17

WARNING:

When servicing, use only

JobMate™ replacement parts. Use of any

other parts may create a safety hazard or cause damage to the tool.

Any attempt to repair or replace electrical parts on this power tool may create a safety

hazard unless repair is performed by a qualified technician.

Always order by PART NUMBER, not by key number.

Key #

Part #

Part Name

Quantity

1

321000

Rubber cap

2

2

520033

Ball bearing

1

3

163633

Switch

1

4

320024

Switch cover

1

5

234507

Cooling fan

1

6

520012

Ball bearing

1

7

110070

Stator

1

8

520007

Ball bearing

1

9

342006

Carbon brush

2

10

222806

Brush holder

2

11

314506

Brush holder support

2

12

100105

Rotor assembly

1

13

300106

Housing

1

14

500200

Tapping screw

6

15

153513

Terminal block

1

16

315001

Cord clamp

1

17

500201

Tapping screw

2

18

160205

UL plug & power cable

1

19

322004

Cord guard

1

20

315911

Vacuum adapter

1

22

315872

Dust collection sleeve

1

23

311660

Rubber foot

1

24

318017

Backing plate

1

25

5000

Tapping screw

9

26

341015

Hook & loop sheet

1

27

341014

Sponge board

1

28

318001

Sole plate

1

29

340014

Gasket ring

1

30

500206

Tapping screw

4

31

311659

Rubber foot

1

32

300106

Housing

1

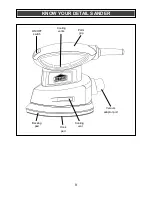

!

PARTS LIST

– MODEL 054-7236-0