1 Device Description and Intended Use

Flow switch

1 Device Description and Intended Use

JLSO

flow switches are designed for minimum or maximum monitoring of liquid flows. The operational safety

of the supplied equipment is only guaranteed if it is operated according to its intended use (flow monitoring of

liquids). The specified limit values (see the chapter entitled “Technical Data“) should never be exceeded.

It is your responsibility to select a technology which is suitable for your specific application, to install it

correctly, to carry out tests and to maintain all the components.

Various device versions are manufactured. The respective type plate displays the version of each device.

1.1 Flow switch version VH...X

Flow switches for application in potentially explosive areas have an “X” at the end of the article number (see

the type plate). They have been subjected to an ignition hazard assessment according to DIN EN 13463-1:

2002 and do not have potential sources of ignition. They are, therefore, not subject to directive 94/9/EC.

The switching unit is a simple electrical device for connection to a certified intrinsically safe circuit according to

DIN EN 50020: 2003. The effective internal inductances and capacities are negligibly small.

The flow switch version VH...X is designed for application in explosive atmospheres. The ignition energy of the

explosive atmosphere should not be below 60µJ.

Please observe the following separation of zones:

The construction of the flow switch VH...X allows a potentially explosive atmosphere (zone 0) to exist

permanently, over a longer period or frequently within the pipework in which the paddle is located.

In normal operation, there should only be an occasional potentially explosive atmosphere (zone 1) outside the

pipework where the flow switch connection is located. A manufacturer’s declaration is available.

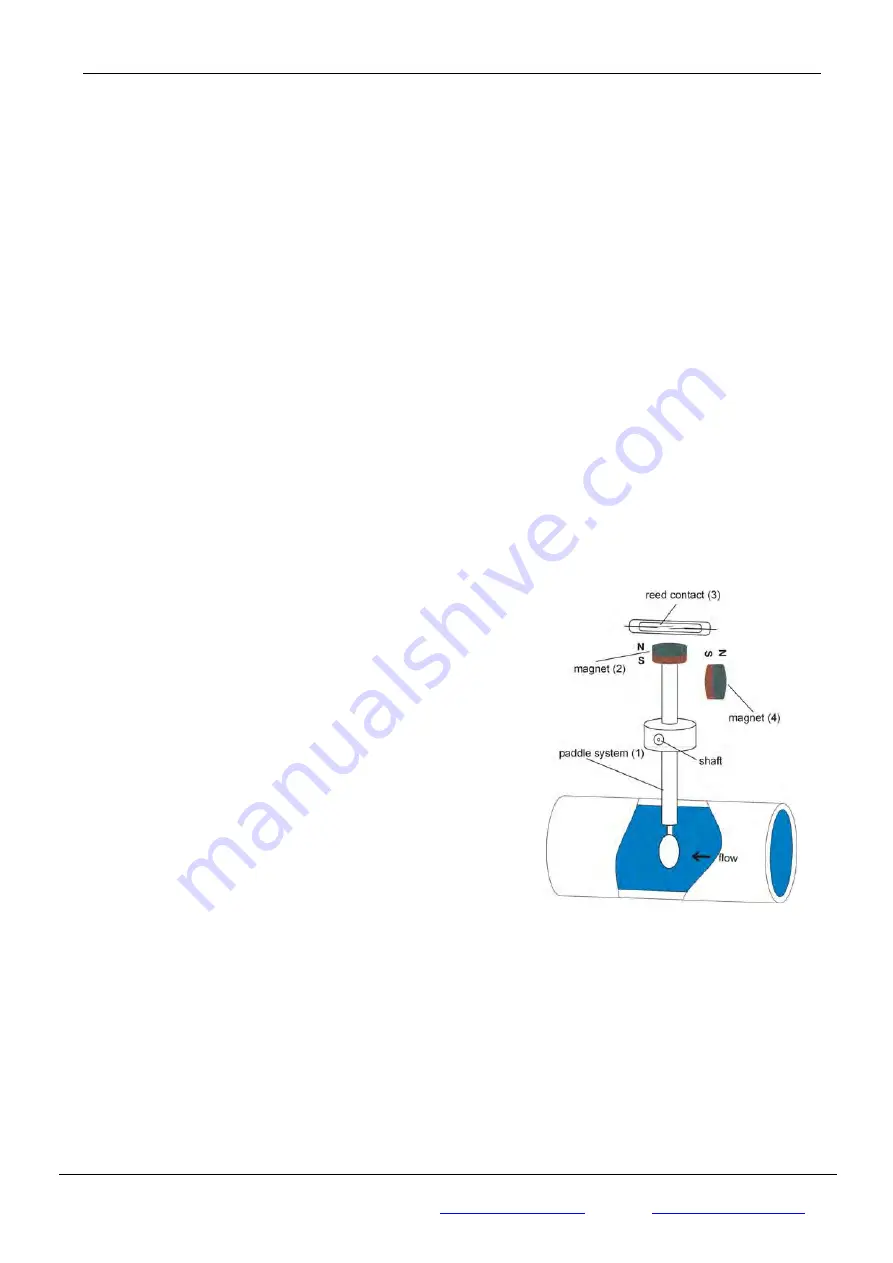

1.2 Functional principle

The flow switch consists of a paddle system (1) which has a

permanent magnet (2) located at its upper end. A reed contact

(3) is positioned outside the flow above this magnet. A second,

magnet (4) with opposite polarity is used to create a reset

force.

The paddle system is moved once it comes into contact with

the flow which is to be monitored. The magnet (2) changes its

position in relation to the reed contact (3). The contact

opens/closes depending on the contact type (see chapter 5).

As soon as the flow is interrupted, the paddle returns to its

original position and the reed contact opens/closes depending

on the contact type (see chapter 5).

Page 3 of 15

Copyright © Jlso Tec Trade GmbH

JLSO Tec Trade GmbH

In den Birken 98

Fon:

+49 (0)

6369 230 9961

info@jlso-tec-trade.de

Fax:

+49 (0)

6369 230 9963

https://jlso-tec-trade.de

Daniel

H.

Meckel

D-66999

Hinterweidenthal