9.0 INSTALLATION INSTRUCTIONS

Before Installing:

After unpacking the lift, check shipping list to ensure that you have all

required parts.

Check unit carefully for shipping damage.

Handle unit with care. Dropping could cause internal damage.

Store unit indoors or under cover to prevent rusting or pitting from

condensation.

DO NOT ATTEMPT TO RAISE THE LIFT WITHOUT SUPERSTRUCTURES

ATTACHED.

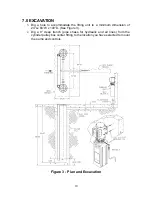

1. Attach a lifting chain to the upper spreader bar and lower cylinder

assembly into excavation, making sure the PVC through hull fitting is

facing the front of the bay where pumping unit will be installed.

2. Secure cylinders to a finished height of 1/8” above finished floor grade.

Wooden 6” x 6” planks and 1/2” threaded rod help achieve proper

positioning. NOTE: Slope concrete away from lift in all directions.

3. Place a spirit level across the top of the pistons (not the cylinder

flanges) in two directions and adjust until pistons are plumb. Use a 6 ft.

level from one piston to the other to make sure they are level with each

other. Correct by adjusting as necessary.

4. Pour concrete around bases of both cylinders to a minimum of 10”

deep and 6” up the cylinders. (See Figure 3). Allow 24 hours for

concrete to cure.

5. Backfill with a clean dry washed sand fill to a level of 24” below floor

grade. Firmly tamp and check for plumbness frequently while

backfilling.

6. In the 9” deep trench from the pulley box to the wall where the pump

lines will be installed, use only 1-1/2” PVC electrical sweep as it makes

its turn up the wall to the pumping unit (leave the PVC sweep at least

6” above the floor grade to prevent water from entering the box).

7. Connect the PCV sweep fitting to pulley box assembly. NOTE: Make

sure to place an “O” ring gasket between the PVC fitting and the outer

surface of the pulley box assembly. Fully tighten the nut to prevent

leakage upon pouring of the concrete. (See Figure 5).

8. Complete backfill to a level of 9” below floor grade.

9. After rechecking plumbness in all directions, pour and finish concrete

making certain that cylinder flanges are 1/8” above finished grade.

Note: It is recommended to slightly taper concrete up the cylinder to

prevent any standing water around cylinder flange.

10. Install wheel-spotting dish in proper location. (See Figure 1 & 2).

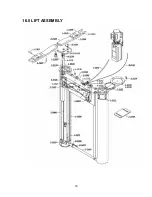

11. After allowing 48 hours for concrete to cure, attach lifting structures to

pistons and equalizer struts.

15

Summary of Contents for 40HP210ES

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

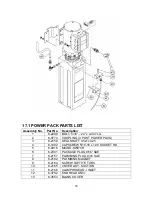

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...