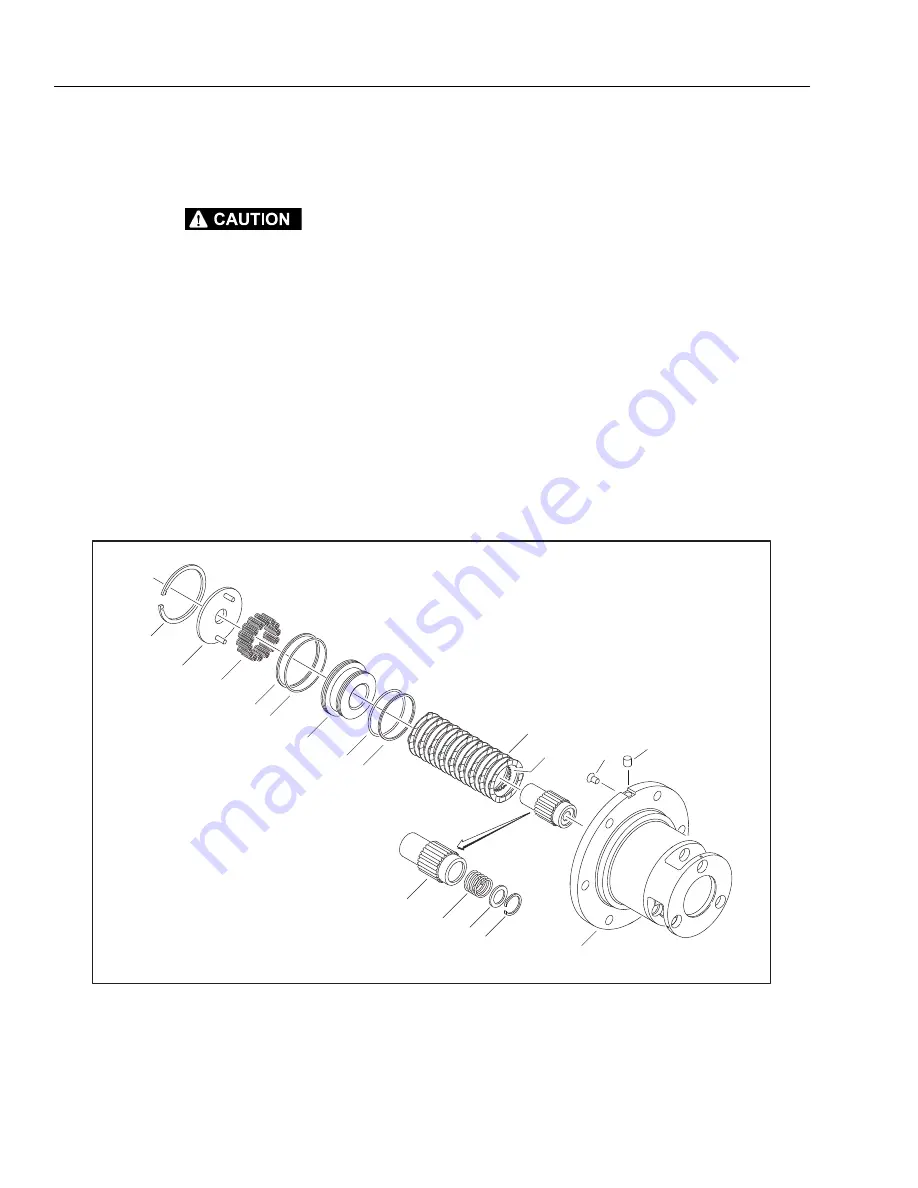

Spindle-Brake Disassembly

NOTE:

Units with integral Input Brake (8) only.

COMPRESSED SPRINGS CAN FLY OUT AND CAUSE SEVERE EYE DAMAGE OR

OTHER INJURIES. WEAR EYE PROTECTION WHEN PERFORMING THESE PROCE-

DURES.

1.

Install two 1/4"-20 x 5/8" Flat Head Capscrews (22)

through Pressure Plate (8B) into Piston (8A). Tighten

incrementally until spring force is taken off Retaining

Ring (8C).

NOTE:

Flat Head Capscrews (22) are for transit and service only

and are removed before shipping new units. They are

included in most brake repair kits.

2.

Using retaining ring pliers, remove Retaining Ring (8C)

from groove in Spindle (1A).

3.

Back Flat Head Capscrews (22) incrementally out of Piston

(8A) until spring force is relieved from Pressure Plate (8B).

Remove Flat Head Capscrews (22) and Pressure Plate (8B)

from brake cavity in Spindle (1A).

4.

Remove Compression Springs (8L) from Piston (8A).

5.

Using an air hose, slowly and carefully pressurize brake

port in Spindle (1A) until Piston (8A) comes out of piston

bore of Spindle (1A). Pull Piston (8A) out of Spindle (1A)

by hand.

6.

Remove Backup Rings (8E and 8H) and O-rings (8D and

8F) from grooves in Piston (8A).

7.

Remove Rotors (8J) and Stators (8K) from brake cavity in

Spindle (1A).

8.

Remove Coupling Subassembly (7) from brake cavity in

Spindle (1A).

9.

Remove Retaining Ring (1K) from internal groove using

appropriate tool.

10.

Remove Spacer (1M) and Spring (1L) from bore of Cou-

pling (7).

11.

Remove Plastic Plug (12) and Pipe Plug (21) from Spindle

(1A) if applicable.

Figure 3-17. Spindle Brake Disassembly

Go

to

Discount-Equipment.com

to

order

your

parts