SECTION 3 - CHASSIS & TURNTABLE

3121200

3-91

12.

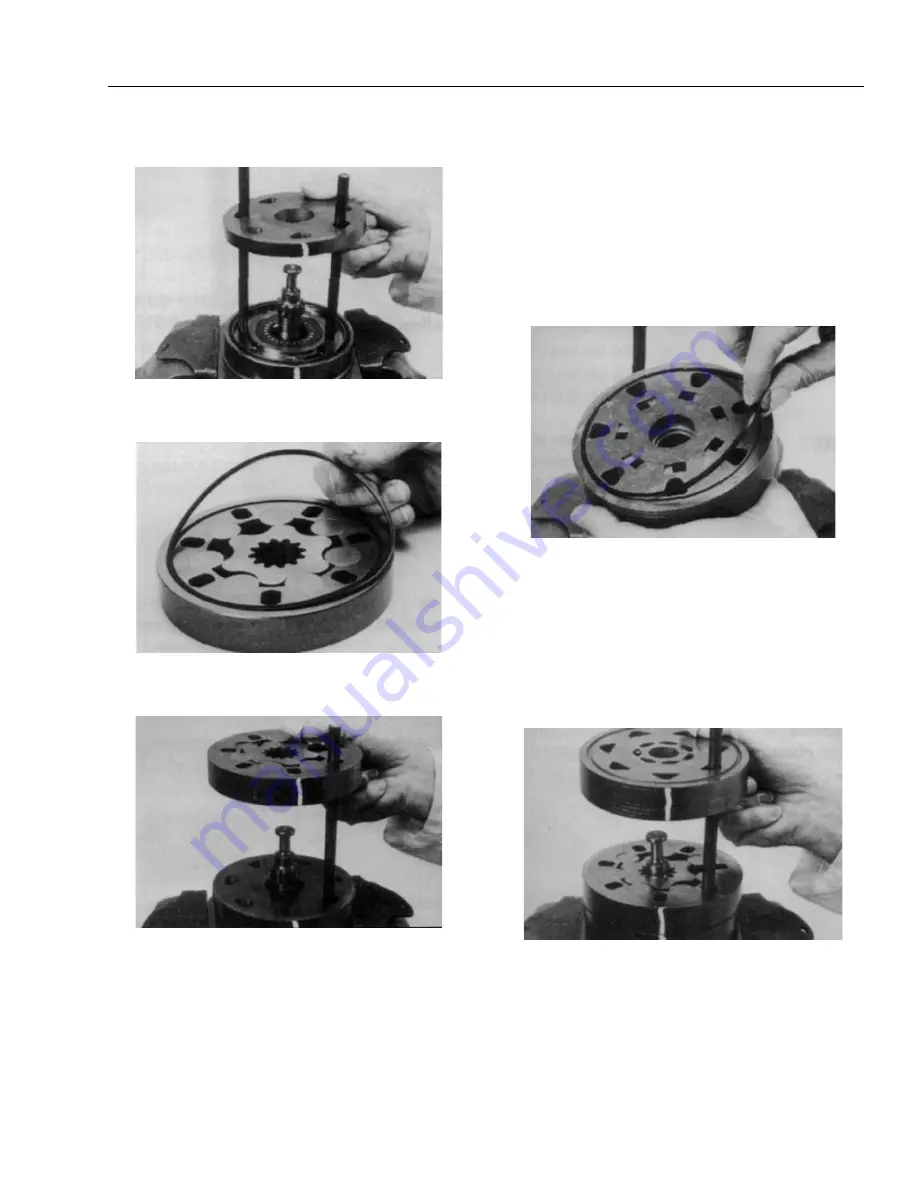

Assemble wear plate (9) over the drive link (10) and

alignment studs onto the housing (18).

13.

Apply a small amount of clean grease to a new seal ring

(4) and assemble it into the seal ring groove on the wear

plate side of the rotor set stator.

14.

Install the assembled rotor set (8) onto wear plate (9)

with rotor counter bore and seal ring side down and the

splines into mesh with the drive link splines.

NOTE:

It may be necessary to turn one alignment stud out of the

housing (18) temporarily to assemble rotor set (8) or mani-

fold (7) over the drive link.

NOTE:

If necessary, go to the appropriate, “Rotor Set Component

Assembly Procedure.”

NOTE:

The rotor set rotor counter bore side must be down against

wear plate for drive link clearance and to maintain the

original rotor-drive link spline contact. A rotor set without

a counter bore and that was not etched before disassembly

can be reinstalled using the drive link spline pattern on the

rotor splines if apparent, to determine which side was

down. The rotor set seal ring groove faces toward the wear

plate (9).

15.

Apply clean grease to a

new

seal ring (4) and assemble it

in the seal ring groove in the rotor set contact side of

manifold (7).

NOTE:

The manifold (7) is made up of several plates bonded

together permanently to form an integral component. The

manifold surface that must contact the rotor set has it’s

series of irregular shaped cavities on the largest circumfer-

ence or circle around the inside diameter. The polished

impression left on the manifold by the rotor set is another

indication of which surface must contact the rotor set.

16.

Assemble the manifold (7) over the alignment studs and

drive link (10) and onto the rotor set. Be sure the correct

manifold surface is against the rotor set.

Summary of Contents for T500J

Page 1: ...Service and Maintenance Manual Model T500J PN 3121200 July 25 2018 Rev I AS NZS...

Page 2: ......

Page 16: ...xii 3121200 LIST OF TABLES TABLE NO TITLE PAGE NO This page left blank intentionally...

Page 36: ...SECTION 2 GENERAL 2 8 3121200 NOTES...

Page 143: ...SECTION 3 CHASSIS TURNTABLE 3121200 3 107 Figure 3 45 Battery Charger Schematic...

Page 234: ...SECTION 5 BASIC HYDRAULIC INFORMATION SCHEMATICS 5 60 3121200 NOTES...

Page 246: ...SECTION 6 JLG CONTROL SYSTEM 6 12 3121200 Figure 6 5 System Test Flow Chart Platform Tests...

Page 304: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 32 3121200 NOTES...

Page 305: ......