SECTION 3 - COMPONENT SERVICING

31215861

3-3

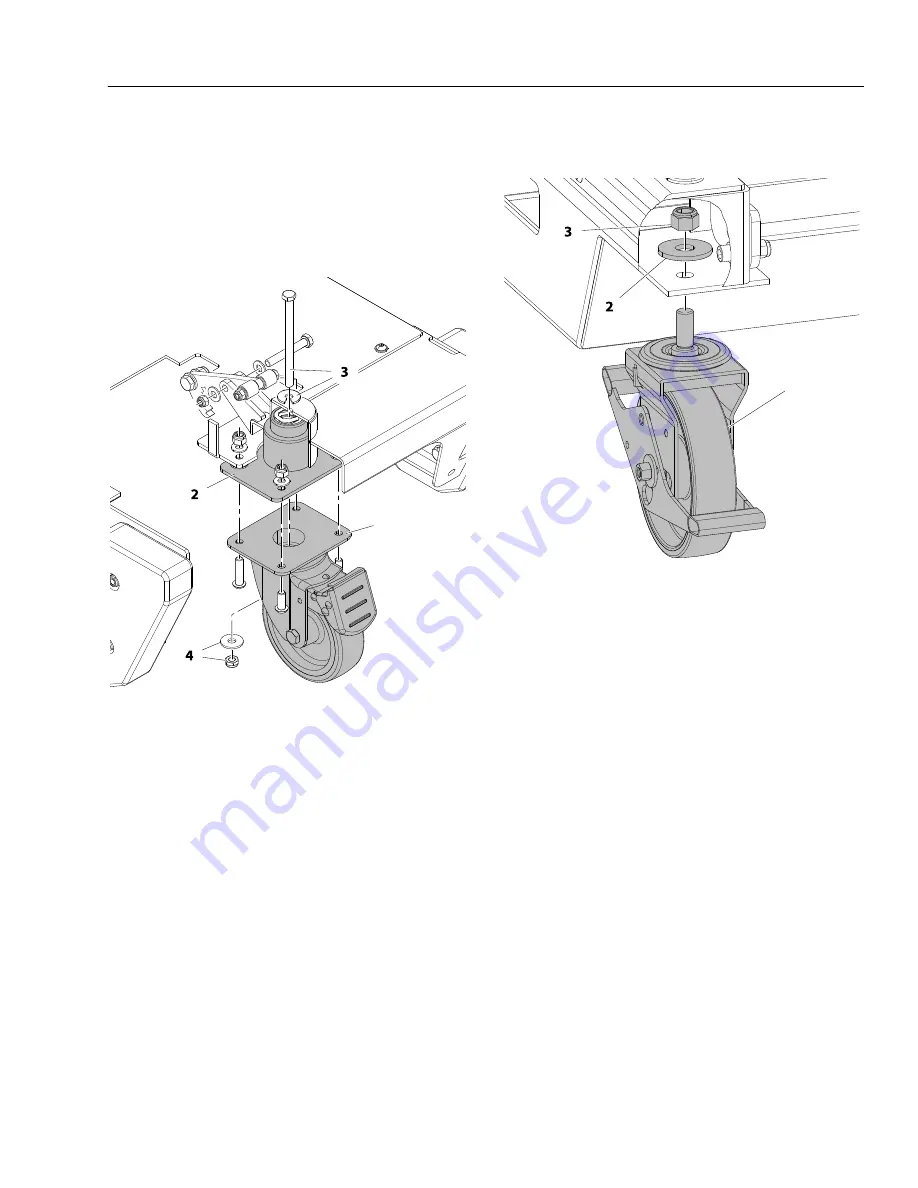

3.4 CASTOR WHEEL ASSEMBLY

In order to ensure the castors are maintained in serviceable and

safe condition, regular inspection is required, especially where

arduous conditions are known to be involved or there is suspi

-

cion of misuse or abuse.

EcoLift50

1.

Use suitable lifting equipment to raise and support

the front of the machine to allow removal of the castor

wheel.

2.

Be certain the castor is in the down position removing

the tension from the internal spring.

3.

Using correct size wrench or socket hold the mount

-

ing bolt head on the top of the chassis frame housing

and remove the locking nut and washer on the bot

-

tom of the castor wheel assembly inside the castor

wheel frame.

4.

Slide castor and mount assembly out bottom of

frame.

Install in reverse order using the above steps.

EcoLift70

1.

Using suitable lifting equipment raise the front of the

machine to allow removal of the castor wheel.

2.

Using correct size wrench or socket remove the

attaching nut on the top of the castor wheel assembly

inside the frame.

3.

Slide castor assembly out bottom of frame.

Install in reverse order using the above steps.

1.

Castor Wheel Assembly

2.

Spring Mount

3.

Mounting Bolt and Washer

4.

Locking Nut and Washer

1

1.

Castor Wheel Assembly

2.

Washer

3.

Locking Nut

1

Go

to

Discount-Equipment.com

to

order

your

parts