SECTION

4

- BOO

M

& PLATFOR

M

3121160

4-13

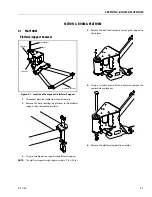

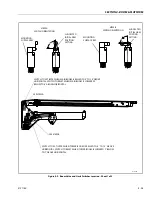

2.

To install a new bracket, slide the bracket over the links

and reinstall the pins, washers, and new snap rings. After

installing the new bracket make sure that it rotates cor-

rectly.

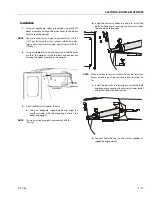

4.5

BOOM CLEANLINESS GUIDELINES

The following are guidelines for internal boom cleanliness for

machines that are used in excessively dirty environments.

1.

JLG recommends the use of the JLG Hostile Environment

Package if available to keep the internal portions of a

boom cleaner and to help prevent dirt and debris from

entering the boom. This package reduces the amount of

contamination which can enter the boom but does not

eliminate the need for more frequent inspections and

maintenance when used in these types of environ-

ments.

2.

JLG recommends that you follow all guidelines for ser-

vicing your equipment in accordance with the instruc-

tions outlined in the JLG Service & Maintenance Manual

for your machine. Periodic maintenance and inspection

is vital to the proper operation of the machine. The fre-

quency of service and maintenance must be increased

as environment, severity and frequency of usage

requires.

3.

Debris and foreign matter inside of the boom can cause

premature failure of components and should be

removed. Methods to remove debris should always be

done using all applicable safety precautions outlined in

the JLG Service & Maintenance Manuals.

4.

The first attempt to remove debris from inside the boom

must be to utilize pressurized air to blow the debris

toward the nearest exiting point from the boom. Make

sure that all debris is removed before operating the

machine.

5.

If pressurized air cannot dislodge the debris, then water

with mild solvents applied via a pressure washer can be

used. Again the method is to wash the debris toward the

nearest exiting point from the boom. Make sure that all

debris is removed, that no “puddling” of water has

occurred, and that the boom internal components are

dry prior to operating the machine. Make sure you com-

ply with all federal and local laws for disposing of the

wash water and debris.

6.

If neither pressurized air nor washing of the boom dis-

lodges and removes the debris, then disassemble the

boom in accordance to the instructions outlined in the

JLG Service & Maintenance Manual to remove the

debris.

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......