SECTION 3 - CHASSIS & TURNTABLE

3-60

3121200

Wear Tolerance

1.

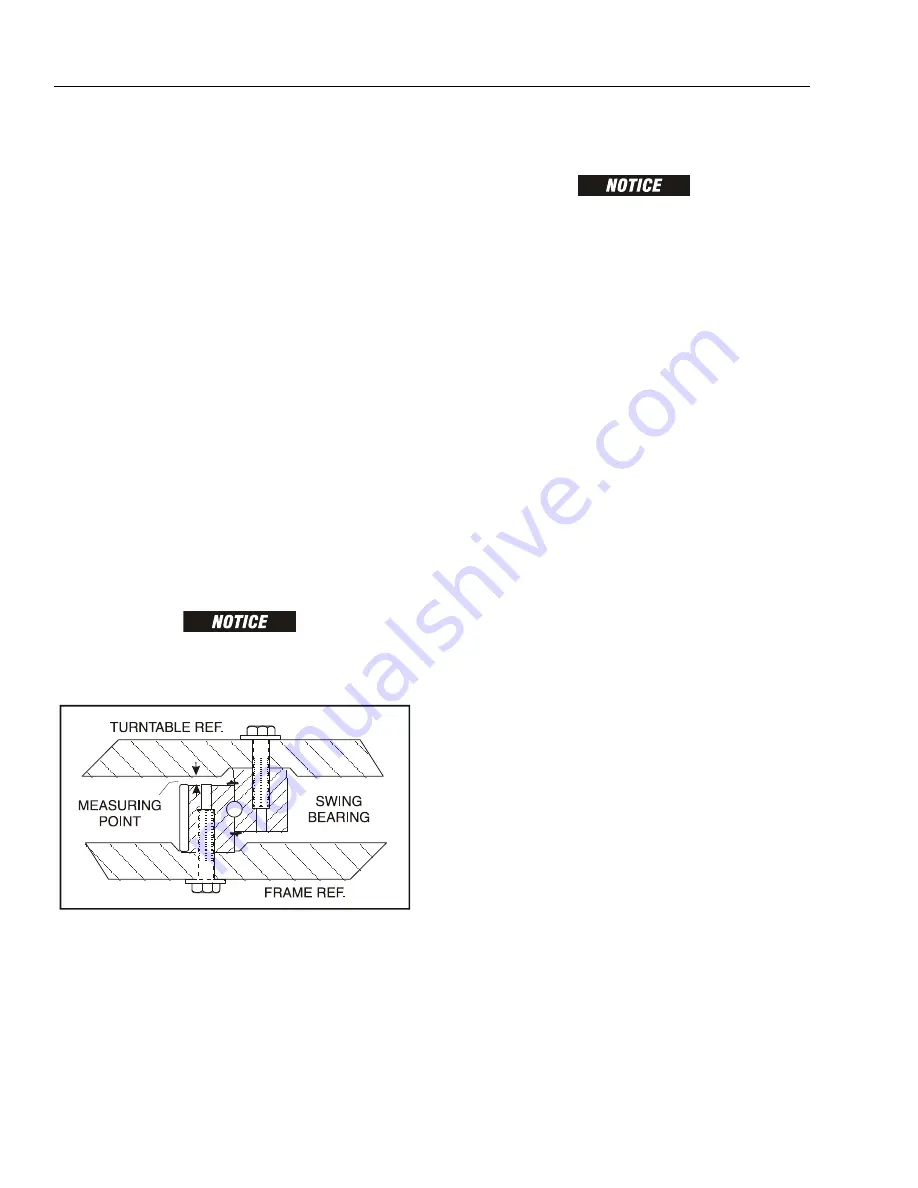

From the underside of the machine, at rear center, with

the main boom fully elevated and fully retracted, using a

magnetic base dial indicator, measure and record the

distance between the swing bearing and turntable. See

Figure 3-28., Swing Bearing Tolerance Measuring Point

2.

At the same point, with the main boom at horizontal

and fully extended, using a magnetic base dial indicator,

measure and record the distance between the swing

bearing and turntable. See Figure 3-28., Swing Bearing

Tolerance Measuring Point.

3.

If a difference greater than 0.057 in. (1.40 mm) is deter-

mined, the swing bearing should be replaced.

4.

If a difference less than 0.057 in. (1.40 mm) is deter-

mined, and any of the following conditions exist, the

bearing should be removed, disassembled, and

inspected for the following:

a.

Metal particles in the grease

b.

Increased drive power required

c.

Noise

d.

Rough rotation

5.

If bearing inspection shows no defects, reassemble and

return to service.

THE SWING BEARING IS ONE OF THE MOST CRITICAL POINTS ON AN AERIAL

LIFT. IT IS HERE THAT THE STRESSES OF LIFTING ARE CONCENTRATED, AT THE

CENTER OF ROTATION. BECAUSE OF THIS, PROPER MAINTENANCE OF THE

SWING BEARING BOLTS IS A MUST FOR SAFE OPERATION.

Swing Bearing Removal

HYDRAULIC LINES AND PORTS SHOULD BE CAPPED IMMEDIATELY AFTER DIS-

CONNECTING LINES TO AVOID THE ENTRY OF CONTAMINANTS INTO THE SYS-

TEM.

1.

Remove the boom assembly. refer to Section 4.3, Boom

and Cylinder Assembly.

2.

Tag and disconnect the hydraulic lines from the fittings

on the turntable. Use a suitable container to retain any

residual hydraulic fluid. Immediately cap lines and ports.

3.

Attach suitable overhead lifting equipment to the base

of the turntable.

4.

Use a suitable tool to scribe a line on the inner race of

the swing bearing and on the underside of the turnta-

ble. This will aid in aligning the bearing upon installa-

tion. Remove the bolts and washers which attach the

turntable to the bearing inner race. Discard the bolts.

5.

Use the lifting equipment to carefully lift the complete

turntable assembly from the bearing. Ensure that no

damage occurs to the turntable, bearing or frame-

mounted components.

6.

Carefully place the turntable on a suitably supported

trestle.

7.

Use a suitable tool to scribe a line on the outer race of

the swing bearing and the frame. This line will aid in

aligning the bearing upon installation. Remove the bolts

and washers which attach the outer race of the bearing

to the frame. Discard the bolts. Use suitable lifting

equipment to remove the bearing from the frame, then

move the bearing to a clean, suitably supported work

area.

Figure 3-28. Swing Bearing Tolerance Measuring Point

Summary of Contents for T500J

Page 1: ...Service and Maintenance Manual Model T500J PN 3121200 July 25 2018 Rev I AS NZS...

Page 2: ......

Page 16: ...xii 3121200 LIST OF TABLES TABLE NO TITLE PAGE NO This page left blank intentionally...

Page 36: ...SECTION 2 GENERAL 2 8 3121200 NOTES...

Page 143: ...SECTION 3 CHASSIS TURNTABLE 3121200 3 107 Figure 3 45 Battery Charger Schematic...

Page 234: ...SECTION 5 BASIC HYDRAULIC INFORMATION SCHEMATICS 5 60 3121200 NOTES...

Page 246: ...SECTION 6 JLG CONTROL SYSTEM 6 12 3121200 Figure 6 5 System Test Flow Chart Platform Tests...

Page 304: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 32 3121200 NOTES...

Page 305: ......