SECTION 3 - CHASSIS & TURNTABLE

3121160

3-145

211

IAT High Voltage

This fault will set if the signal voltage is more than 4.95 volts anytime the engine is running. The EPM

will use the default value for the IAT sensor in the event of this fault.

212

IAT Low Voltage

This fault will set if the signal voltage is less than 0.05 volts anytime the engine is cranking or running.

The EPM will use a default value for the IAT sensor in the event

213

IAT Higher Than Expected 1

This fault will set if the Intake Air Temperature is greater than 200 °F and engine RPM is greater than

1000 and Power Derate 1 will be enforced. During this fault, maximum throttle position is 50% and the

MIL light will flash twice per second.

214

IAT Higher Than Expected 2

This fault will set if the Intake Air Temperature is greater than 210 °F and engine RPM is greater than

1000. The MIL light will be on during this active fault and the engine will shut down.

215

Oil Pressure Low

This fault can be configured two different ways. It may use a normally closed switch or a normally open

switch. If the switch is normally open, the fault will set if the circuit becomes grounded. If the switch is

normally closed, the fault will set if the circuit becomes open. Go to the Fault page on Diagnostic Tool to

determine how the input is configured. (“Open is OK” is normally open and “Ground is OK” is normally

closed). The engine will shut down in the event of this fault to help prevent possible damage.

221

ECT High Voltage

This fault will set if the signal voltage is greater than 4.95 volts anytime the engine is running. The EPM

will use a default value for the ECT sensor in the event of this fault.

222

ECT Low Voltage

This fault will set if the signal voltage is less than 0.05 volts anytime the engine is running. The EPM will

use a default value for the ECT sensor in the event of this fault.

231

MAP High Pressure

This fault will set when the MAP reading is higher than it should be for the given TPS, and RPM. When

the fault is set, the Adaptive Learn will be disabled for the remainder of the key on cycle and the MIL

will be on. The engine will operate on a default MAP during this active fault.

232

MAP Low Voltage

This fault will set when the MAP reading is lower than the sensor should normally produce. When this

fault is set the Adaptive learn will be disabled for the remainder of the key on cycle and the MIL will be

on.

234

BP High Pressure

This fault sets in the event the BP value is out of the normal range.

235

BP Low Pressure

This fault sets in the event the BP value is out of the normal range.

242

Crank Sync Noise

The EPM must see a valid Crankshaft position signal while running. If no signal is present for 800 ms or

longer, this fault will set.

243

Never Crank Synced At Start

The EPM must see a valid Crankshaft Position signal while cranking before it starts. If no signal is pres-

ent within 4 cranking revs, this fault will set.

244

Camshaft Sensor Loss

The Camshaft Position Sensor is used to determine which cylinder to fire. This fault will set if the EPM

does not detect a cam pulse when the RPM is greater than 1000. Normally the engine will run with this

fault present. In some instances this fault may cause rough engine operation.

245

Camshaft Sensor Noise

This fault will set if the EPM detects erroneous pulses from the camshaft position sensor causing

invalid cam re-sync.

253

Knock Sensor Open

This fault will set if the Knock Sensor input to the EPM is less than 0.2 volt while engine rpm is greater

than 1500 and MAP is greater than 8 psia.

254

Excessive Knock Signal

This fault will set if the Knock Sensor input to the EPM is greater than 4.5 volts while MAP is less than 8

psia and knock spark retard is at maximum.

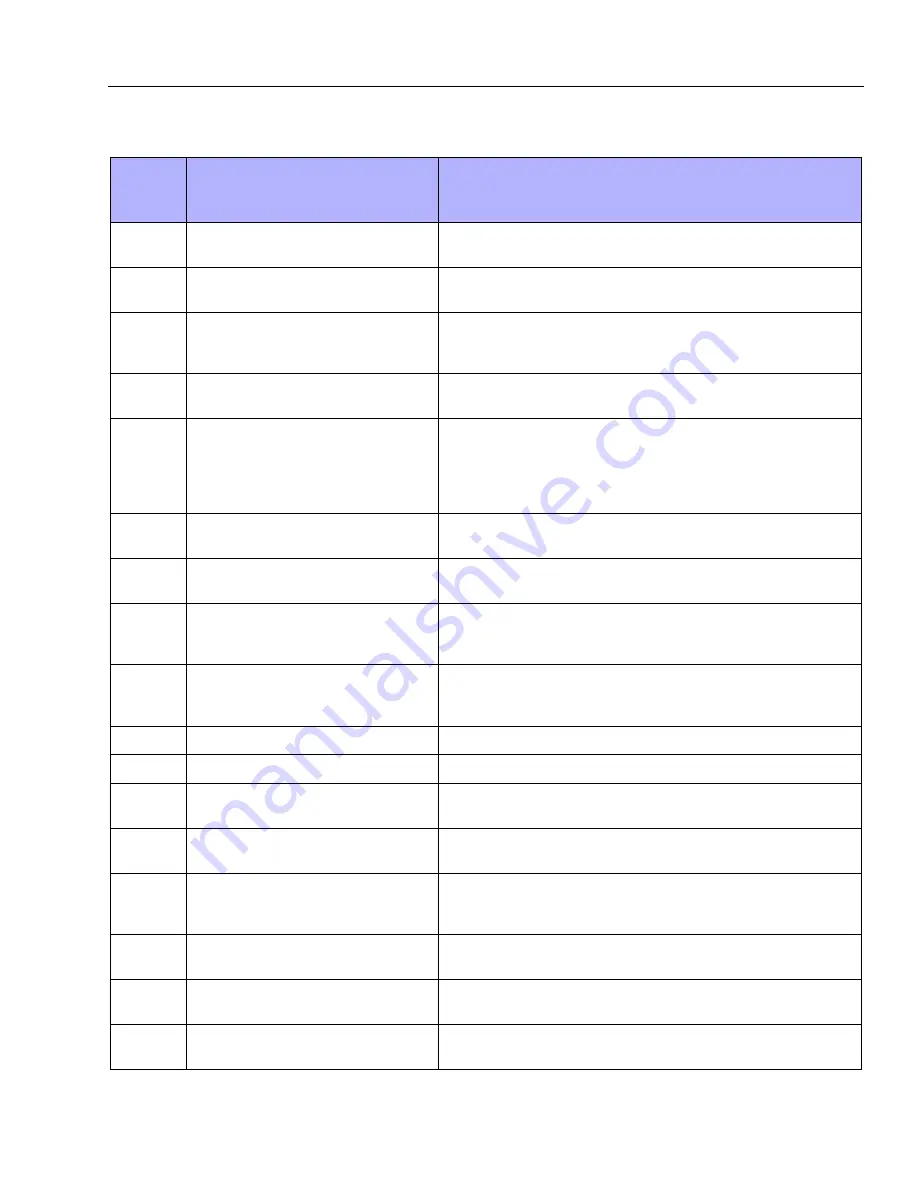

Table 3-13. EPM Diagnostic Trouble Codes

Diagnostic

Trouble

Code

Description

Cause for Setting DTC

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......