SECTION 3 - CHASSIS & TURNTABLE

3121160

3-35

Disassembly

NOTE:

Removal of the endcap voids warranty.

During assembly, coat all moving parts with a film of clean

hydraulic oil. This assures that these parts will be lubricated

during start-up.

Replace all o-rings and gaskets.

It is recommended that all o-rings be replaced. Lightly

lubricate all o-rings with clean petroleum jelly prior to

assembly.

1.

Using a 11/16 in wrench remove plug (1) and (2).

2.

Using a 5/8 in hex wrench remove plug (3).

3.

Remove o-rings (4, 5, and 6).

4.

Using pliers, remove centering springs (7, 8, and 9).

5.

Remove spring retaining washers (10 and 11).

6.

Remove shift spool (12).

7.

Remove orifice poppet (13).

8.

Remove all fittings from the unit. Discard any O-rings on

the fittings.

9.

Using an 11/16 in. hex wrench, loosen the speed sensor

lock nut (14) if equipped. Then remove the speed sensor

using a Vi in. hex wrench. Units without speed sensor

have an o-ring plug (15) installed in that location;

remove it with a Va in. internal hex wrench.

10.

Using a 1/4 in. internal hex wrench, remove control line

plugs (16, 17). Discard o-rings. Using a 3 mm hex

wrench, remove cavity plug (18, if equipped with two-

line control) from X2 cavity.

11.

Using a 5/16 in. internal hex wrench, remove drain plugs

(19, 20). Discard o-rings.

12.

Using a 9/16 in. internal hex wrench, remove work port

plugs (21, if equipped with axial ports). Discard o-rings.

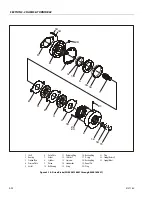

5

3

7

13

2

6

9

11

1

4

8

10

12

1.

Plug

2.

Plug

3.

Plug

4.

O-ring

5.

O-ring

6.

O-ring

7.

Spring

8.

Spring

9.

Spring

10. Washer

11. Washer

12. Shift Spool

13. Orifice Poppet

Figure 3-17. Loop Flushing Spool

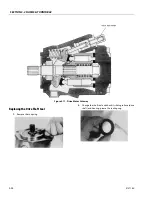

15

20

16

16

19

17

18

21

14

14. Lock Nut

15. O-ring Plug

16. Control Line Plug

17. Control Line Plug

18. Cavity Plug

19. Drain Plug

20. Drain Plug

21. Work Port Plug

Figure 3-18. Plugs, Fittings, and Speed Sensor

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......