2

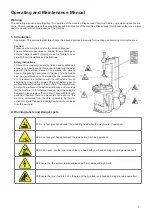

Safety warning signs

Caution

:

If the safety warning signs are folded down or have become detached, please replace them immediately with new ones!

Do not operate the machine if safety warning signs are missing or insufficiently visible. Always ensure

that the safety warning signs are clearly visible at all times and not covered by objects.

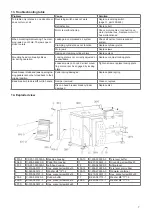

3. Technical data

Dimensions of clamping ring:

6-24“

Max. wheel diameter:

1,040 mm (41“)

Max. wheel width:

355 mm (14“)

Working pressure:

8-10 bar

Power supply:

110 V (1ph) / 220 V (1ph) / 380 V (3ph)

Motor cable for connection:

0.75/0.55/1.1 kW

Max. torque (turntable):

1,078 Nm

Overall dimensions:

96 x 76 x 93 cm

Operating noise:

75 dB

Working environment humidity:

≤ 90 %

Working environment operating temperature: 5 - 50 °C

Note:

The above clamping ring dimensions are based on iron wheel rims. Aluminium rims are thicker than iron rims, so the clamping

ring sizes mentioned here are only a reference.

4. Transportation

When transporting the machine, use the original packaging and place the machine on the markings in the packaging provided

for this purpose. The already packed machine should only be loaded and unloaded with a sufficiently powerful forklift. Fig. 1

shows the exact position at which the forks should be inserted.

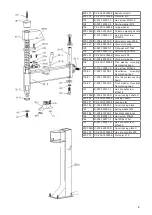

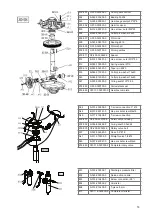

5. Unpack & checking for completeness and damage

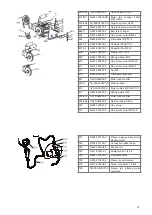

Pull out the nail attaching the plate with the top jaw. Remove the cardboard and plastic cover. Ensure that all parts listed on

the spare parts list (see item 14 of this manual) are also complete. The machine should not be operated if anything is missing

or damaged. Contact the Matthies workshop service immediately.

Fig. 1

Fig. 2

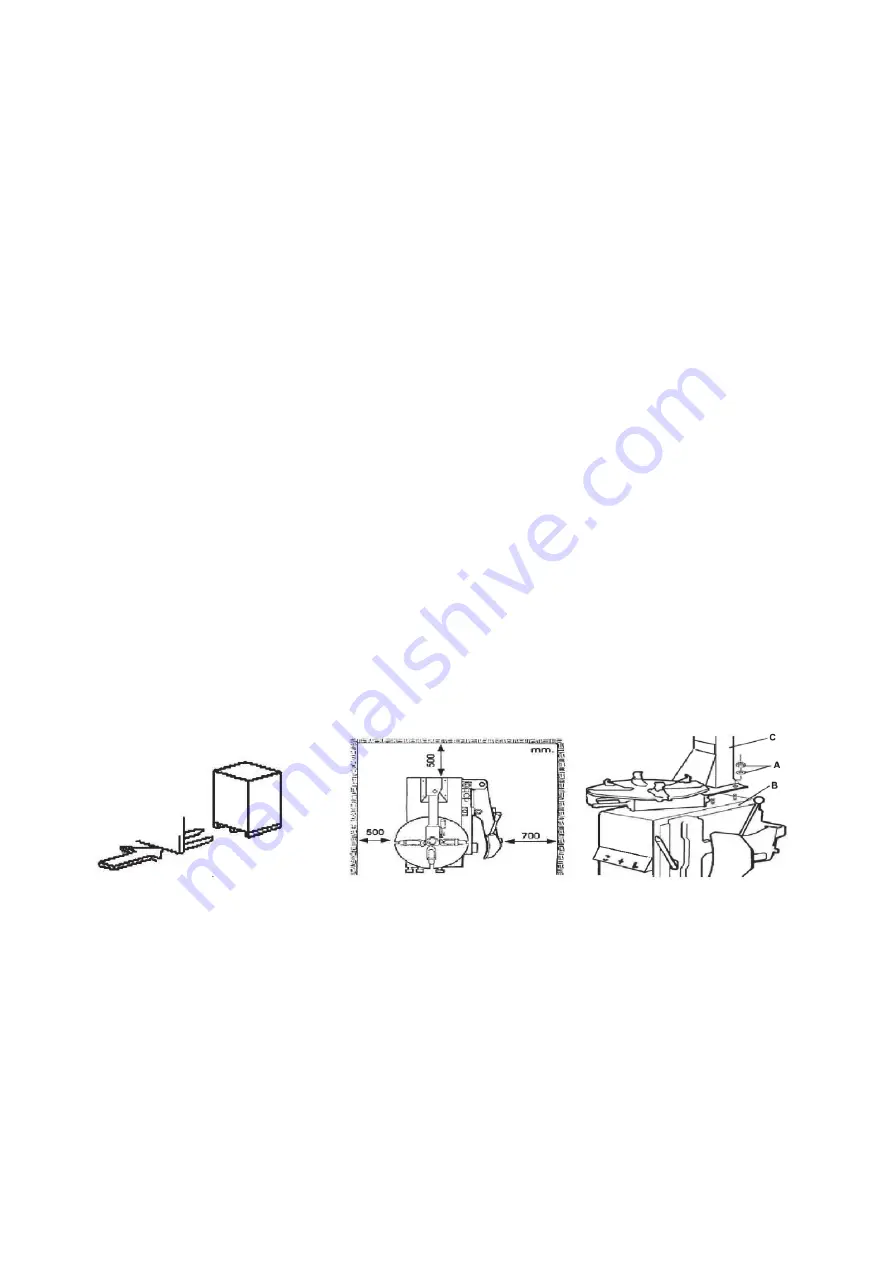

Fig. 3

6. Workplace requirements

The workplace provided for this purpose must fulfil all safety regulations. The electrical and pneumatic connections depicted in

item 8 must be available. Ensure that the workplace is adequately ventilated and cooled. In order to ensure smooth operation

of the machine, it should be set up in the designated workplace with sufficient clearance between it and the walls (as shown

in Fig. 2). If the machine is to be set up outdoors, it must be adequately protected with a roof against weather influences such

as rain and sunlight.

Warning:

Since the machine is operated with a motor, it should not be operated in an environment in which explosive materials are

located.