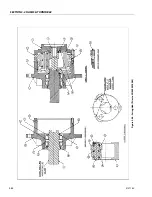

SECTION 3 - CHASSIS & TURNTABLE

3121160

3-65

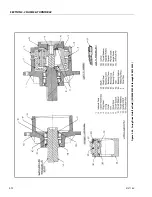

3.14 SWING HUB (SN 0300074383 THROUGH

0300134352)

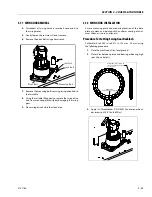

Disassembly

1.

Loosen all 12 cover bolts (12)&(13) and drain the oil from

the unit.

2.

Remove the 12 cover bolts (12)& (13) and lift off the

cover (6). Remove and discard the O-ring (5) from the

counterbore of the cover (6).

3.

Remove the input gear (8) and thrust washer (10).

4.

Lift out the carrier assembly (3) and top thrust washer

(11). The thrust washer (11) may stick to the inside of the

carrier (3).

5.

Remove the input thrust spacer (9).

6.

Lift out the internal gear (2) and thrust washer (11). The

thrust washer (11) may stick to the under side of the car-

rier (3).

7.

Remove the retaining ring (1I) from the output shaft (1A)

and discard.

EYE PROTECTION SHOULD BE WORN DURING RETAINING RING (1I) REMOVAL.

8.

Remove bearing shim (1H) from the output shaft (1A).

9.

The output shaft (1A) may now be pressed out of the

hub (1G).

10.

THe bearing cups (1C)&(1E) will remain in hub (1G) as

will bearing cone (1F). Bearing cone (1D) will remain on

the same output shaft (1A). The seal (1B) will be auto-

matically removed during this procedure.

NOTE:

If bearing replacement is necessary, the bearing cups can

be removed with a slide hammer puller driven out with a

punch.

11.

To remove the cluster gears (3F) from the carrier (3A),

drive the anti-roll pin (3G) into the planet shaft (3E) may

now be tapped out of the carrier. After planet shaft (3E)

has been removed the roll pin (3G) can be driven out.

12.

The cluster gear (3F) can now be removed from the car-

rier (3A). THe thrust washers (3B) will be removed with

the cluster gear (3F).

13.

The needle rollers (3C) and spacer (3D) are now removed

from the cluster gear (3F).

WHEN REBUILDING OR REPAIRING THE UNIT, THE RETAINING RING (1I), O-

RINGS (5) AND SEAL (1B) SHOULD ALWAYS BE REPLACED.

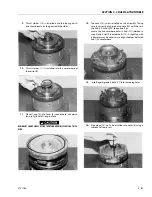

Main Assembly Procedure

1.

With the hub shaft sub-assembly resting on the shaft

(1A) install internal gear (2). The spline of the internal

gear (2) bore will mesh the spline of the output shaft

(1A).

2.

Thrust washer (11) is installed on the face of the output

shaft (1A). Sufficient grease or petroleum jelly should be

used to hold thrust washer in place.

3.

Place O-ring (5) into hub counterbore. Use petroleum

jelly to hold O-ring in place. Also at this time locate and

mark the 4 counter beamed holes in the face of the hub

(1G). This is for identification later in the assembly.

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

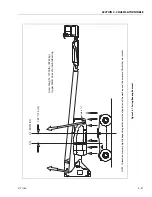

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......