TABLE OF CONTENTS

System Schematic...........................................................................................................................Page 2

Representative Performance Data......................................................................................................Page 2

Description and Operation of Power Brake Valve......................................................................Pages 3, 4 & 5

External Dimensional Views...............................................................................................................Page 5

Installation of Power Brake Valve........................................................................................................Page 5

Cross Sectional Views of Three Power Brake Valve Designs.................................................................Page 6

Specification Chart...........................................................................................................................Page 7

Primary Cup Design..................................................................................................................Pages 8 & 9

Teflon Seal Design.................................................................................................................Pages 10 & 11

Sliding Piston Design.............................................................................................................Pages 12 & 13

Service Diagnosis...........................................................................................................................Page 14

Bleeding...............................................................................................................................Pages 14 & 15

PERFORMANCE DATA (Typical)

Flow capacity.................................................................................See Specification Chart (page 7)

System pressure..........................................................................................................0 - 2000 psi

Brake line pressure.........................................................................See Specification Chart (page 7)

Master cylinder, capacity......................................................................................................3.1 in.

3

Push rod travel with power...........................................................................................0.2” (approx.)

Push rod force with power.................................................... .340 lbs. at 1500 psi brake line pressure

225 lbs. at 250 psi brake line pressure (Model 06-460-652 only)

Push rod travel without power...................................................................................1.844” (approx.)

Push rod force without power..............................................................................1500 lbs. at 725 psi

518 lbs. at 250 psi (Model 06-460-652 only)

NOTE: Brake system rubber parts (Buna-N) must be compatible with mineral based hydraulic oil.

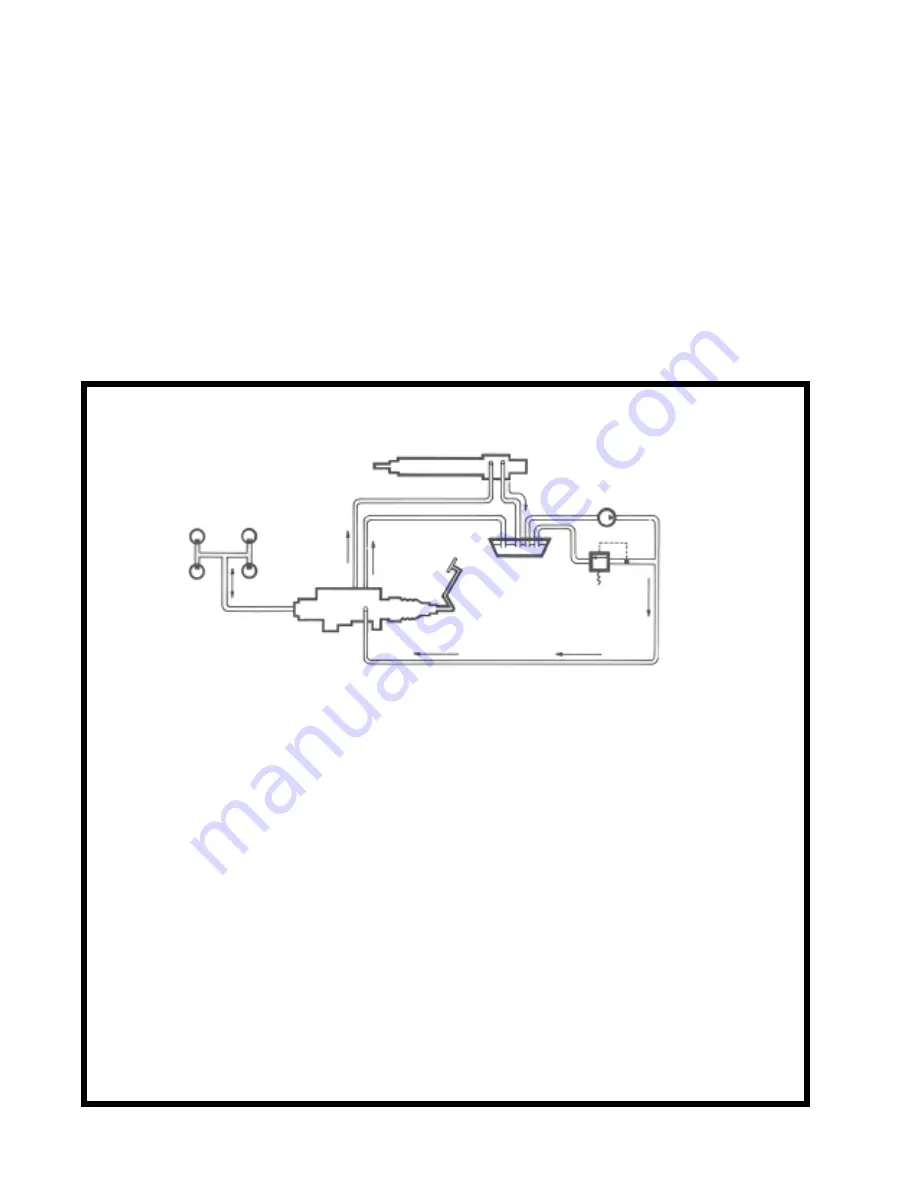

SYSTEM SCHEMATIC (TYPICAL)

FIGURE 1

(2)

BRAKE

POWER

STEERING

CYLINDER

RESERVOIR

RETURN

LINE

FLOW-

THRU

PRESSURE

MICO

BRAKE

VALVE

Summary of Contents for GRADALL 522

Page 2: ...Courtesy of Crane Market...

