10/26/2005 BASIC

IF YOU HAVE ANY QUESTIONS PLEASE CALL JMR MANUFACTURING

PHONE: 805.

239.5972

FAX: 805.

239.5973

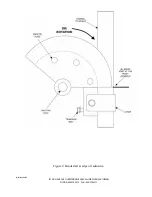

MECHANICAL BENDER

P/N MB1000

WARNING

1. Always pay close attention to what you are doing. Turn off cell phone, pager, or any other

distraction when using this machine.

2. This machine is meant to be operated by competent individuals who have a thorough

understanding of tube bending and machines in general.

3. The bender is intended to be used by a single operator. Never allow a second individual to

operate the machine while another holds tube.

4. Always wear eye protection while operating tube bender.

5. Never put your hands or other body parts into bender apparatus.

6. Never wear loose clothing while operating tube bender.

7. Always work in a clean, safe, well lit, level work area.

8. Never use the wrong size die/type die for the tube being worked.

9. Never operate the tube bender with broken, worn or damaged parts.

10. DO NOT attempt to repair and reuse any damaged bender parts.

11. User assumes all risks when using this product

.

12. This is a hand operated machine only. Use of an impact wrench on the bender high/low

drives will damage the internal drive mechanism and WILL void the warranty.

NOTE

JMR recommends that the MS1000 Mechanical Bender be mounted on the

JMR Manufacturing's MBS100 Bender Stand.

Optionally, the Mechanical Bender may also be mounted on a solid and secure work surface.