SECTION 3 - CHASSIS & TURNTABLE

3-152

3121160

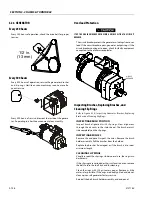

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The manifold absolute pressure (MAP) sensor responds to

changes in intake manifold pressure (vacuum). The MAP sen-

sor signal voltage to the Engine Module varies from below 2

volts at idle (high vacuum) to above 4 volts with the ignition

ON, engine not running or at wide-open throttle (low vac-

uum).

The MAP sensor is used to determine the following:

• Engine vacuum level for engine control purposes.

• Barometric pressure (BARO)

If the Engine Module detects a voltage that is significantly

lower than the estimated MAP value for 2 or more consecutive

seconds, DTC 14 will be set. A signal voltage significantly

higher than the estimated MAP value for 2 or more consecu-

tive seconds will set DTC 24.

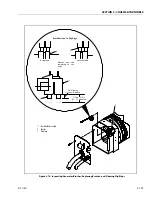

ENGINE CONTROL MODULE (ECM)/ENGINE

PERFORMANCE MODULE (EPM)

The engine will be controlled by one of two different Engine

Modules. The Ford EFI engine was originally equipped with an

ECM. The EPM was developed to replace the ECM and provide

enhanced performance and durability. To see the physical dif-

ference between the ECM and EPM, refer to Figure 3-78., ECM/

EPM Identification.

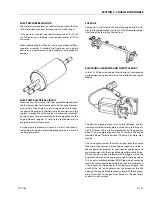

The Engine Module controls the following:

• Fuel metering system

• Ignition timing

• On-board diagnostics for engine functions

The Engine Module constantly observes the information from

various sensors. The Engine Module controls the systems that

affect engine performance. The Engine Module performs the

diagnostic function of the system. It can recognize operational

problems, alert the operator through the Malfunction Indica-

tor Lamp (MIL), and store diagnostic trouble codes (DTCs).

DTCs identify the problem areas to aid the technician in mak-

ing repairs.

The Engine Module supplies either 5 or 12 volts to power vari-

ous sensors or switches. The power is supplied through resis-

tances in the Engine Module which are so low in value that a

test light will not light when connected to the circuit. In some

cases, even an ordinary shop voltmeter will not give an accu-

rate reading because its resistance is too low. Therefore, a digi-

tal voltmeter with at least 10 meg ohms input impedance is

required to ensure accurate voltage readings. The Engine

Module controls output circuits such as the fuel injectors, elec-

tronic governor, etc., by control ling the ground or the power

feed circuit through transistors or other solid state devices.

The Engine Module is designed to maintain exhaust emission

levels to government mandated standards while providing

excellent operation and fuel efficiency. The Engine Module

monitors numerous engine functions via electronic sensors

such as the throttle position (TP) sensor and the heated oxy-

gen sensor (HO2S).

ENGINE MODULE INPUTS/OUTPUTS

Inputs - Operating Conditions

• Engine Coolant Temperature

• Crankshaft Position

• Exhaust Oxygen Content

• Manifold Absolute Pressure

• Battery Voltage

• Throttle Position

• Fuel Pump Voltage

• Intake Air Temperature

• Camshaft Position

Outputs - System Controlled

• Fuel Control

• Idle Air Control

• Electric Fuel Pump

• Diagnostics:

- Malfunction Indicator Lamp

- Data Link Connector (DLC)

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

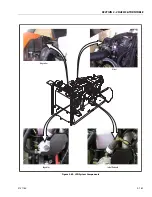

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......