Page 4: ...Courtesy of Crane Market...

Page 5: ...Courtesy of Crane Market...

Page 6: ...Courtesy of Crane Market...

Page 7: ...Courtesy of Crane Market...

Page 8: ...Courtesy of Crane Market...

Page 9: ...Courtesy of Crane Market...

Page 10: ...Courtesy of Crane Market...

Page 11: ...Courtesy of Crane Market...

Page 12: ...Courtesy of Crane Market...

Page 13: ...Courtesy of Crane Market...

Page 14: ...Courtesy of Crane Market...

Page 15: ...Courtesy of Crane Market...

Page 16: ...Courtesy of Crane Market...

Page 17: ...Courtesy of Crane Market...

Page 18: ...Courtesy of Crane Market...

Page 19: ...Courtesy of Crane Market...

Page 20: ...Courtesy of Crane Market...

Page 21: ...Courtesy of Crane Market...

Page 22: ...Courtesy of Crane Market...

Page 23: ...Courtesy of Crane Market...

Page 24: ...Courtesy of Crane Market...

Page 25: ...Courtesy of Crane Market...

Page 26: ...Courtesy of Crane Market...

Page 27: ...Courtesy of Crane Market...

Page 28: ...Courtesy of Crane Market...

Page 29: ...Courtesy of Crane Market...

Page 30: ...Courtesy of Crane Market...

Page 31: ...Courtesy of Crane Market...

Page 32: ...Courtesy of Crane Market...

Page 33: ...Courtesy of Crane Market...

Page 34: ...Courtesy of Crane Market...

Page 35: ...Courtesy of Crane Market...

Page 36: ...Courtesy of Crane Market...

Page 37: ...Courtesy of Crane Market...

Page 38: ...Courtesy of Crane Market...

Page 39: ...Courtesy of Crane Market...

Page 40: ...Courtesy of Crane Market...

Page 41: ...Courtesy of Crane Market...

Page 42: ...Courtesy of Crane Market...

Page 43: ...Courtesy of Crane Market...

Page 44: ...Courtesy of Crane Market...

Page 45: ...Courtesy of Crane Market...

Page 46: ...Courtesy of Crane Market...

Page 47: ...Courtesy of Crane Market...

Page 48: ...Courtesy of Crane Market...

Page 49: ...Courtesy of Crane Market...

Page 50: ...Courtesy of Crane Market...

Page 51: ...Courtesy of Crane Market...

Page 52: ...Courtesy of Crane Market...

Page 53: ...Courtesy of Crane Market...

Page 54: ...Courtesy of Crane Market...

Page 55: ...Courtesy of Crane Market...

Page 56: ...Courtesy of Crane Market...

Page 73: ...Courtesy of Crane Market...

Page 74: ...Courtesy of Crane Market...

Page 75: ...Courtesy of Crane Market...

Page 76: ...Courtesy of Crane Market...

Page 77: ...Courtesy of Crane Market...

Page 79: ...I PRA 352 Trumpet Variation No 1 47 Courtesy of Crane Market...

Page 87: ...IX PROA 352 382 Courtesy of Crane Market...

Page 150: ...Courtesy of Crane Market...

Page 151: ...Courtesy of Crane Market...

Page 152: ...Courtesy of Crane Market...

Page 153: ...Courtesy of Crane Market...

Page 154: ...Courtesy of Crane Market...

Page 155: ...Courtesy of Crane Market...

Page 156: ...Courtesy of Crane Market...

Page 157: ...Courtesy of Crane Market...

Page 158: ...Courtesy of Crane Market...

Page 159: ...Courtesy of Crane Market...

Page 160: ...Courtesy of Crane Market...

Page 161: ...Courtesy of Crane Market...

Page 162: ...Courtesy of Crane Market...

Page 163: ...Courtesy of Crane Market...

Page 164: ...Courtesy of Crane Market...

Page 165: ...Courtesy of Crane Market...

Page 166: ...Courtesy of Crane Market...

Page 167: ...Courtesy of Crane Market...

Page 168: ...Courtesy of Crane Market...

Page 169: ...Courtesy of Crane Market...

