SECTION 2 - PREPARATION AND INSPECTION

1001070465

LIFTPOD by JLG

2-4

Pre-Start Inspection

The Pre-Start Inspection should include each of the following:

1. Cleanliness

– Check all surfaces for leakage, debris or

foreign objects.

2. Decals and Placards

– Check all for cleanliness and

legibility. Make sure none of the decals and placards are

missing. Make sure all illegible decals and placards are

cleaned or replaced. (Reference Section 5.2, Decal

Installation).

3. Operation, Safety, Service & Maintenance Manual

–

Make sure a copy of the Operation, Safety, Service &

Maintenance Manual is enclosed in the weather resis-

tant storage container.

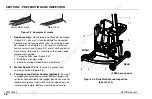

4. Assembly

– The machine must be fully assembled in

accordance with Section 3.3.

5. Walk-Around Inspection

6. Powerpack

– Charge as required (Section 3.4).

7. Function Check

– Once the Walk-Around Inspection is

complete, perform a function check of all systems in an

area free of overhead and ground level obstructions.

Refer to Section 2.4 for more specific instructions.

2.3

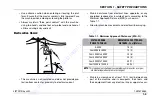

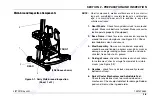

DAILY WALK-AROUND INSPECTION

Begin the Walk-Around Inspection at item one (1) as noted on the

diagram Figure 2-1. Continue around machine checking each item

in sequence for the conditions listed in the following check list.

TO AVOID POSSIBLE INJURY, BE SURE DIRECTION SELECTOR IS IN THE

“OFF” POSITION DURING WALK-AROUND INSPECTION.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE BEEN

CORRECTED.

NOTE:

Do not overlook visual inspection of the base frame

underside. Check this area for objects, debris, corrosion

and cracks.

NOTE:

The mast and carriage components should be clean and

free from oil, grease and dirt. Do not lubricate mast or car-

riage components, especially brake shoes.

Go to Discount-Equipment.com

to order your parts