SECTION 5 - BASIC HYDRAULIC INFOR

M

ATION AND SCHE

M

ATICS

3121160

5-103

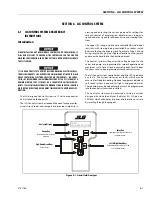

Start-up Procedure

When initially starting a new or a rebuilt transmission system.

it is extremely important that the start-up procedure be fol-

lowed. It prevents the chance of damaging the unit which

might occur if the system was not properly purged of air

before start-up.

1.

After the transmission components have been properly

installed, fill the servo pump housing at least half full

with filtered system oil. Connect all hydraulic lines and

check to be sure they are tight.

2.

Install and adjust all control linkage.

3.

Fill the reservoir with an approved oil that has been fil-

tered through a 10 micron filter. Refer to Eaton Hydrau-

lics Technical Data sheet number 3-401 titled Hydraulic

Fluid Recommendations.

4.

Gasoline or L.P. engines: remove the coil wire and turn

the engine over for 15 seconds. Diesel engines: shut off

the fuel flow to the injectors and turn the engine over

for 15 seconds.

5.

Replace the coil wire or return the fuel flow to the injec-

tors. Place the transmission unit in the neutral position,

start the engine and run it at a low idle. The charge

pump should immediately pick up oil and fill the system.

If there is no indication of fill in 30 seconds, stop engine

and determine the cause.

6.

After the system starts to show signs of fill, slowly move

pump swashplate to a slight cam angle. Continue to

operate system slowly with no load on motors until sys-

tem responds fully.

7.

Check fluid level in the reservoir and refill if necessary to

the proper level with an approved filtered oil.

8.

Check all line connections for leaks and tighten if neces-

sary.

9.

The machine is now ready to be put into operation.

10.

Frequent filter changes are recommended for the first

two changes after placing the machine back into opera-

tion. Change the first filter in 3-5 hours and the second

at approximately 50 hours. Routinely scheduled filter

changes are recommended for maximum life of the

hydraulic system.

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......