SECTION 3 - CHASSIS & TURNTABLE

3-18

3121200

WHEEL CYLINDERS

Inspect for leaks and smooth operation. Clean with brake

cleaner and flush with fresh brake fluid. Hone or replace as

necessary.

BRAKE LINES

Check for cracks, kinks, or blockage. Flush with fresh brake

fluid. Bleed system to remove all air. Replace as necessary.

SHOES AND LININGS

Inspect visually. Replace if the lining is worn to within 1/16"

(1.6 mm) or less, contaminated with grease or oil, or abnor-

mally scored or gouged. When replacement is necessary, it is

important to replace both shoes on each brake and both

brakes of the same axle to maintain balance in the braking sys-

tem.

After replacement of the brake shoes and linings, the brakes

must be re-burnished to seat in the new components. This

should be done by applying the brakes 20 to 30 times from an

initial speed of 40 mph, slowing the vehicle to 20 mph. Allow

ample time for the brakes to cool between applications. This

procedure allows the brake shoes to seat in to the drum sur-

face.

HARDWARE

Check all hardware. Check shoe retractor spring, hold down

springs, and adjuster springs for stretch or wear. Replace as

required.

DRUMS

Check drums for scoring, cracking, or uneven wear. Turn drum

smooth only if under maximum diameter. Replace as neces-

sary.

3.7

TIRES & WHEELS

Tire Inflation

Tire pressure is the most important factor in tire life. Inflation

pressure should be as recommended and stated on the side-

wall of the tire. Pressure should be checked cold before opera-

tion. Do not bleed air from tires when they are hot. Check

inflation pressure weekly during use to insure the maximum

tire life and tread wear.

Tire Wear

Inspect tires periodically for wear or damage. Tires with less

than 1/16" (2 mm) tread depth or visible wear bands require

replacement.

A bubble, cut or bulge in a sidewall can result in a tire blowout.

Inspect both sidewalls of each tire for any bubble, cut or bulge;

and replace a damaged tire before towing the trailer.

WORN, DAMAGED OR UNDER-INFLATED TIRES CAN CAUSE LOSS OF CONTROL,

RESULTING IN DAMAGE, SERIOUS INJURY OR DEATH. INSPECT TIRES BEFORE

EACH TOW.

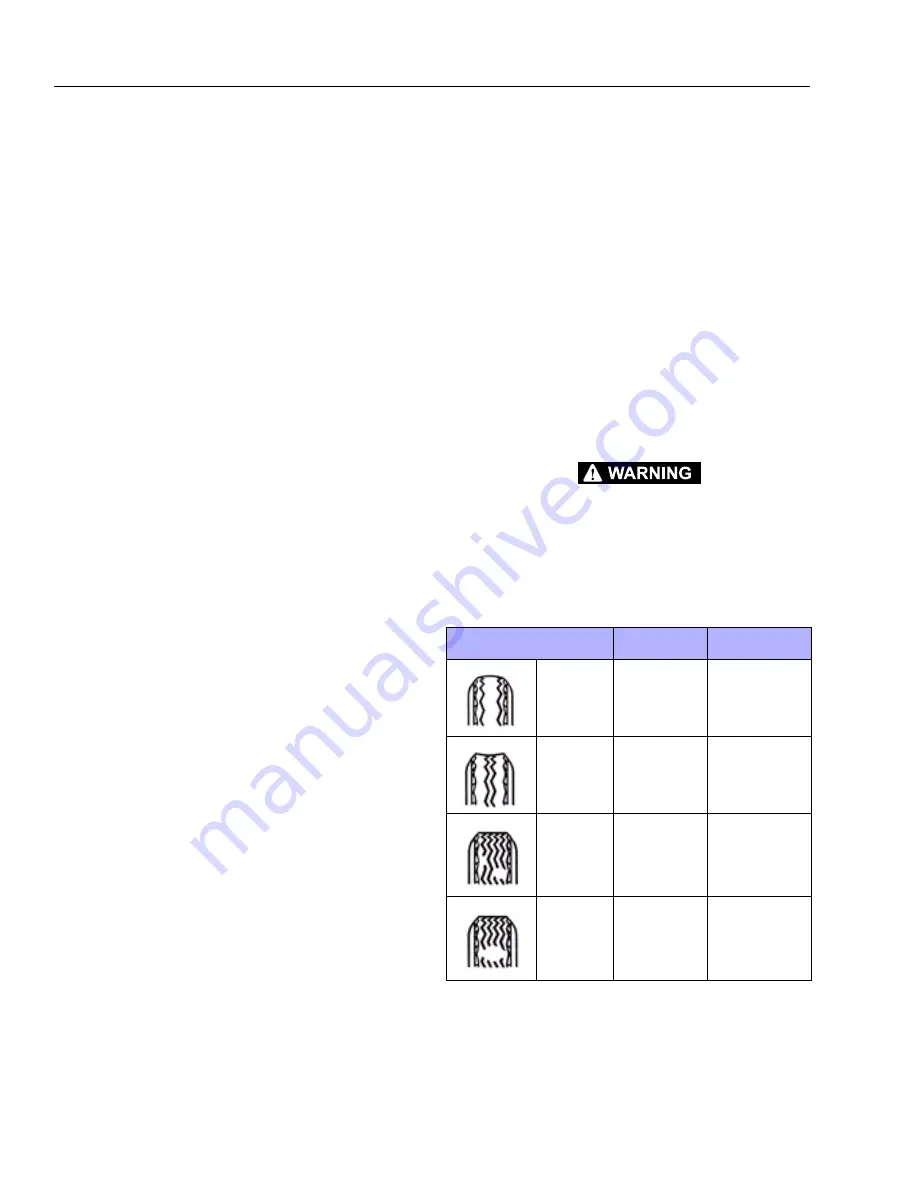

The following tire wear diagnostic chart will help you pinpoint

the causes and solution of tire wear problems.

Table 3-2. Tire Wear

Wear Pattern

Cause

Action

Center Wear

Over Inflation

Adjust Pressure to

value specified in

Section 7

Edge Wear

Under Inflation

Adjust Pressure to

value specified in

Section 7

Cupping

Out of balance

Check bearing

adjustment and bal-

ance tires

Flat Spots

Wheel lockup and

tire

skidding

Avoid sudden stops

when possible and

adjust brakes.

Summary of Contents for T500J

Page 1: ...Service and Maintenance Manual Model T500J PN 3121200 July 25 2018 Rev I AS NZS...

Page 2: ......

Page 16: ...xii 3121200 LIST OF TABLES TABLE NO TITLE PAGE NO This page left blank intentionally...

Page 36: ...SECTION 2 GENERAL 2 8 3121200 NOTES...

Page 143: ...SECTION 3 CHASSIS TURNTABLE 3121200 3 107 Figure 3 45 Battery Charger Schematic...

Page 234: ...SECTION 5 BASIC HYDRAULIC INFORMATION SCHEMATICS 5 60 3121200 NOTES...

Page 246: ...SECTION 6 JLG CONTROL SYSTEM 6 12 3121200 Figure 6 5 System Test Flow Chart Platform Tests...

Page 304: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 32 3121200 NOTES...

Page 305: ......