Page 170: ...Courtesy of Crane Market...

Page 171: ...Courtesy of Crane Market...

Page 172: ...Courtesy of Crane Market...

Page 173: ...Courtesy of Crane Market...

Page 174: ...Courtesy of Crane Market...

Page 175: ...Courtesy of Crane Market...

Page 176: ...Courtesy of Crane Market...

Page 177: ...Courtesy of Crane Market...

Page 178: ...Courtesy of Crane Market...

Page 179: ...Courtesy of Crane Market...

Page 180: ...Courtesy of Crane Market...

Page 181: ...Courtesy of Crane Market...

Page 182: ...Courtesy of Crane Market...

Page 183: ...Courtesy of Crane Market...

Page 184: ...Courtesy of Crane Market...

Page 185: ...Courtesy of Crane Market...

Page 186: ...Courtesy of Crane Market...

Page 187: ...Courtesy of Crane Market...

Page 188: ...Courtesy of Crane Market...

Page 189: ...Courtesy of Crane Market...

Page 190: ...Courtesy of Crane Market...

Page 191: ...Courtesy of Crane Market...

Page 192: ...Courtesy of Crane Market...

Page 193: ...Courtesy of Crane Market...

Page 194: ...Courtesy of Crane Market...

Page 195: ...Courtesy of Crane Market...

Page 196: ...Courtesy of Crane Market...

Page 197: ...Courtesy of Crane Market...

Page 198: ...Courtesy of Crane Market...

Page 199: ...Courtesy of Crane Market...

Page 200: ...Courtesy of Crane Market...

Page 201: ...Courtesy of Crane Market...

Page 202: ...Courtesy of Crane Market...

Page 203: ...Courtesy of Crane Market...

Page 204: ...Courtesy of Crane Market...

Page 205: ...Courtesy of Crane Market...

Page 206: ...Courtesy of Crane Market...

Page 207: ...Courtesy of Crane Market...

Page 208: ...Courtesy of Crane Market...

Page 209: ...Courtesy of Crane Market...

Page 210: ...Courtesy of Crane Market...

Page 211: ...Courtesy of Crane Market...

Page 212: ...Courtesy of Crane Market...

Page 213: ...Courtesy of Crane Market...

Page 214: ...Courtesy of Crane Market...

Page 215: ...Courtesy of Crane Market...

Page 216: ...Courtesy of Crane Market...

Page 217: ...Courtesy of Crane Market...

Page 218: ...Courtesy of Crane Market...

Page 219: ...Courtesy of Crane Market...

Page 220: ...Courtesy of Crane Market...

Page 221: ...Courtesy of Crane Market...

Page 222: ...Courtesy of Crane Market...

Page 223: ...Courtesy of Crane Market...

Page 224: ...Courtesy of Crane Market...

Page 225: ...Courtesy of Crane Market...

Page 226: ...Courtesy of Crane Market...

Page 227: ...Courtesy of Crane Market...

Page 228: ...Courtesy of Crane Market...

Page 229: ...Courtesy of Crane Market...

Page 230: ...Courtesy of Crane Market...

Page 231: ...Courtesy of Crane Market...

Page 232: ...Courtesy of Crane Market...

Page 233: ...Courtesy of Crane Market...

Page 234: ...Courtesy of Crane Market...

Page 235: ...Courtesy of Crane Market...

Page 236: ...Courtesy of Crane Market...

Page 237: ...Courtesy of Crane Market...

Page 238: ...Courtesy of Crane Market...

Page 239: ...Courtesy of Crane Market...

Page 240: ...Courtesy of Crane Market...

Page 241: ...Courtesy of Crane Market...

Page 242: ...Courtesy of Crane Market...

Page 243: ...Courtesy of Crane Market...

Page 244: ...Courtesy of Crane Market...

Page 245: ...Courtesy of Crane Market...

Page 246: ...Courtesy of Crane Market...

Page 247: ...Courtesy of Crane Market...

Page 248: ...Courtesy of Crane Market...

Page 249: ...Courtesy of Crane Market...

Page 250: ...Courtesy of Crane Market...

Page 251: ...Courtesy of Crane Market...

Page 252: ...Courtesy of Crane Market...

Page 271: ...Courtesy of Crane Market...

Page 273: ...Courtesy of Crane Market...

Page 274: ...Courtesy of Crane Market...

Page 275: ...Courtesy of Crane Market...

Page 276: ...Courtesy of Crane Market...

Page 277: ...Courtesy of Crane Market...

Page 278: ...Courtesy of Crane Market...

Page 279: ...Courtesy of Crane Market...

Page 280: ...Courtesy of Crane Market...

Page 281: ...Courtesy of Crane Market...

Page 282: ...Courtesy of Crane Market...

Page 283: ...Courtesy of Crane Market...

Page 284: ...Courtesy of Crane Market...