Models

Revision 03-2012

126

Toucan 1210

Toucan 1310

SERVICE - MAINTENANCE

7

7

Grease nipple

MIN

MAX

LOCATION

LUBRICANT TYPE

See table

LUBRICANT INTERVAL

LUBRICANT

QUANTITY

APPLICATION

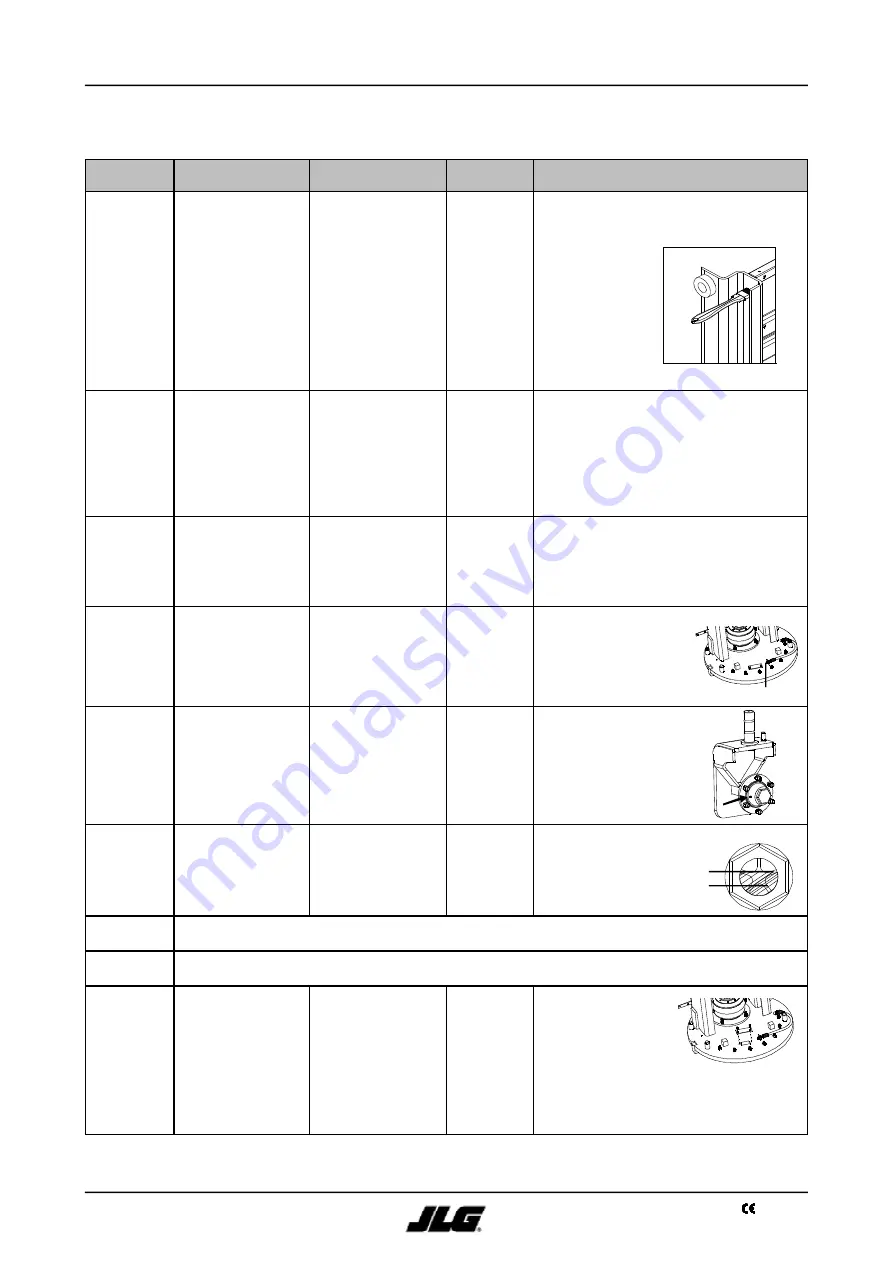

1. Mast profiles

B

Every 125 hours of

operation or each time the

machine is cleaned or more

often if the platform is used

or stored in a dusty or

corrosive environment.

N/A

1. Clean the inside of the profile to remove the old

grease

2. Lubricate the inside of the profile using a brush

3. Cycle the mast and lubricate again

The lubricant can be applied manually with a brush or

by spraying.

Apply the lubricant :

- Longitudinally = in areas where the joints are under

small load to facilitate penetration of the lubricant

- Transversally = to enable the lubricant to get to the

joint.

3. Telescope

B

Every

125

jours

of

operation

N/A

1- Clean the telescope tube to remove the old grease

(telescope extended).

2 - Lubricate the 4 faces of the tube with a paint brush.

3 - Retract / Extend the telescope a few times. Clean

the excedent.

4.

Turntable

bearing track

E

Every

250

hours

of

operation

N/A

Grease nipple on the turntable plate.

5. Wheel hubs

B

Every

250

hours

of

operation

N/A

Grease nipple on each hub

6. Main hydraulic

reservoir

A

- Check every day

- Change the oil after 1000

hours of operation or at

least every 2 years.

approx. 35 l

Fill through the return filter. Check the level

through the gauge

on the reservoir.

7. Return filter

8. Pressure filter

9.

Turntable

bearing teeth

C

Every

1000

hours

of

operation

Coat the teeth

1- Remove the cover plate

2- Apply a thick coat of grease with a brush through the

grease inspection hole. Turn the turntable to reach all

the teeth.

LUBRICATION CHART

Filter replacement intervals : after the first 50 hours of operation and every 250 hours thereafter.

Filter replacement intervals : after the first 50 hours of operation and every 250 hours thereafter.

Every 125 hours or once

every 30 days of operation

or

more

often

is

the

platform is used in a very

dusty

or

corrosive

environment.

N/A

2. Lifting chains

D