SECTION 3 - CHASSIS & TURNTABLE

3-32

3121160

3.9

DRIVE MOTOR (SN 0300138447 THROUGH

0300185827)

Description

The drive motors are low to medium power, two-position axial

piston motors incorporating an integral servo piston. They are

designed for operation in both open and closed circuit appli-

cations. The standard control is a direct acting single line

hydraulic control. The integral servo piston controls motor dis-

placement.

The motors are spring biased to maximum displacement and

hydraulically sh.ifted to minimum displacement. Minimum

and maximum displacement can be set with fixed internal

stops. The large diameter servo piston allows smooth accelera-

tion and deceleration with relatively large circuit orificing.

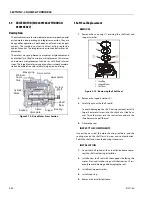

Shaft Seal Replacement

REMOVAL

1.

Remove the snap ring (1) retaining the shaft seal and

support washer.

2.

Remove the support washer (2).

3.

Carefully pry out the shaft seal (3).

To avoid damaging the shaft during removal, install a

large sheet metal screw into the chuck of a slide ham-

mer. Drive the screw into the seal surface and use the

slide hammer to pull the seal.

4.

Discard the seal.

INSPECT THE COMPONENTS

Inspect the new seal, the motor housing seal bore, and the

sealing area on the shaft for rust, wear, and contamination.

Polish the shaft and clean the housing if necessary.

INSTALLATION

1.

Cover the shaft splines with an installation sleeve to pro-

tect the shaft seal during installation.

2.

Install a new shaft seal with the cupped side facing the

motor. Press seal into housing until it bottoms out. Press

evenly to avoid binding and damaging the seal.

3.

Install seal support washer.

4.

Install snap ring.

5.

Remove the installation sleeve.

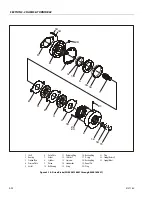

Bias spring

Servo piston

Swashplate

Output

Shaft

Piston

Slipper

Cylinder

Block

Endcap

Shaft

Seal

Bearing

Minimum

Angle

Stop

Valve plate

Figure 3-14. Drive Motor Cross Section

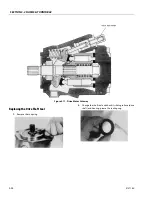

1

2

3

1.

Snap Ring

2.

Support Washer

3.

Shaft Seal

Figure 3-15. Removing the Shaft Seal

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......